Solid dairy product and preparation method thereof

A technology for dairy products and solid state, which is applied in the field of solid dairy products and their preparation to achieve the effects of not being easy to dry and harden, reducing water activity, and having a uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

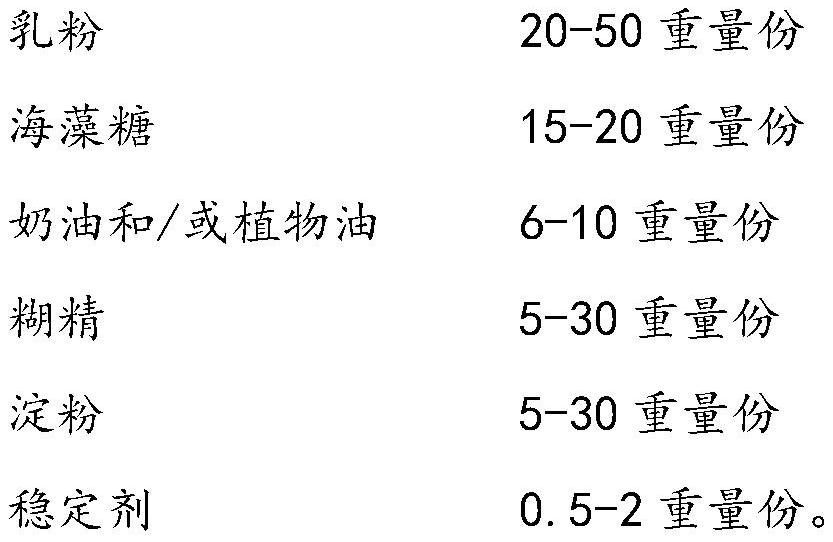

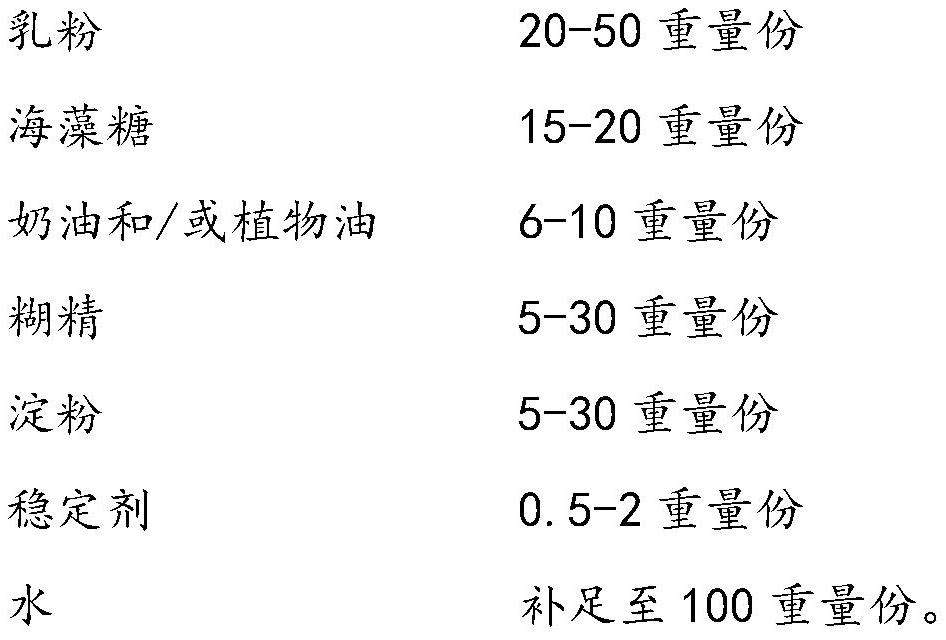

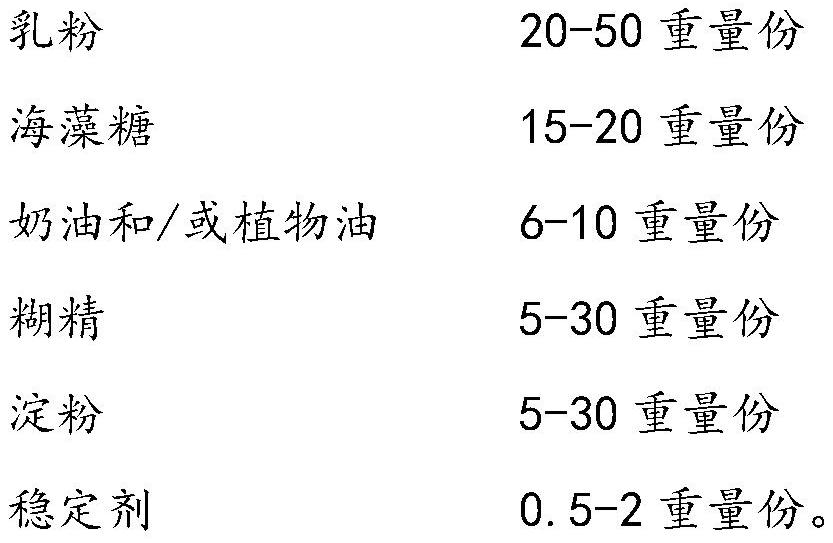

[0037] The raw material formula of the solid dairy product in this example is: 20 parts by weight of milk powder, 15 parts by weight of trehalose, 10 parts by weight of anhydrous cream, 30 parts by weight of dextrin, 10 parts by weight of starch, 2 parts by weight of stabilizer, and 13 parts by weight of water share.

[0038] Wherein, based on the total weight of the stabilizer, the stabilizer includes 10 wt% of mono- and diglycerin fatty acid esters, 19.8 wt% of polyglycerol fatty acid esters, 0.2 wt% of carrageenan, 50 wt% of phospholipids, and 20 wt% of sodium caseinate.

[0039] The preparation method of the solid dairy product of this embodiment includes,

[0040] Weigh the raw materials according to the recipe.

[0041] Dry-mix the milk powder, trehalose, dextrin and starch of the formula amount for 5 minutes to obtain the mixture 1;

[0042] Mix the amount of water and anhydrous butter in the recipe and heat it to 60°C, then add a stabilizer and stir for 10 minutes, t...

Embodiment 2

[0050] The raw material formula of the solid dairy product in this example is: 30 parts by weight of milk powder, 20 parts by weight of trehalose, 9 parts by weight of anhydrous butter, 5 parts by weight of dextrin, 20 parts by weight of starch, 1.5 parts by weight of stabilizer, and 14.5 parts by weight of water share.

[0051] Wherein, based on the total weight of the stabilizer, the stabilizer includes 29.7 wt% of mono- and diglycerin fatty acid ester, 10 wt% of polyglycerol fatty acid ester, 0.3 wt% of carrageenan, 20 wt% of phospholipid, and 40 wt% of sodium caseinate.

[0052] The preparation method of the solid dairy product of this embodiment includes,

[0053] Weigh the raw materials according to the recipe.

[0054] Dry-mix the milk powder, trehalose, dextrin and starch of the formula amount for 6 minutes to obtain the mixture 1;

[0055] Mix the amount of water and anhydrous butter in the formula and heat it to 57°C, then add a stabilizer and stir for 15 minutes, ...

Embodiment 3

[0063] The raw material formula of the solid dairy product in this example is: 25 parts by weight of milk powder, 18 parts by weight of trehalose, 7 parts by weight of anhydrous butter, 10 parts by weight of dextrin, 25 parts by weight of starch, 1 part by weight of stabilizer, and 14 parts by weight of water share.

[0064] Wherein, based on the total weight of the stabilizer, the stabilizer includes 20 wt% of mono- and diglycerin fatty acid esters, 30 wt% of polyglycerol fatty acid esters, 0.4 wt% of carrageenan, 30 wt% of phospholipids, and 19.6 wt% of sodium caseinate.

[0065] The preparation method of the solid dairy product of this embodiment includes,

[0066] Weigh the raw materials according to the recipe.

[0067]Dry mix the milk powder, trehalose, dextrin and starch of the formula amount for 8 minutes to obtain the mixture 1;

[0068] Mix the amount of water and anhydrous butter in the formula and heat it to 55°C, then add a stabilizer and stir for 20 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com