A gas-solid short contact time reaction device and its application

A technology of contact time and reaction device, which is applied in the direction of climate sustainability, bulk chemical production, condensation hydrocarbon production with dehydrocarbons, etc. Solve problems such as single means, achieve the effects of reducing gas-solid contact time, improving energy utilization rate, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

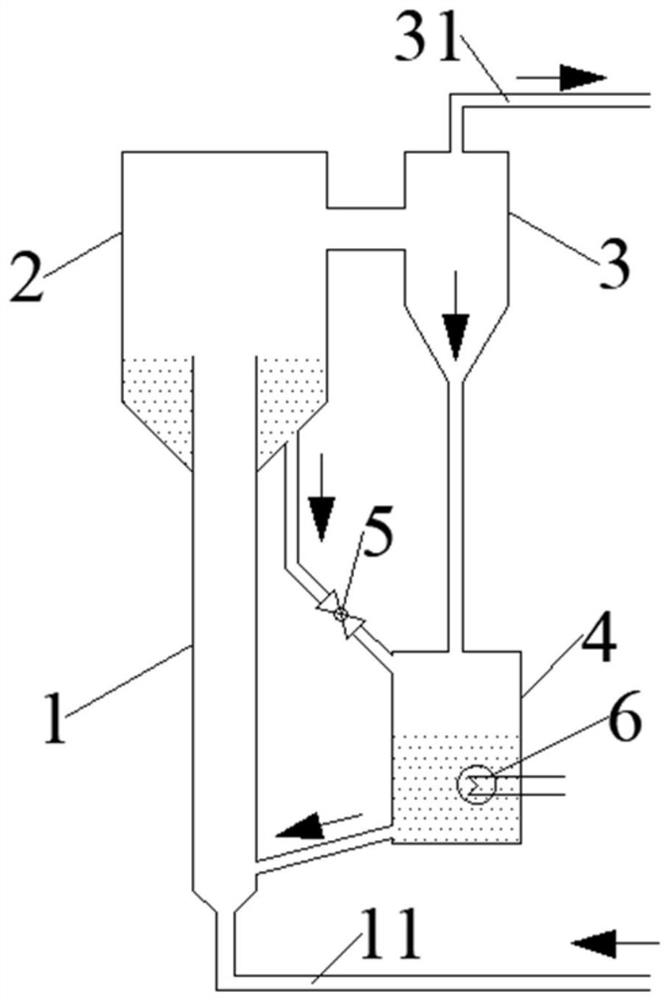

[0067] This embodiment provides a figure 1 The reaction device with short gas-solid contact time shown includes a riser reactor 1 , a settling reactor 2 , a gas-solid separator 3 and a feeding device 4 .

[0068] The riser reactor 1 is installed at the bottom of the settling reactor 2, and the discharge port of the riser reactor 1 is higher than the bottom discharge port of the settling reactor 2;

[0069] The gas-solid separator 3 is used for the separation of product gas and catalyst particles in the product of the settling reactor 2;

[0070] The feeding device 4 collects the catalyst particles transported by the bottom outlet and the catalyst particles obtained by the gas-solid separator 3, and returns the collected catalyst particles to the bottom of the riser;

[0071] The bottom of the riser is provided with a feed gas inlet pipe 11 .

[0072] A flow control device 5 is provided on the return material pipeline connecting the bottom discharge port and the return materi...

Embodiment 2

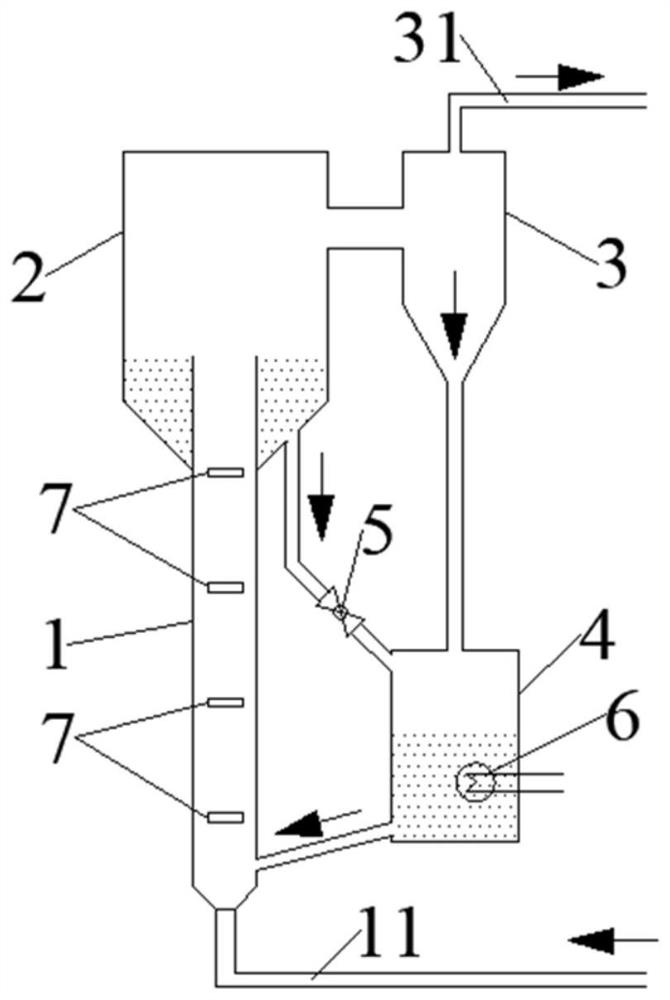

[0076] This embodiment provides a figure 2 The reaction device with short gas-solid contact time shown includes a riser reactor 1 , a settling reactor 2 , a gas-solid separator 3 and a feeding device 4 .

[0077] The riser reactor 1 is installed at the bottom of the settling reactor 2, and the discharge port of the riser reactor 1 is higher than the bottom discharge port of the settling reactor 2;

[0078] The gas-solid separator 3 is used for the separation of product gas and catalyst particles in the product of the settling reactor 2;

[0079] The feeding device 4 collects the catalyst particles transported by the bottom outlet and the catalyst particles obtained by the gas-solid separator 3, and returns the collected catalyst particles to the bottom of the riser;

[0080] The bottom of the riser is provided with a feed gas inlet pipe 11 .

[0081] Four oxygen distributors 7 are evenly arranged in the riser.

[0082] A flow control device 5 is provided on the return mate...

Embodiment 3

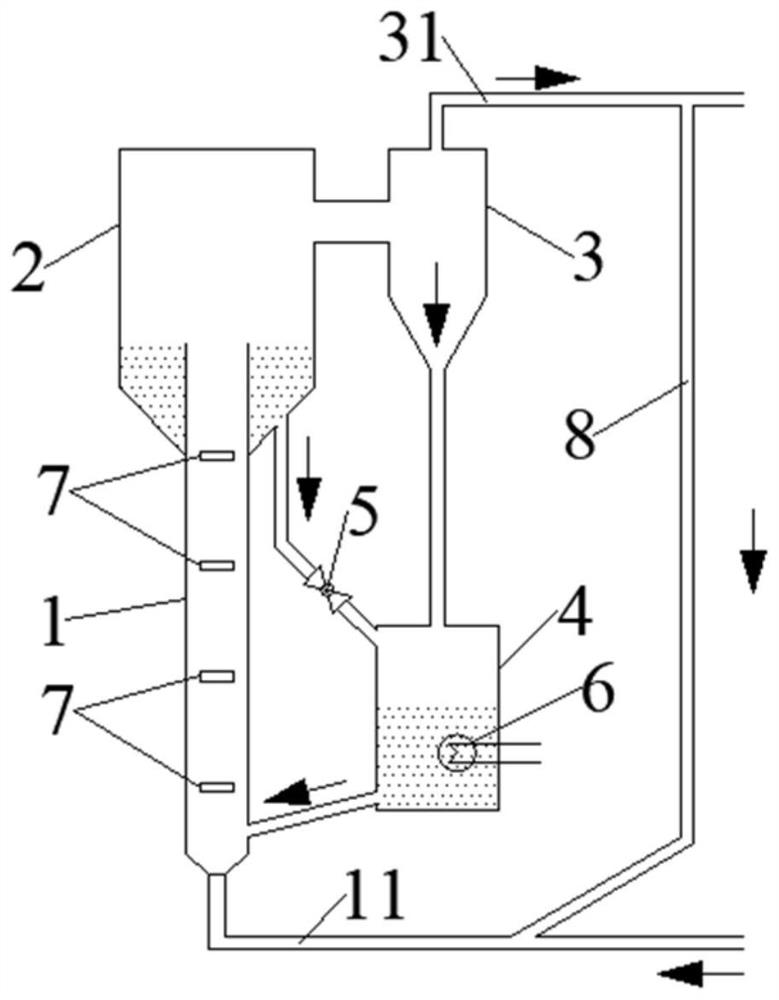

[0087] This embodiment provides a image 3 The reaction device with short gas-solid contact time shown includes a riser reactor 1 , a settling reactor 2 , a gas-solid separator 3 and a feeding device 4 .

[0088] The riser reactor 1 is installed at the bottom of the settling reactor 2, and the discharge port of the riser reactor 1 is higher than the bottom discharge port of the settling reactor 2;

[0089] The gas-solid separator 3 is used for the separation of product gas and catalyst particles in the product of the settling reactor 2;

[0090] The feeding device 4 collects the catalyst particles transported by the bottom outlet and the catalyst particles obtained by the gas-solid separator 3, and returns the collected catalyst particles to the bottom of the riser;

[0091] The bottom of the riser is provided with a feed gas inlet pipe 11 .

[0092] Four oxygen distributors 7 are evenly arranged in the riser.

[0093] A flow control device 5 is provided on the return mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com