Preparation method of manganese-cerium oxide catalyst for removing formaldehyde at room temperature

A catalyst and oxide technology, applied in the field of preparation of manganese cerium oxide catalyst, can solve the problems of low formaldehyde removal rate and the like, and achieve the effects of simple preparation process, enhanced reducibility and promotion of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

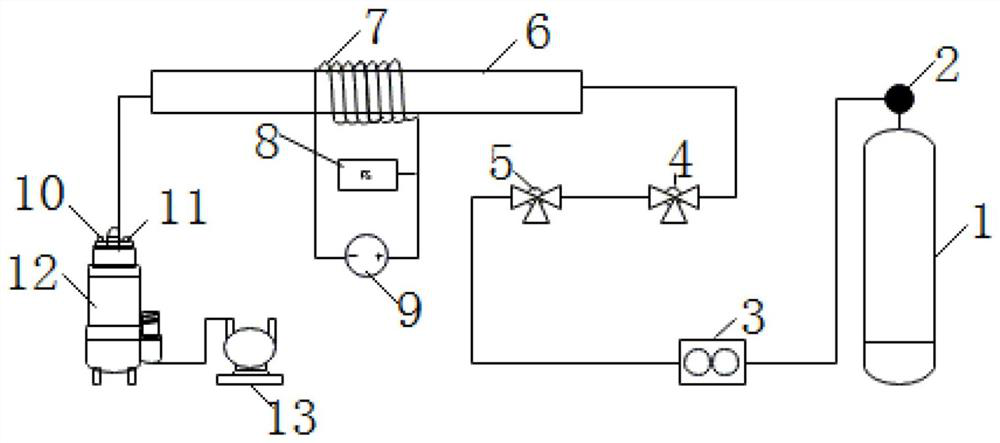

Image

Examples

preparation example Construction

[0026] A kind of preparation method of manganese cerium oxide catalyst that removes formaldehyde at room temperature is characterized in that, comprises the steps:

[0027] Step 1, preparation of catalyst precursor

[0028] Add cerium nitrate and potassium permanganate in deionized water in sequence, place in a constant temperature magnetic stirring apparatus and stir for 0.5 h until fully dissolved to obtain a raw material solution, wherein the molar ratio of Mn / Ce in the raw material solution is 1:1.

[0029] Then the raw material solution was drained into a polytetrafluoroethylene-lined stainless steel reactor through a glass rod, and placed in an oven for hydrothermal reaction at a hydrothermal temperature of 120°C and a hydrothermal time of 24 hours;

[0030] After the hydrothermal reaction is completed, take out the polytetrafluoroethylene-lined stainless steel reactor and cool it to normal temperature, and separate the solution from solid to liquid to obtain a catalyst ...

Embodiment

[0044]Take a beaker with a volume of 50ml, add 20ml of deionized water, add the rotor, place it on a constant temperature magnetic stirring instrument, weigh 0.0075mol of cerium nitrate through an electronic balance, add it to the beaker, and after it is fully dissolved, weigh 0.0075mol of potassium permanganate Add it into a beaker and stir at a constant speed for 0.5h at room temperature to fully dissolve the solution.

[0045] Transfer the above solution to a 50mL polytetrafluoroethylene-lined stainless steel reactor, and place the reactor in an oven at 120°C for hydrothermal reaction; after 24 hours, take out the 50mL polytetrafluoroethylene-lined stainless steel reactor in the oven, and Cool down to room temperature, open the reactor, pour the solution into a prepared beaker, perform suction filtration, take the filtered material and add it to a centrifuge tube, wash with alcohol for 3 times, wash with water for 3 times, and centrifuge at a speed of 2000r / min. The superna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com