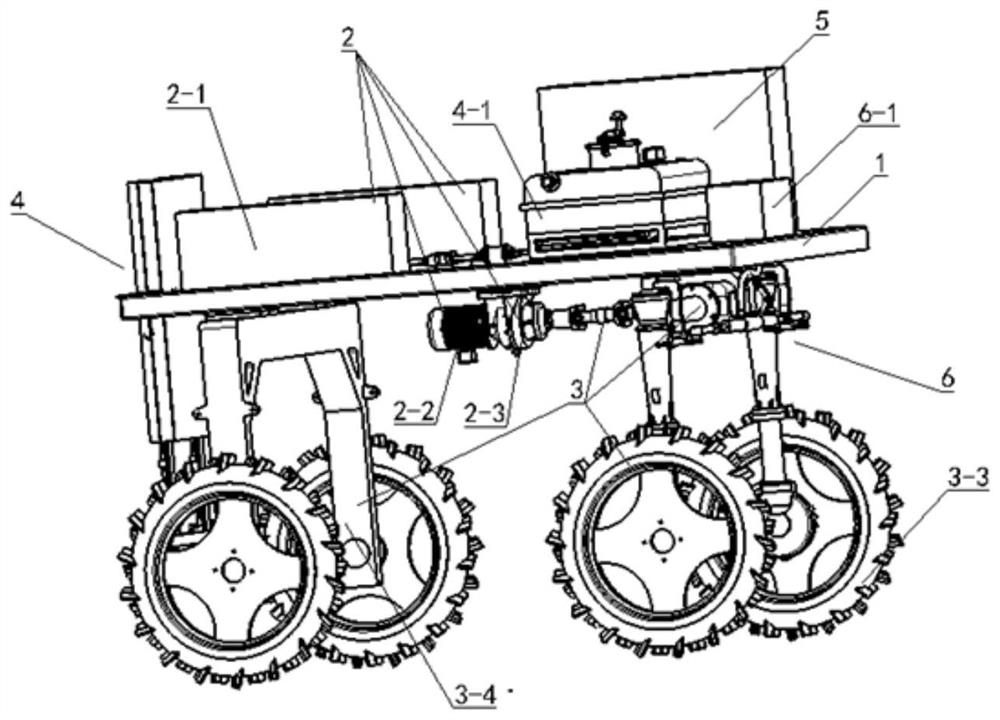

Self-propelled high-clearance pineapple flower forcing machine based on PLC control

A pineapple flower forcing machine, high ground clearance technology, applied in control devices, applications, horticulture and other directions, can solve problems such as increased cost, large planting area, waste, etc., to ensure high efficiency and accuracy, high degree of mechanization, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

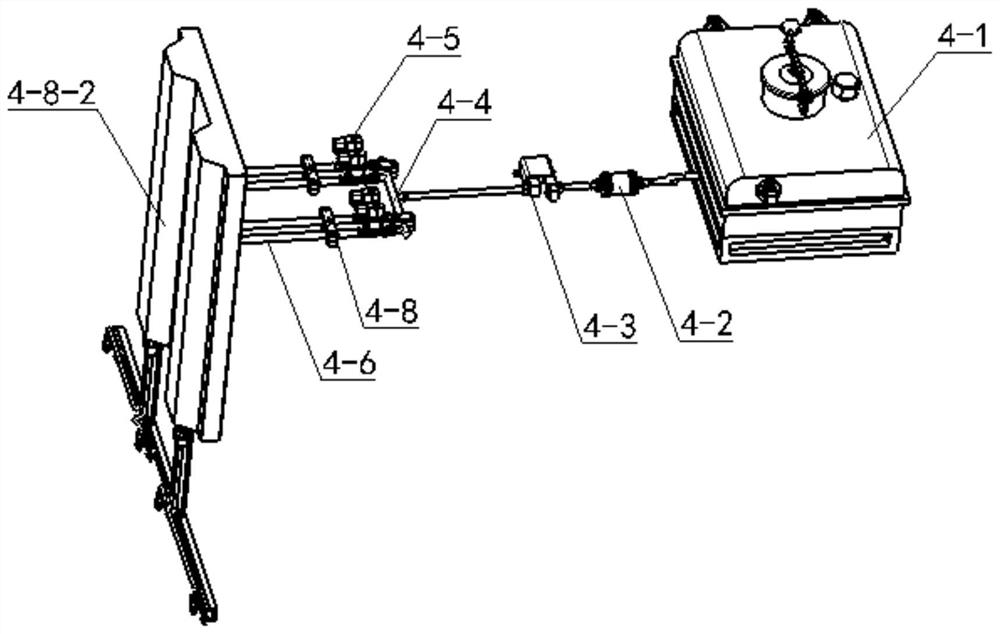

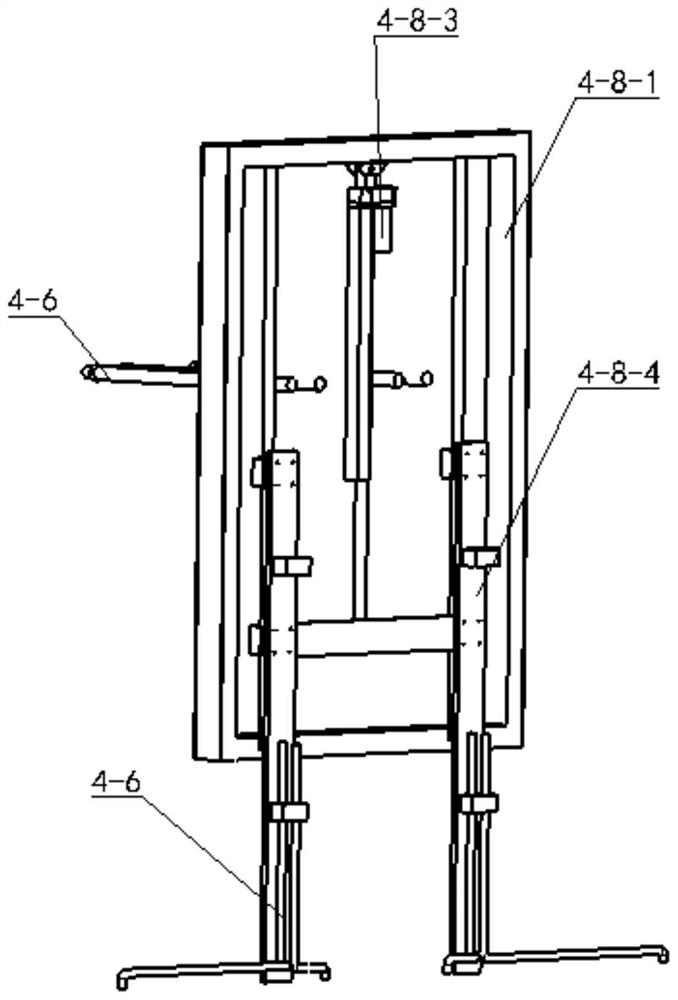

[0048] The sprinkler system 4 includes a water tank 4-1, a connecting pipe 4-6, a sprinkler 4-7 and a lifting device 4-8; the lifting device 4-8 includes a frame plate 4-8-1, a casing 4-8-2 and is arranged on Push rod motor 4-8-3, sliding plate 4-8-4 between frame plate 4-8-1 and shell 4-8-2; frame plate 4-8-1 is vertically installed on one end of frame 1 ;

[0049] The push rod motor 4-8-3 is fixed on the top of the frame plate 4-8-1; the sliding plate 4-8-4 is set in parallel with the push rod motor 4-8-3, and is connected with the push rod motor 4-8-3 , and at least two pieces are provided; the push rod motor 4-8-3 is electrically connected with the PLC control system 5;

[0050] The spraying device 4-7 includes a sliding track 4-7-1; the sliding track 4-7-1 is arranged horizontally, and is fixedly connected with the bottom end of each sliding plate 4-8-4; the sliding track 4-7-1 is equipped with at least 4 Each nozzle 4-7-2, the nozzle 4-7-2 is connected with a connectin...

Embodiment 2

[0053] Embodiment 2: The device has two control modes: manual and automatic. The manual control mode is mainly used to adjust the state of the equipment and debug the operation. In the automatic mode, the pineapple flower forcing equipment will move independently at a constant speed according to the set speed.

Embodiment 3

[0054] Embodiment 3: The bottom of the frame is prescribed to be connected with several beams, and the several beams strengthen the strength of the frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com