Manufacturing method of carbon fiber column lattice truss sandwich structure

A technology of sandwich structure and manufacturing method, which is applied in the field of sandwich structure of composite materials, can solve the problems of structural mechanical performance degradation, complex mold components, etc., and achieve the effects of easy pouring, simple manufacturing method, good geometry and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

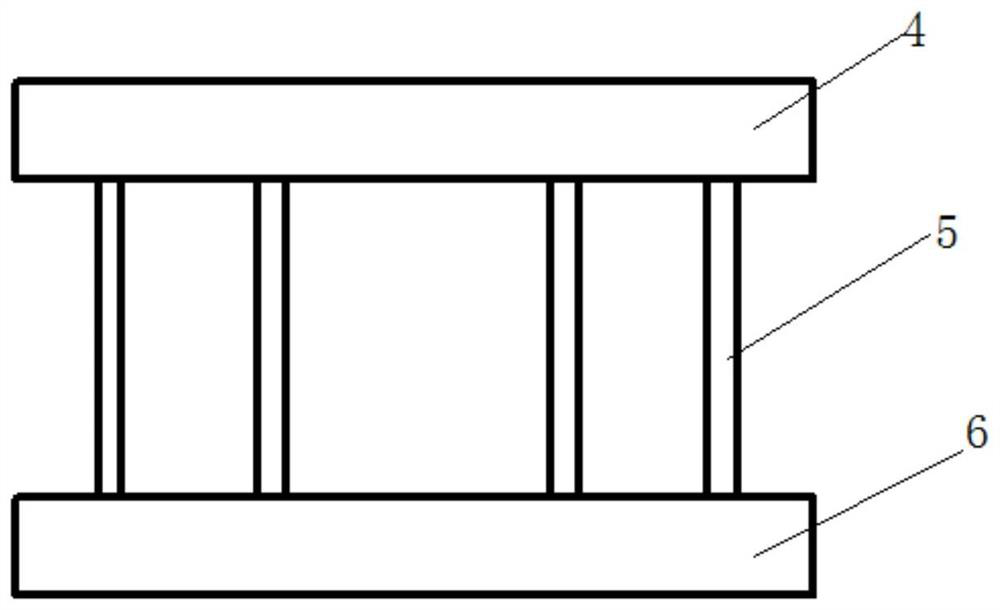

[0053] Its structure is as figure 1 As shown, the sandwich layer is a core topology composed of a vertical columnar truss core grid structure. Its preparation method is as follows:

[0054] Place the Himalayan salt block used as a sacrificial mold on a rectangular wooden pad, and process it into a 300×200×37 mm cuboid with a CNC milling machine; drill bits with diameters of 2, 3, and 4 mm are selected on the CNC machine tool for drilling operations; The centerline distance between the columns is 15 mm; the dry carbon fiber fabric prefabricated body is cut into a size larger than the salt block, covered on the upper and lower surfaces of the salt block respectively and fixed with adhesive tape; Immerse one end of the bundle in distilled water, then pull the excess water through the small holes in the rubber membrane, and stitch the continuous carbon fiber tow through the holes in the salt block from the carbon fiber fabric on one side to the carbon fiber fabric on the other si...

Embodiment 2

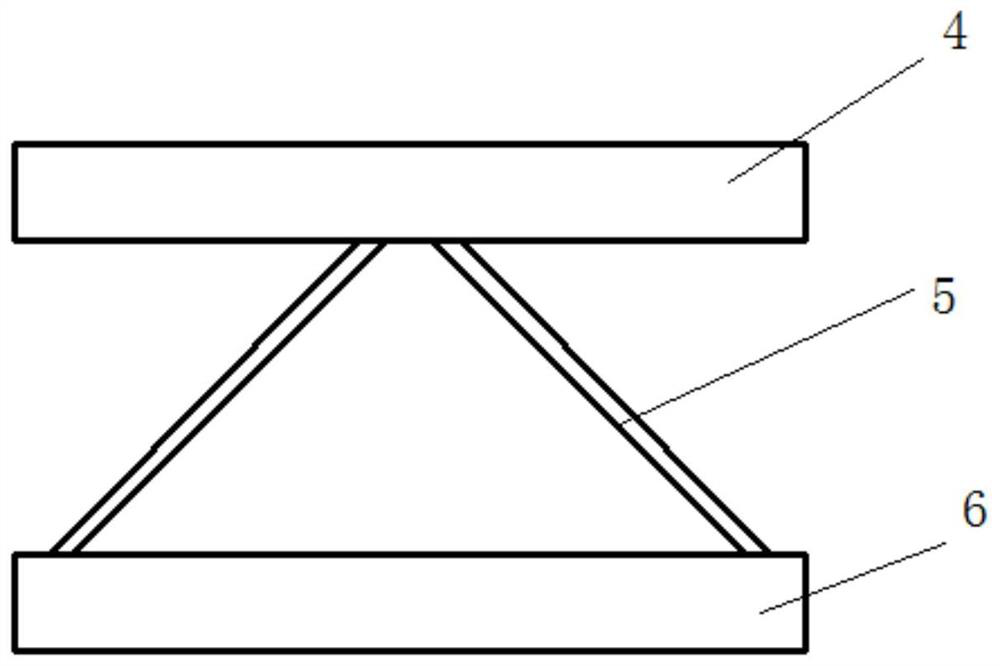

[0056] Its structure is as figure 2 As shown, the sandwich layer is a core topology composed of a pyramid grid truss core grid structure. Its preparation method is as follows:

[0057] Place the Himalayan salt block used as a sacrificial mold on a rectangular wooden pad, and process it into a 300×200×37mm cuboid with a CNC milling machine; design a jig to guide the oblique drilling operation, the jig is placed on the salt block, and then used separately 2, 3, and 4 mm drill bits are manually drilled to form a pyramid structure at 45 degrees; the dry carbon fiber fabric prefabricated body is cut into a size larger than the salt block, and the upper and lower surfaces of the salt block are respectively covered and fixed with adhesive tape; Before fiber sewing, immerse one end of the dry fiber tow in distilled water, then pull out the excess water through the small hole in the rubber membrane, and stitch the continuous carbon fiber tow through the hole of the salt block from on...

Embodiment 3

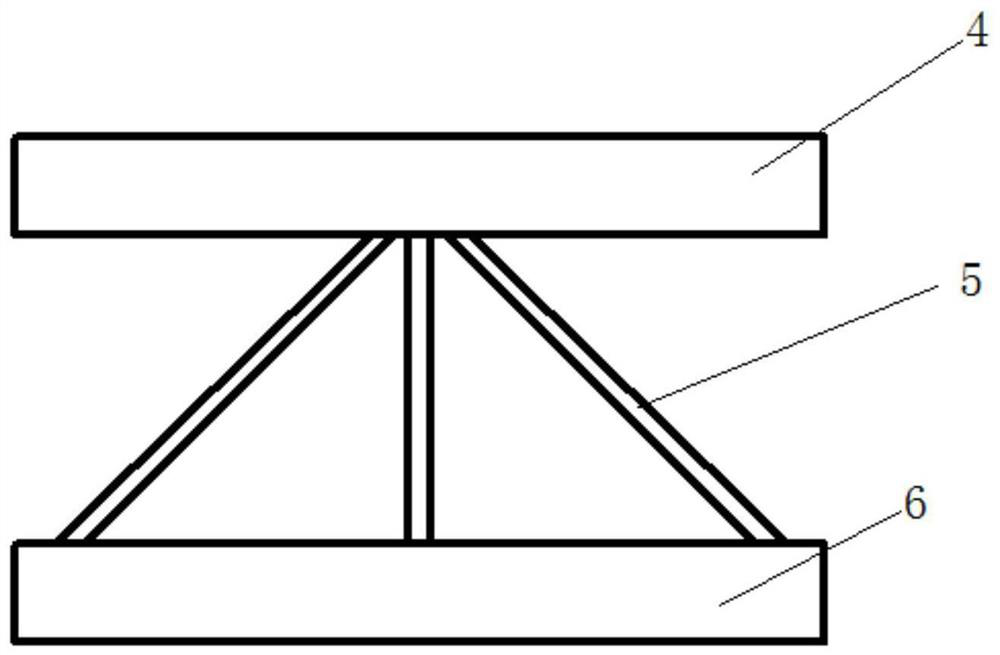

[0059] Its structure is as image 3 As shown, the sandwich layer is a core topology consisting of a pyramidal grid truss core grid containing an additional vertical column structure. Its preparation method is as follows:

[0060] Place the Himalayan salt block used as a sacrificial mold on a rectangular wooden pad, and process it into a 300×200×37 mm cuboid with a CNC milling machine; design a jig to guide the oblique drilling operation, and the jig is placed on the salt block for use 2,3 , a 4 mm drill bit is manually drilled to form a pyramid structure at 45 degrees, and then a drill bit with a diameter of 2, 3, and 4 mm is used to drill a central vertical hole; the dry carbon fiber fabric prefabricated body is cut to a size larger than the salt block, Cover the upper and lower surfaces of the salt block respectively and fix them with adhesive tape; before the fiber is stitched, one end of the dry fiber tow is immersed in distilled water, and then the excess water is pulled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com