Catalyst with isolated dehydrogenation and oxidation double active sites and preparation and application thereof

A catalyst and dual-activity technology, applied in the field of catalytic conversion of low-carbon alkanes, can solve the problems of catalyst activity decline, shortened service life, catalyst poisoning failure, etc., and achieve high ethane adsorption and activation ability, high catalytic decomposition ability, and full combustion ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

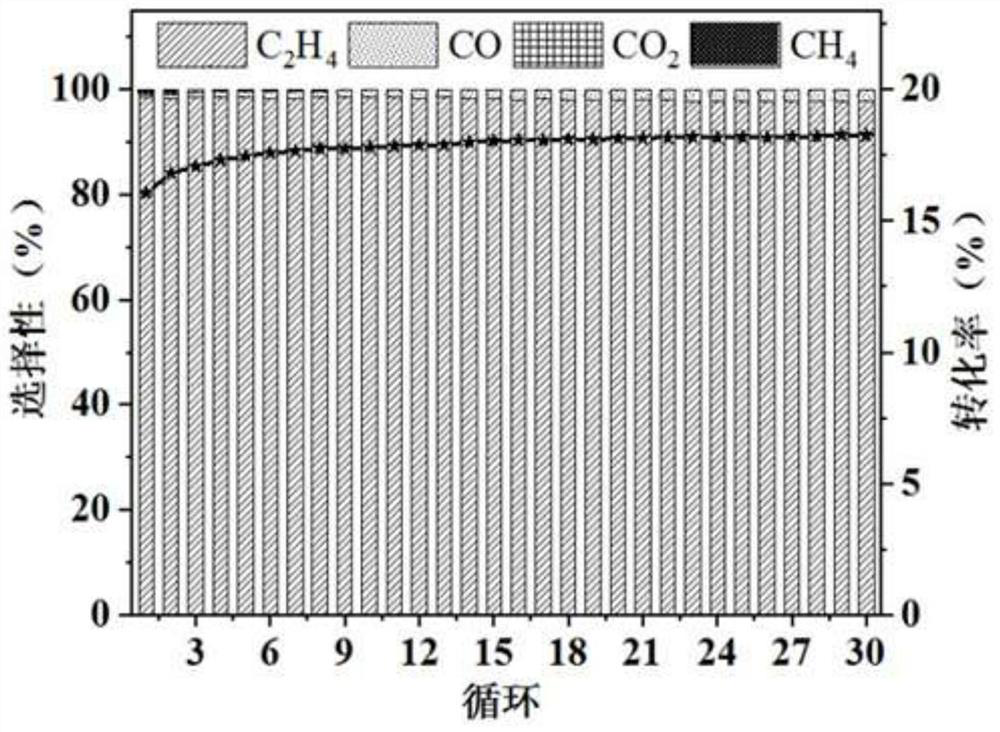

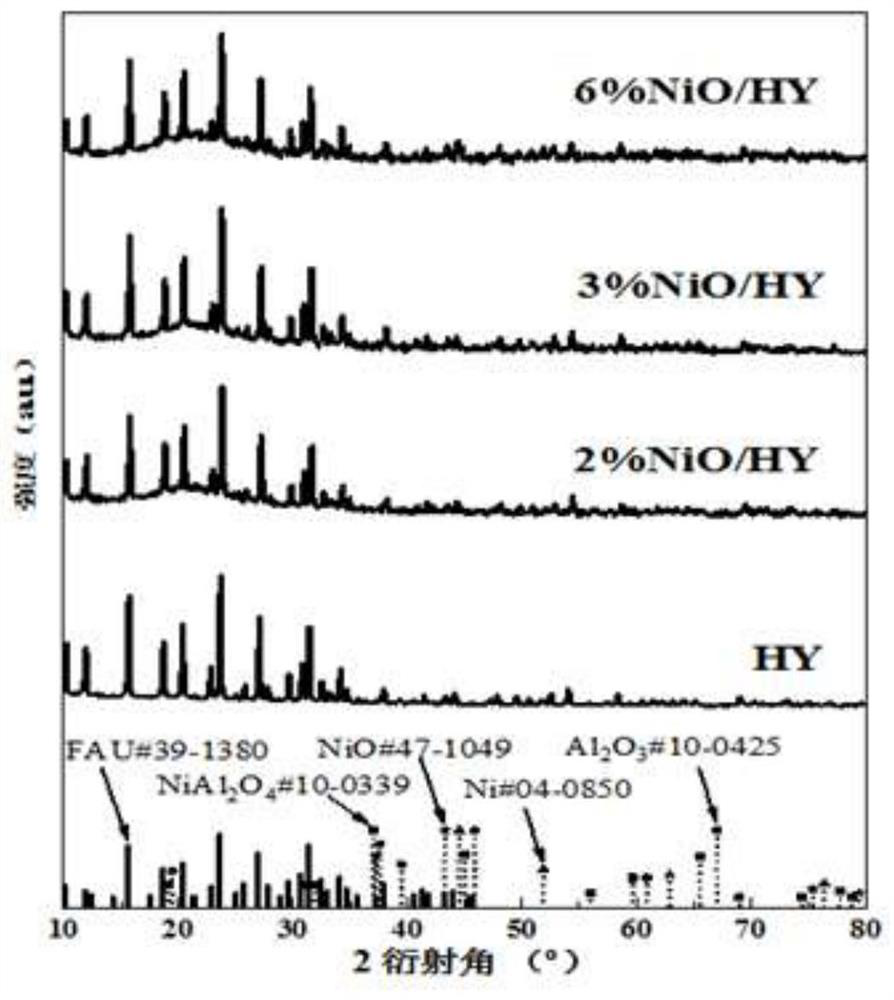

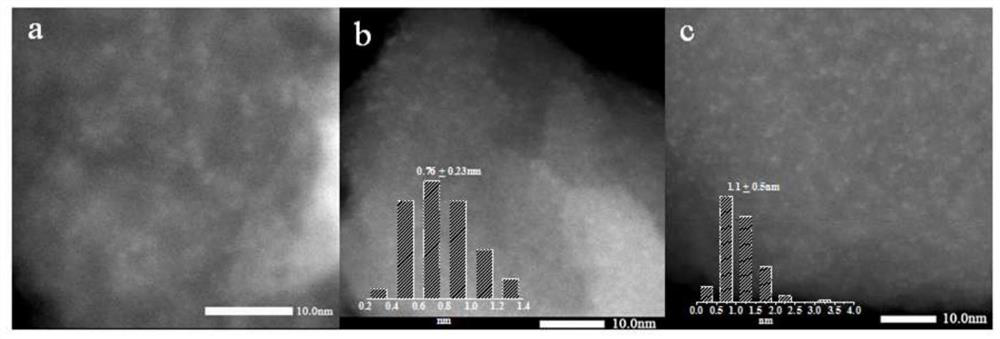

[0037] Weigh 0.467g of nickel nitrate and place it in a beaker, add 3ml of ultrapure water, ultrasonically disperse, and then add 3.88g of HY molecular sieve carrier (SiO 2 / Al 2 O 3 =5 molar ratio), stop stirring after stirring uniformly. After standing for 12 hours, it was put into a drying oven and dried at 60°C and 120°C for 12 hours respectively. After drying, the catalyst was calcined at 600 °C for 4 h in an air atmosphere to obtain a 3 wt.% NiO / HY catalyst. The active metal loading of the catalyst is 3% of the catalyst mass, and contains two active sites, NiLewis acids, an active metal supported on the surface of the molecular sieve, and its metal oxide nanoclusters (1-2 nm) confined in the pores of the molecular sieve. The molar ratio of metal Ni Lewis acids to metal oxide confined in the zeolite channels was 3.7. Take 1 g of catalyst and add it to the fixed-bed reactor, heat it up to 600°C under an inert atmosphere He, and feed 10% C after the temperature is stabl...

Embodiment 2-3

[0049] Weigh 3.96g, 3.92g HY molecular sieve (SiO 2 / Al 2 O3 =5 molar ratio), respectively add 3 ml of nickel nitrate aqueous solution to it, so that the mass loadings of metal oxides are respectively 1% and 2%, and the stirring is stopped after stirring evenly. After standing for 12 h, drying at 60 °C and 120 °C for 12 h respectively, and calcining at 600 °C for 4 h in an air atmosphere, the catalyst was prepared. Take 1 g of catalyst and add it to the fixed-bed reactor, heat it up to 600°C under an inert atmosphere He, and feed 10% C after the temperature is stable. 2 H 6 / He, the flow rate was 150ml / min, the reaction tail gas was quantitatively detected by online infrared, and switched to He gas purging after 30sec. The cumulative product distribution is shown in Table 2.

[0050] In Examples 2 and 3, the catalyst active metal loadings were 1% and 2% of the catalyst mass, respectively, containing the active metal Ni Lewis acids supported on the surface of the molecular s...

Embodiment 4、5

[0055] Weigh 3.96g and 3.88g of HY molecular sieve (SiO 2 / Al 2 O 3 =5 molar ratio), respectively add 3 ml of cobalt nitrate aqueous solution to it, so that the mass loading of the metal oxide is 1% and 3% respectively, and the stirring is stopped after stirring evenly. After standing for 12 hours, it was put into a drying oven and dried at 60°C and 120°C for 12 hours respectively. After drying, the catalyst was calcined at 600 °C for 4 h in an air atmosphere to obtain the catalyst. Take 1 g of catalyst and add it to the fixed-bed reactor, heat it up to 600°C under an inert atmosphere He, and feed 10% C after the temperature is stable. 2 H 6 / He, the flow rate was 150ml / min, the reaction tail gas was quantitatively detected by online infrared, and switched to He gas purging after 30sec. The cumulative product distribution is shown in Table 2.

[0056] In Examples 4 and 5, the active metal loadings of the catalysts were 1% and 3% of the catalyst mass, respectively, contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com