Noctilucent cold-laid permeable asphalt and preparation method thereof

A technology of permeable asphalt and cold paving, applied in the field of building materials, can solve the problem that matrix asphalt is difficult to solve the problem of pavement fatigue life, and achieve the effects of improving variability and aesthetics, low odor concentration, and strengthening mechanical properties and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

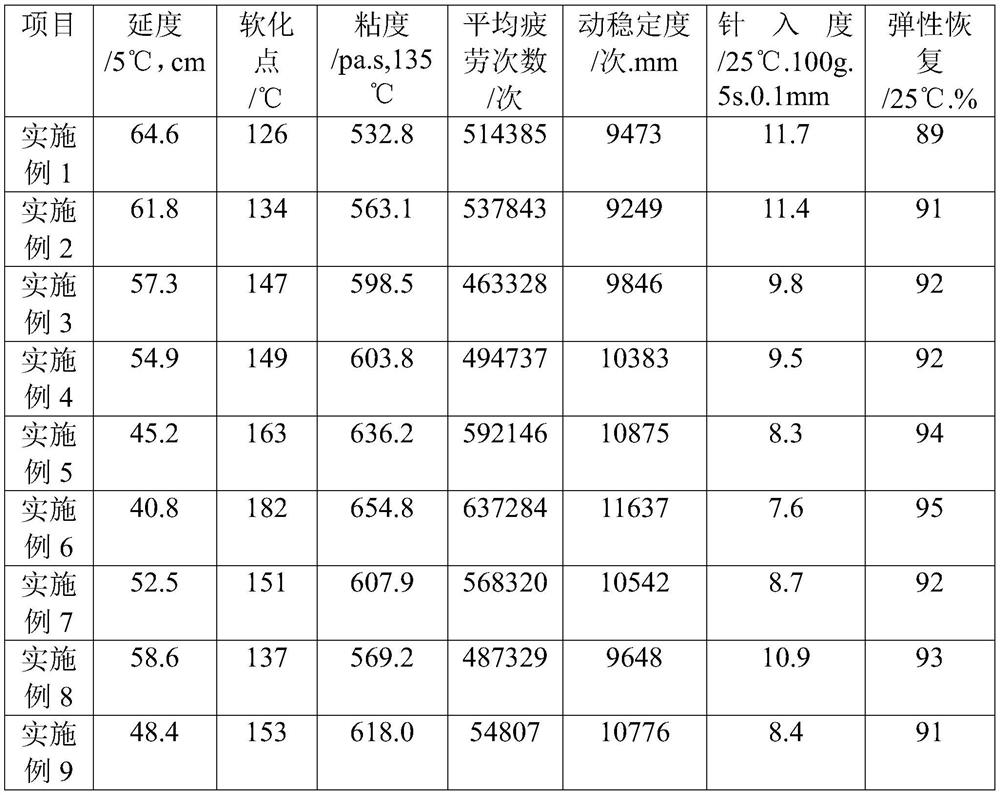

Examples

preparation example Construction

[0030] A preparation method of luminous cold-paved permeable asphalt, which is used to prepare the luminous cold-paved permeable asphalt, comprising the following steps:

[0031] 1) Material configuration: The configuration components are matrix asphalt: waste tire rubber powder: luminous material: reinforcing agent: toughening fiber: waste oil: color pigment = 45~60: 10~20: 8~15: 5~10: 3-8: 1-5: 20-30.

[0032] 2) Improve the softening point of the base asphalt: the base asphalt enters the flash tower for multiple flashes, including: one flash: the base asphalt enters the first flash tower at 250-300°C and vacuum -45-55kpa Flash evaporation removes 20-30% of the heavy components; secondary flash evaporation: the bitumen obtained from the first flash evaporation enters the second flash evaporation, and removes 5-15% of the light components. After entering the reaction kettle, the vacuum degree is controlled at -45~55kpa during air oxidation, and the air flow rate is 20~30Nm3...

Embodiment 1

[0035] Example 1: A luminous cold-paved permeable asphalt and its preparation method

[0036] Luminous cold-paved permeable asphalt includes the following components: 45g base asphalt, 11.5g waste tire rubber powder, 8g luminescent material, 5g nano-graphene, 3g Delanit fiber, 1g waste oil, 20g color pigment.

[0037] The preparation method of luminous cold-paved permeable asphalt comprises the following steps:

[0038] 1) Improve the softening point of the base asphalt: put 45g of the base asphalt into the flash tower for multiple flash evaporation, including: the base asphalt enters the flash tower once, and remove 20-30% by flash evaporation under the conditions of 250°C and vacuum degree of -45kpa The heavy components are then entered into secondary flash evaporation to remove 5-15% of the light components at 250°C and a vacuum of -45kpa. After entering the reaction kettle, the vacuum degree is controlled at -45kpa and the air flow rate is 20Nm3 / h during air oxidation to ...

Embodiment 2

[0041] Example 2: A luminous cold-paved permeable asphalt and its preparation method

[0042]Luminous cold-paved permeable asphalt includes the following components: 47g base asphalt, 10g waste tire rubber powder, 8.7g luminescent material, 6g nano-graphene, 5g basalt fiber, 1.7g waste oil, and 21g color pigment.

[0043] The preparation method of luminous cold-paved permeable asphalt comprises the following steps:

[0044] 1) Improve the softening point of the matrix asphalt: put 47g of the matrix asphalt into the flash tower for multiple flash evaporation, including: the matrix asphalt enters the flash tower once, and remove 20-30% by flash evaporation under the conditions of 255°C and vacuum degree of -46kpa The heavy components are then entered into secondary flash evaporation to remove 5-15% of the light components at 250°C and a vacuum of -45kpa. After entering the reaction kettle, the vacuum degree is controlled at -46kpa and the air flow rate is 22Nm3 / h during air oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com