Aporous ceramic supported iron-based Fischer-Tropsch catalyst and using method of the catalyst

A technology of porous ceramics and catalysts, which is applied in the field of porous ceramics-supported iron-based Fischer-Tropsch catalysts, can solve the problems of low activity and selectivity at low temperature, and achieves the promotion of iron reduction, high activity and low carbon olefin selectivity, and avoidance of accumulation. effect of carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

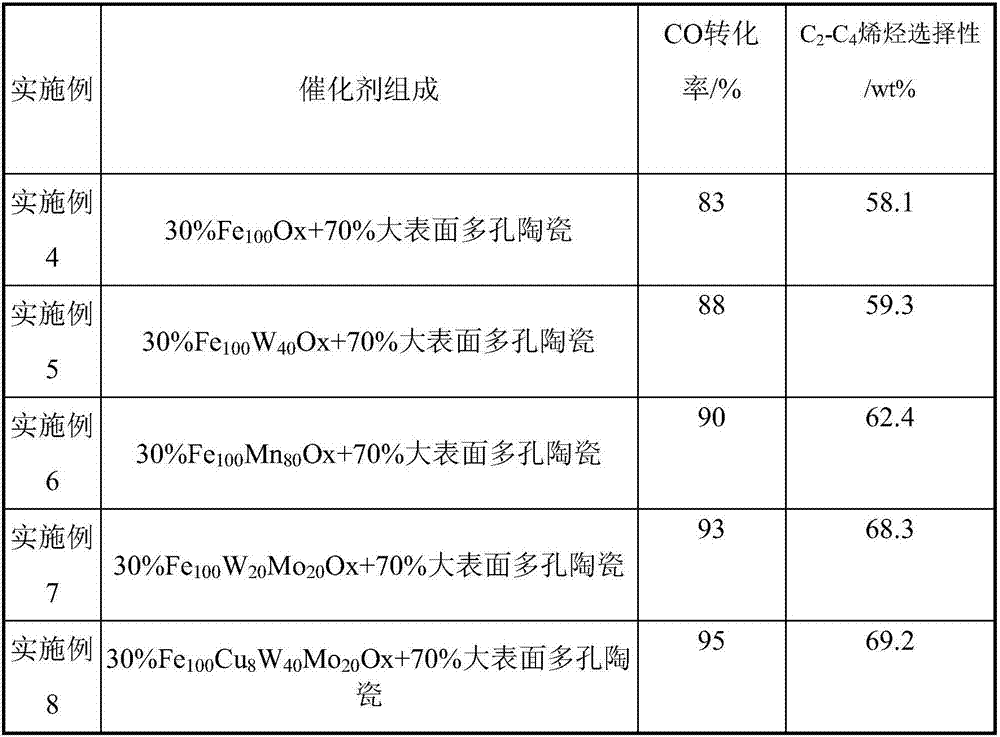

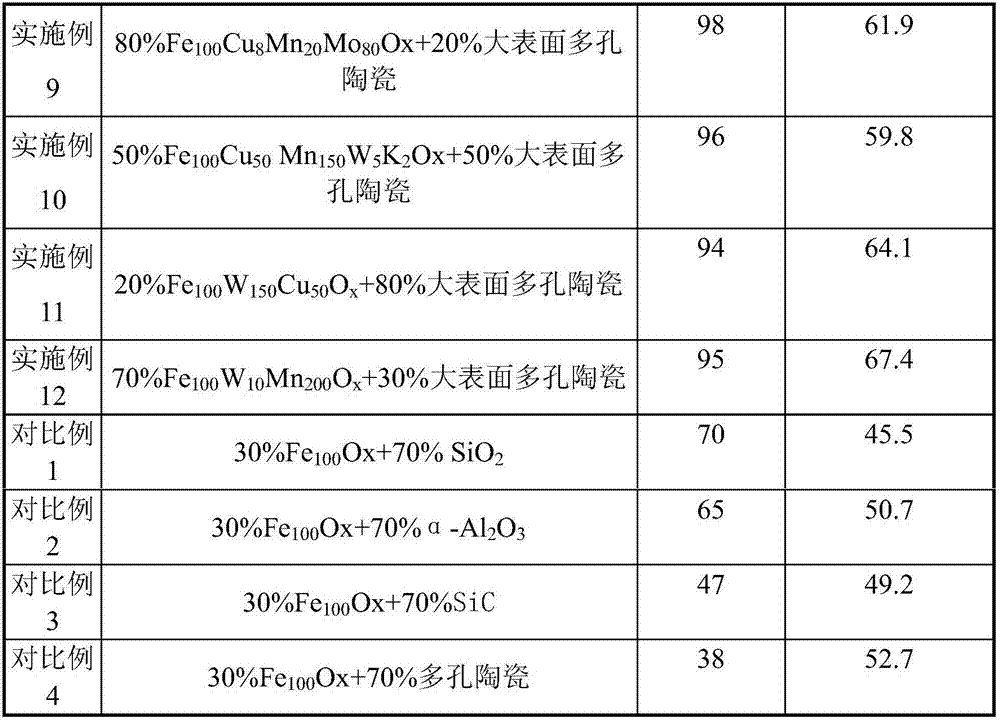

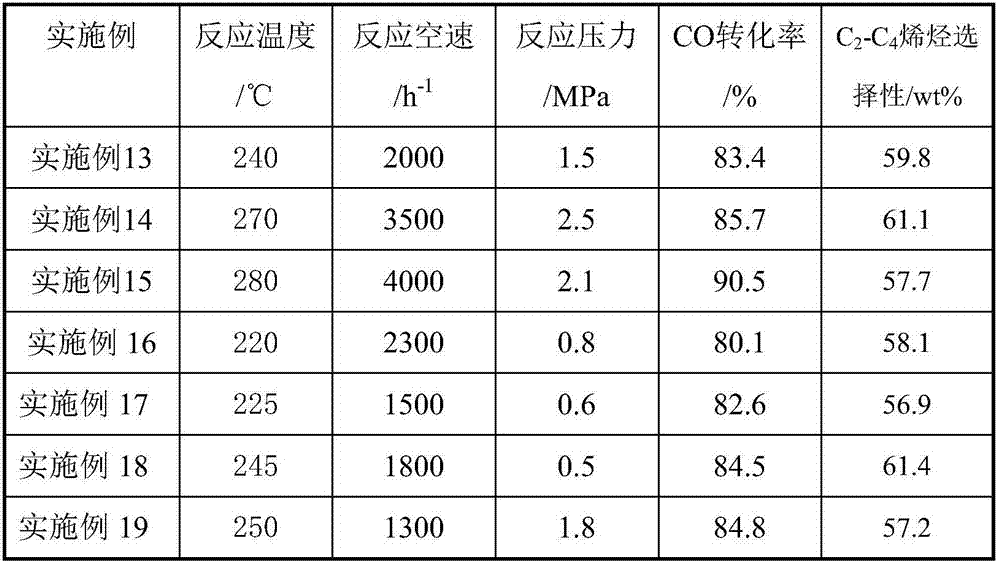

Examples

Embodiment 1

[0049] Weigh 30 grams of methylamine, 70 grams of propylamine and 200 grams of deionized water, mix them into a solution and add them to the reactor, then weigh 100 grams of porous ceramics containing 0.25% iron oxide and 0.25% zinc oxide, add them to the reactor, seal Raise the temperature to 160°C, react for 24 hours, then cool down to room temperature, filter the solid, dry at 100°C for 5 hours, and then bake at 400°C for 12 hours.

Embodiment 2

[0051] Weigh 200 grams of ethylenediamine and 100 grams of deionized water, mix them into a solution and add them to the reaction kettle, then weigh 10 grams of porous ceramics containing 15% iron oxide, add them to the reaction kettle, seal and heat up to 170°C, and react for 12 hours After cooling down to room temperature, the solid was filtered and dried at 80°C for 24 hours, and then calcined at 500°C for 8 hours.

Embodiment 3

[0053] Weigh 30 grams of ethylamine, 77 grams of butylamine, 170 grams of triethylamine and 23 grams of deionized water, mix them into a solution and add them to the reaction kettle, then weigh 6 grams of porous ceramics containing 0.6% cobalt oxide and 2.4% nickel oxide , added to the reaction kettle, sealed and heated to 250°C, reacted for 72 hours and then lowered to room temperature, filtered the solid and dried at 120°C for 2 hours, and then roasted at 800°C for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com