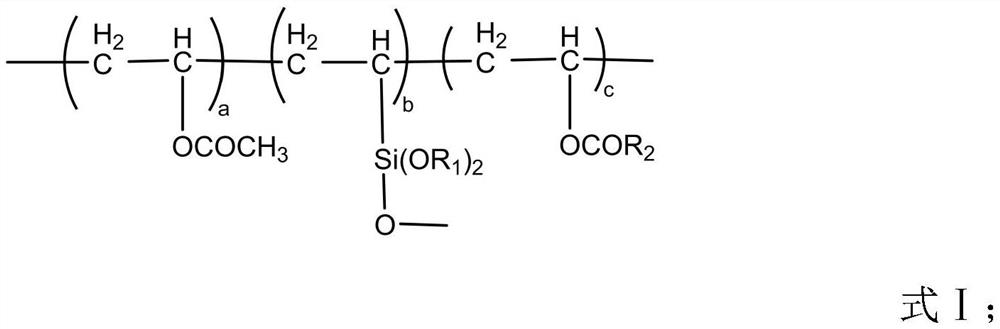

Organic silicon modified vinyl acetate ternary composition and preparation method thereof

A vinyl acetate, ternary composition technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of difficulty in fully reflecting the excellent characteristics of silicone, the influence of emulsion storage stability, and the inability to meet high-end requirements, and achieve high and low temperature resistance. Good performance, low price, low surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

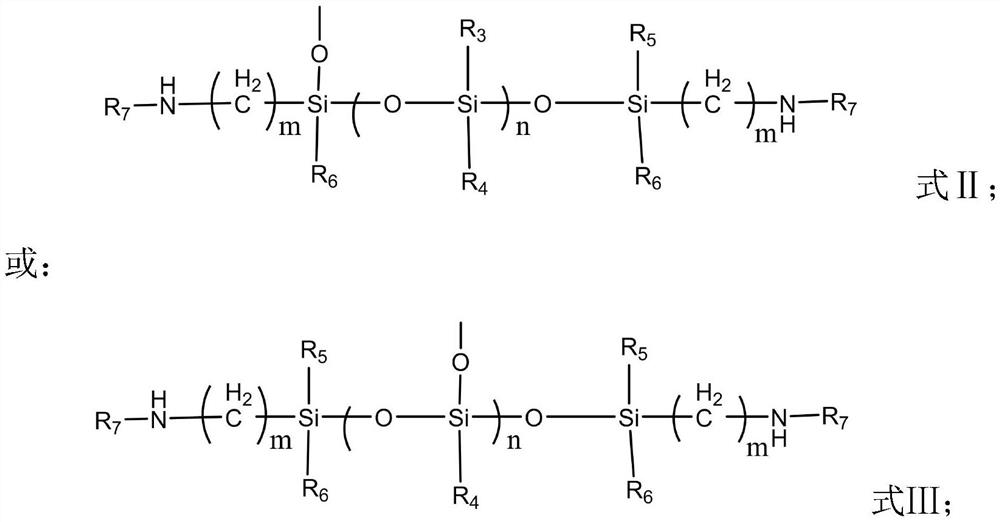

[0065] First, 50 parts of vinyl acetate, 10 parts of vinyltrimethoxysilane, 5 parts of vinyl nonanoate and 5 parts of azobisisobutyronitrile initiator were mixed at room temperature to obtain monomer mixture I.

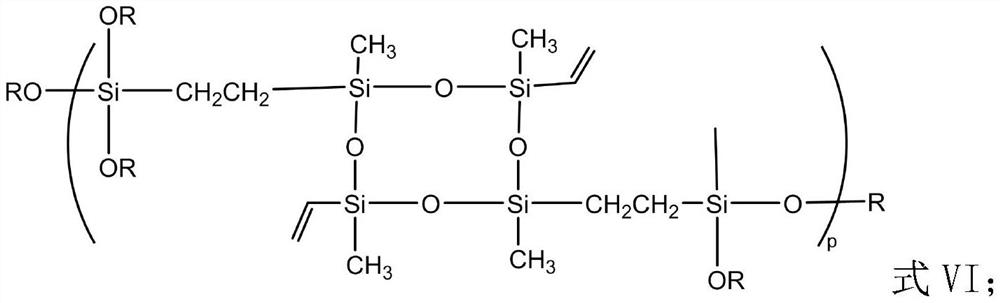

[0066] Then, weigh 5 parts of aminopropyldimethoxysiloxane-terminated polymethylmethoxysiloxane oligomer with chain number (n=40, m=2), 3 parts with chain number ( p=40) methoxy hyperbranched siloxane was mixed with 1 part of azobisisobutyronitrile initiator to prepare monomer mixture II.

[0067] Add the monomer mixture I into a 500ml four-neck flask equipped with a stirrer and a condensing device, and apply a nitrogen layer (10L / h). The stirring speed of the stirrer was set at 80 r / min, and the reaction temperature in the reactor was set at 125°C. Once the temperature in the reactor was reached, monomer mixture II was fed into the reactor over 4 hours.

[0068] Finally, 1 part of azobisisobutyronitrile initiator was added as a booster within one hour and incubated...

Embodiment 2

[0076] First, 50 parts of vinyl acetate, 10 parts of vinyltriethoxysilane, 5 parts of vinyl caprate and 5 parts of azobisisovaleronitrile initiator were uniformly mixed at room temperature to obtain monomer mixture I.

[0077] Then, weigh 5 parts of polymethylpropoxysiloxane oligomer terminated by aminophenyldiethylsiloxane with chain number (n=45, m=3), 4 parts with chain number (p =60) Methoxy hyperbranched siloxane is mixed with 1 part of azobisisobutyronitrile initiator to obtain monomer mixture II.

[0078] Add the monomer mixture I into a 500ml four-neck flask equipped with a stirrer and a condensing device, and apply a nitrogen layer (10L / h). The stirring speed of the stirrer was set at 80 r / min, and the reaction temperature in the reactor was set at 125°C. Once the temperature in the reactor was reached, monomer mixture II was fed into the reactor over 4 hours.

[0079] Finally, 1 part of azobisisoheptanonitrile initiator was added as a booster within one hour and in...

Embodiment 3

[0085] First, 60 parts of vinyl acetate, 3 parts of vinyltriethoxysilane, 5 parts of vinyl caprate and 5 parts of azobisisoheptanonitrile initiator were mixed to prepare monomer mixture I.

[0086] Then, weigh 6 parts of polypropylethoxysiloxane oligomers terminated with aminopropylmethylethoxysiloxane (n=50, m=4), 3.9 parts of chain members (p=4) 50) Mix methoxy hyperbranched siloxane with 1 part of dimethyl azobisisobutyrate initiator to prepare monomer mixture II.

[0087] Add the monomer mixture I into a 500ml four-neck flask equipped with a stirrer and a condensing device, and apply a nitrogen layer (10L / h). The stirrer is set at 80r / min, and the temperature is set at 120°C. Once the temperature in the reactor was reached, monomer mixture II was fed into the reactor over 4 hours.

[0088] Finally, 1 part of lauroyl peroxide initiator was added as a booster within one hour and incubated at 120°C for one hour. Finally, it is cooled to below 80°C to prepare a ternary comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com