Method for preparing foamed ceramic thermal insulation material with low energy consumption by using fluorocarbon cerium type rare earth tailings and product

A technology of rare earth tailings and foamed ceramics, applied in the production of ceramic materials, clay products, ceramic products, etc., can solve the problems of environmental pollution, large land occupation, etc., and achieve the effects of reducing production costs, reducing energy consumption, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

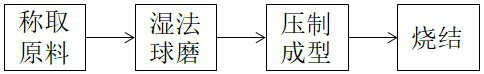

Image

Examples

Embodiment 1

[0040] The process of preparing the foamed ceramic insulation material in this embodiment is as follows.

[0041] (1) Weigh raw materials

[0042] The components were weighed according to the following mass percentages: bastnaesic rare earth tailings 60wt%, kaolin 25wt%, quartz 14wt%, foaming agent 1wt%. In this embodiment, the foaming agent is silicon carbide. Mix the weighed components uniformly to obtain the first intermediate.

[0043] (2) Wet ball milling

[0044] After adding 50wt% water of the first intermediate to the first intermediate, put it into a ball mill for wet ball milling to obtain a uniformly mixed slurry. It is required that the particle size of each component in the slurry is less than 200 mesh.

[0045] (3) Compression molding

[0046] Dry the ball-milled slurry in step 2 at a temperature of 130° C. for 80 minutes to obtain raw meal. After the dried raw material is pressed into shape, a foamed ceramic green body is obtained.

[0047] (4) Sintering ...

Embodiment 2

[0050] The process of preparing the foamed ceramic insulation material in this embodiment is as follows.

[0051] (1) Weigh raw materials

[0052] The components were weighed according to the following mass percentages: bastnaesic rare earth tailings 65wt%, kaolin 25wt%, quartz 9wt%, foaming agent 1wt%. In this embodiment, the foaming agent is manganese dioxide. Mix the weighed components uniformly to obtain the first intermediate.

[0053] (2) Wet ball milling

[0054] After adding 50wt% water of the first intermediate to the first intermediate, put it into a ball mill for wet ball milling to obtain a uniformly mixed slurry. It is required that the particle size of each component in the slurry is less than 200 mesh.

[0055] (3) Compression molding

[0056] Dry the ball-milled slurry in step 2 at a temperature of 100° C. for 120 minutes to obtain raw meal. After the dried raw material is pressed into shape, a foamed ceramic green body is obtained.

[0057] (4) Sintering...

Embodiment 3

[0060] The process of preparing the foamed ceramic insulation material in this embodiment is as follows.

[0061] (1) Weigh raw materials

[0062] Each component was weighed according to the following mass percentages: bastnaesic rare earth tailings 70wt%, kaolin 23wt%, quartz 5wt%, foaming agent 2wt%. In this embodiment, the foaming agent is manganese dioxide. Mix the weighed components uniformly to obtain the first intermediate.

[0063] (2) Wet ball milling

[0064] After adding 50wt% water of the first intermediate to the first intermediate, put it into a ball mill for wet ball milling to obtain a uniformly mixed slurry. It is required that the particle size of each component in the slurry is less than 200 mesh.

[0065] (3) Compression molding

[0066] Dry the ball-milled slurry in step 2 at a temperature of 110° C. for 80 minutes to obtain uniformly mixed raw meal. After the dried raw material is pressed into shape, a foamed ceramic green body is obtained.

[0067]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com