Novel connecting piece laser welding double-pressure head

A technology of laser welding and connecting pieces, which is applied in the direction of laser welding equipment, welding equipment, electrical components, etc., can solve problems that affect the rectification of power battery pack power, hidden dangers of battery safety, and aging of tab sealing rings, so as to improve welding quality. efficiency and battery safety, improve welding effect, and avoid aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

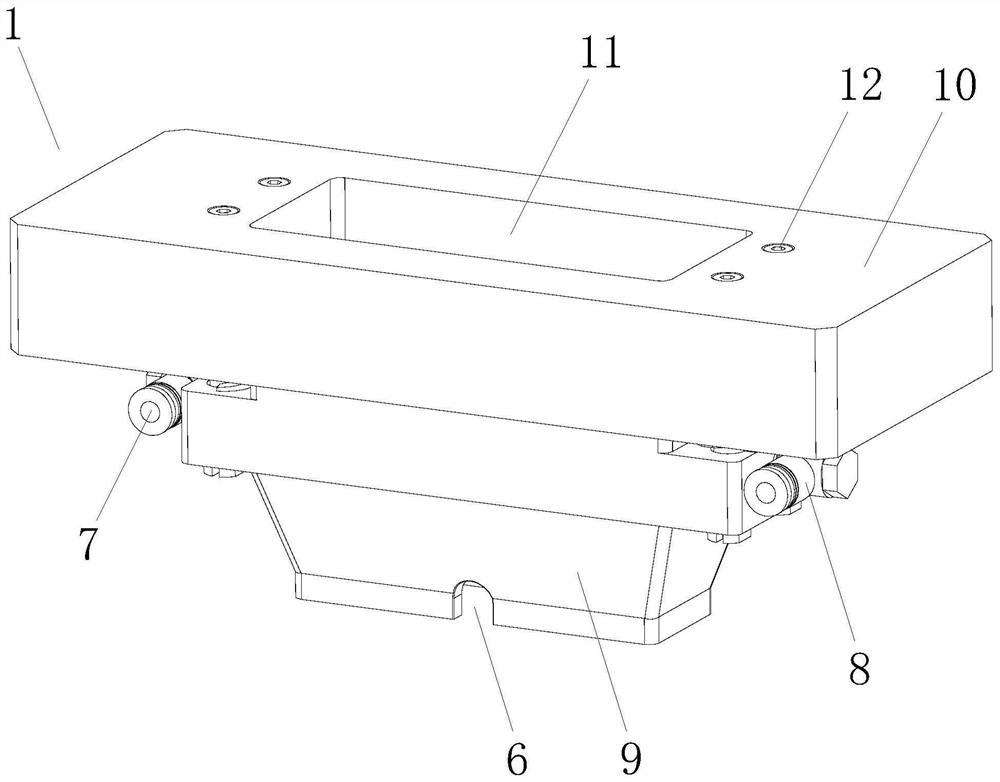

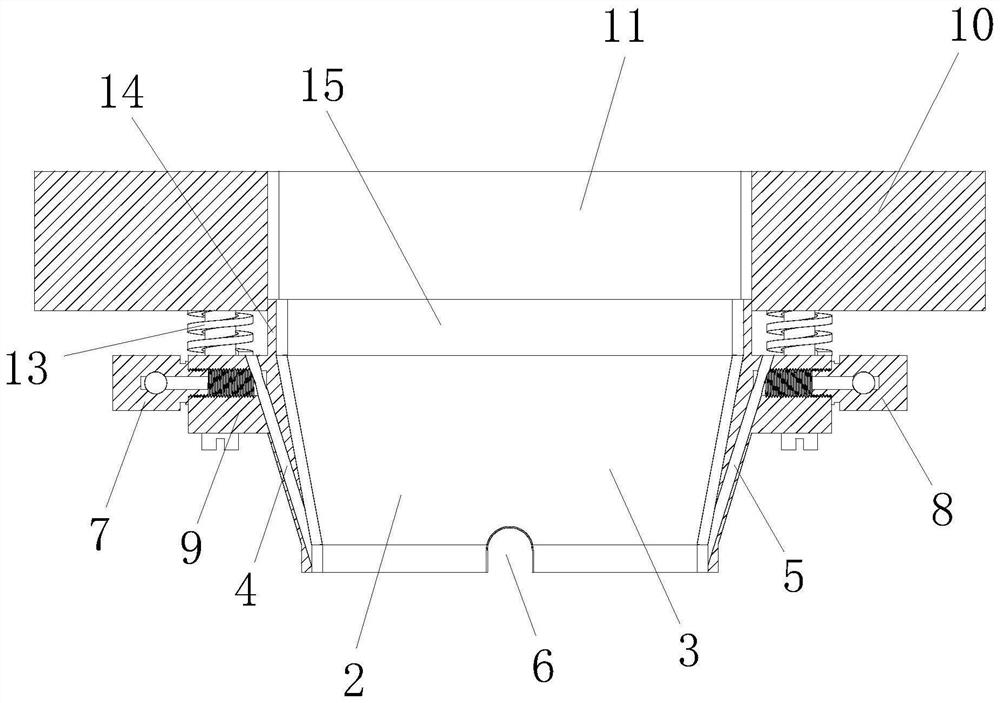

[0026] In order to further understand the content of the present invention, in conjunction with the attached Figure 1-2 And embodiment describe the present invention in detail.

[0027] combined with figure 1 and 2 , a new connecting piece laser welding double indenter of the present embodiment includes an indenter body 1, a first laser flow guide channel 2 is provided on the indenter body 1; a second laser guide channel 3; a first guide The flow channel 4 communicates with the first laser guide channel 2 and is used to feed inert gas into the first laser guide channel 2; the second guide channel 5 communicates with the second laser guide channel 3 and is used for feeding the first laser guide channel 2. The second laser diversion channel 3 leads to the inert gas; the diversion port 6 is used for the discharge of the inert gas and the welding slag; contact position.

[0028] The laser welding double pressure head of the new connecting piece continuously injects inert gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com