Surface-treated copper foil, carrier-attached copper foil, copper-clad laminate, and printed wiring board

A printed circuit board, surface treatment technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve the problems of circuit peeling, circuit and insulation layer adhesion reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

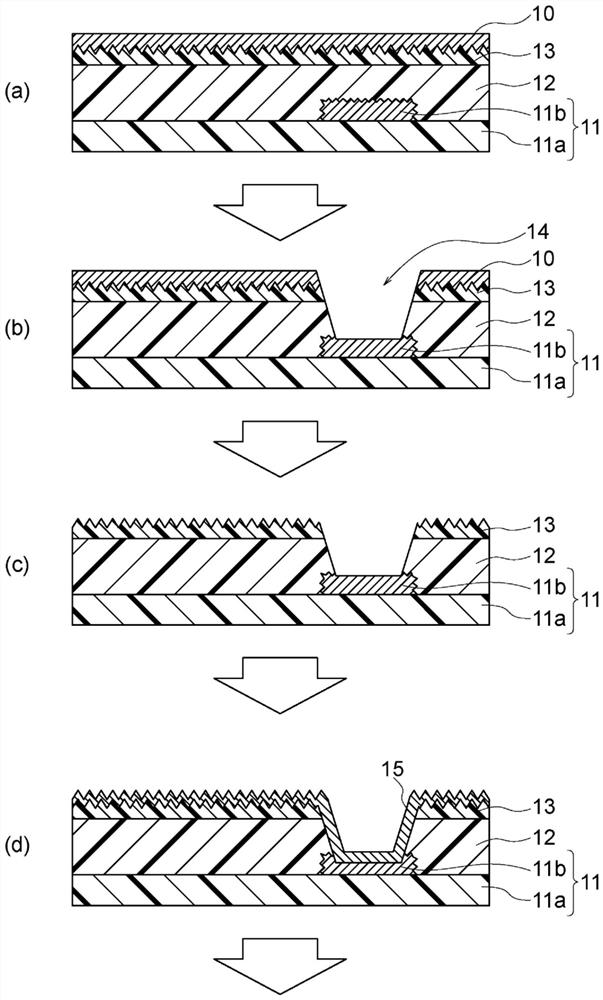

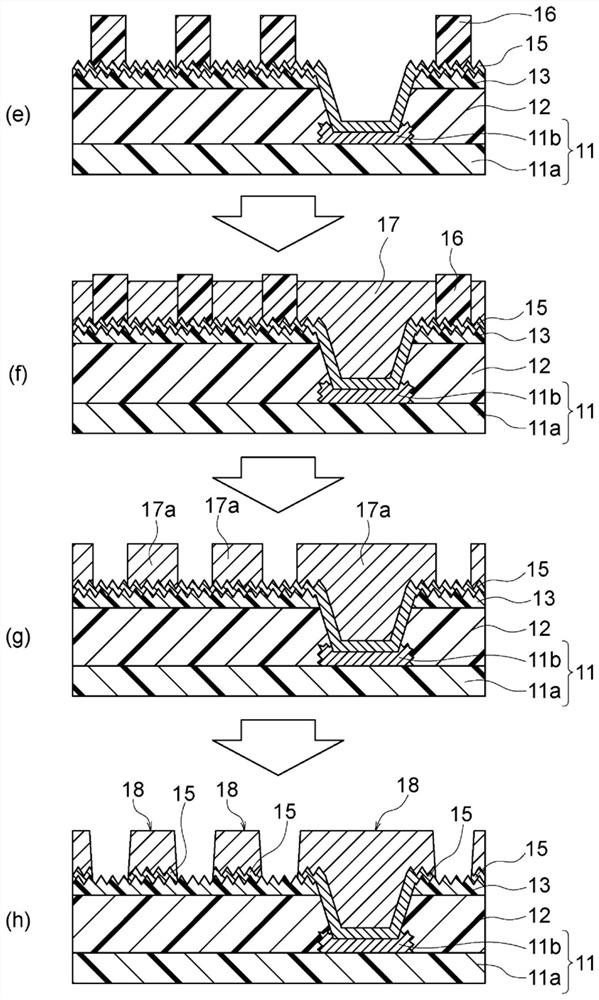

Method used

Image

Examples

Embodiment

[0079] The present invention is further specifically described by the following examples.

example 1~6

[0081] Preparation and evaluation of the copper foil with a carrier and the resin replica sample were performed as follows.

[0082] (1) Production of carrier

[0083] As a cathode, a titanium electrode whose surface was ground with a #2000 buff was prepared. In addition, DSA (dimensionally stable anode) was prepared as an anode. Using these electrodes, immersed in a copper sulfate solution with a copper concentration of 80g / L and a sulfuric acid concentration of 260g / L, at a solution temperature of 45°C and a current density of 55A / dm 2 Electrolysis was carried out to obtain an electrolytic copper foil having a thickness of 18 μm as a carrier.

[0084] (2) Formation of peeling layer

[0085] In a CBTA aqueous solution having a CBTA (carboxybenzotriazole) concentration of 1 g / L, a sulfuric acid concentration of 150 g / L, and a copper concentration of 10 g / L, the electrode surface side of the acid-washed carrier was immersed for 30 seconds at a liquid temperature of 30° C. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com