Perovskite TiSrCo Catalyst for Hydrogen Production by Autothermal Reforming of Acetic Acid

A perovskite type, autothermal reforming technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst deactivation, and achieve Effects of reduced activation energy, stable activity, and high hydrogen yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Weigh 2.107g of Co(NO 3 ) 2 ·6H 2 O, add 30.0ml of deionized water, stir at room temperature for 30min to prepare #1 solution; then weigh 14.494g of C 16 h 36 o 4 Ti, add 3.0ml of hydrochloric acid (35%) and 9.3ml of anhydrous acetic acid, fully stir at room temperature for 30min to dissolve, and obtain #2 solution; then weigh 2.890g of P123 solution, add 30.0ml of absolute ethanol, Stir at room temperature for 30 minutes to prepare #3 solution; slowly drop #1 solution into #3 solution, stir for 30 minutes, then slowly drop the obtained solution into #2 solution, stir at 40°C for 3 hours, let stand, Gel forming; put the obtained gel into an oven at 65°C and dry for 48 hours; then bake the dried sample at 600-800°C for 4 hours, press into tablets, and sieve to obtain the catalyst CDUT-LHG-TC, The composition is TiCoO 3 . The weight percent composition of the catalyst is: 15.0% of cobalt oxide and 85.0% of titanium dioxide.

[0030] The evaluation of autothermal r...

Embodiment 1

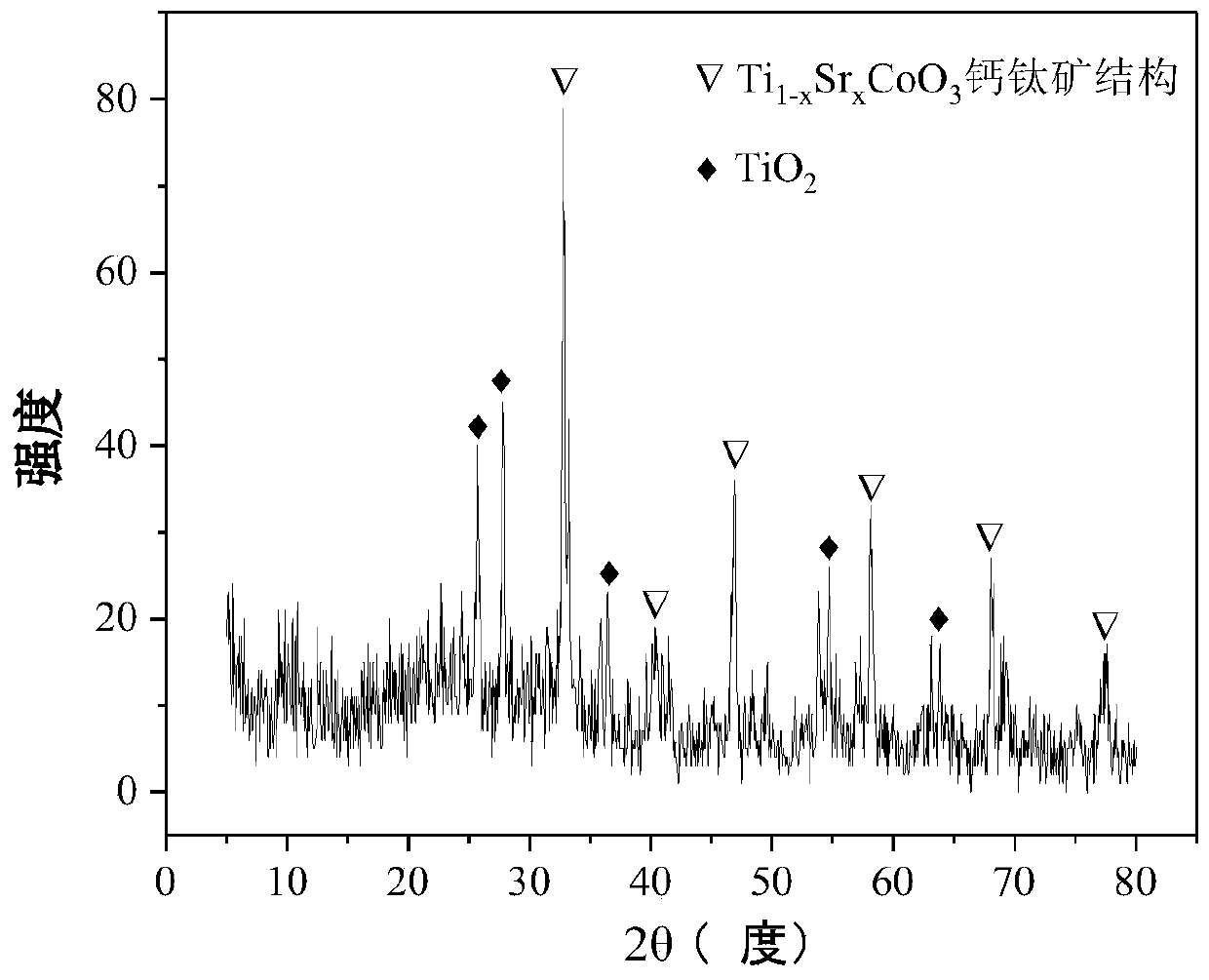

[0033] Weigh 2.106g of Co(NO 3 ) 2 ·6H 2 O and 1.701 g of SrNO 3 , add 30.0ml of deionized water, stir at room temperature for 30min to prepare #1 solution; then weigh 10.945g of C 16 h 36 o 4 Ti, add 2.3ml of hydrochloric acid (35%) and 7.0ml of anhydrous acetic acid, fully stir at room temperature for 30min to dissolve, and obtain #2 solution; then weigh 2.751g of P123 solution, add 30.0ml of absolute ethanol, Stir at room temperature for 30 minutes to prepare #3 solution. Subsequent steps are the same as in reference example 1 to obtain catalyst CDUT-LHG-TSC-1, the composition of which is Ti 0.8 Sr 0.2 CoO 3 , its XRD pattern is attached figure 1 , indicating that the catalyst formed a typical perovskite structure and a small amount of TiO 2 . The weight percent composition of the catalyst is: 15.0% of cobalt oxide, 64.2% of titanium dioxide and 20.8% of strontium oxide.

[0034] The CDUT-LHG-TSC-1 catalyst was investigated for the activity of autothermal reform...

Embodiment 2

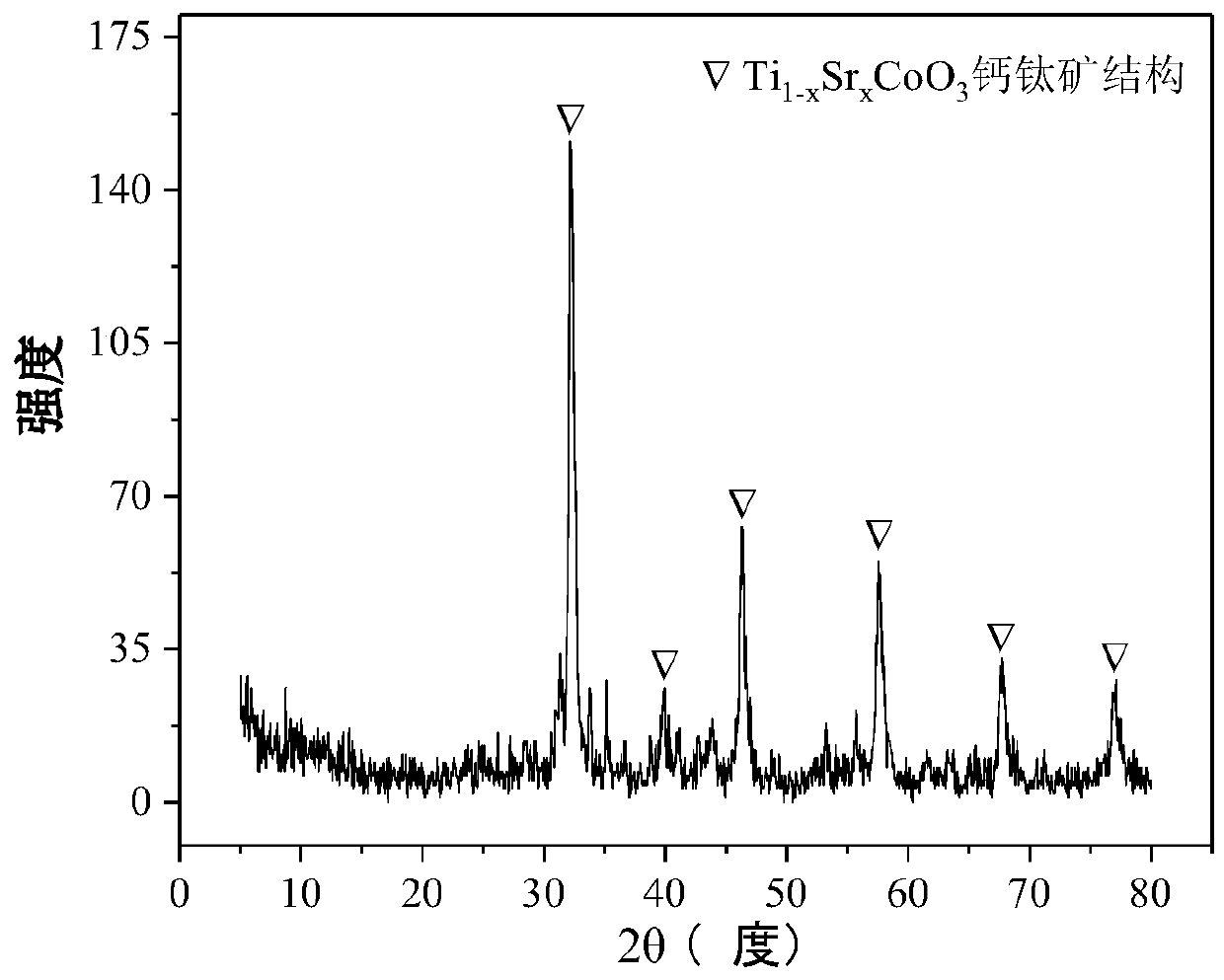

[0036] Weigh 2.108g of Co(NO 3 ) 2 ·6H 2 O and 3.918g of SrNO 3 , add 30.0ml of deionized water, stir at room temperature for 30min to prepare #1 solution; then weigh 6.302g of C 16 h 36 o 4 Ti, add 1.48ml of hydrochloric acid (35%) and 4.6ml of anhydrous acetic acid, fully stir at room temperature for 30min to dissolve, and obtain #2 solution; then weigh 2.930g of P123 solution, add 30.0ml of absolute ethanol, Stir at room temperature for 30 minutes to prepare #3 solution. Subsequent steps are with reference example 1, obtain catalyst CDUT-LHG-TSC-2, and its composition is Ti 0.5 Sr 0.5 CoO 3 , and its typical XRD pattern is attached figure 2 , indicating that the catalyst formed a typical perovskite structure Ti 1-x Sr x CoO 3 , The weight percent composition of the catalyst is: cobalt oxide 15.0%, titanium dioxide 37.0%, strontium oxide 48.0%.

[0037] The CDUT-LHG-TSC-2 catalyst was investigated for the activity of autothermal reforming of acetic acid. The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com