Low-temperature-resistant leather ink and preparation method thereof

A technology of low temperature resistance and ink, which is applied in leather surface treatment, small raw leather/big raw leather/leather/fur treatment, small raw leather/big raw leather/leather skin/fur chemical treatment, etc., and can solve the problem of ink weatherability that cannot withstand low temperature conditions The test, cumbersome process, and various raw materials have achieved the effect of excellent low temperature resistance, convenient process, and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

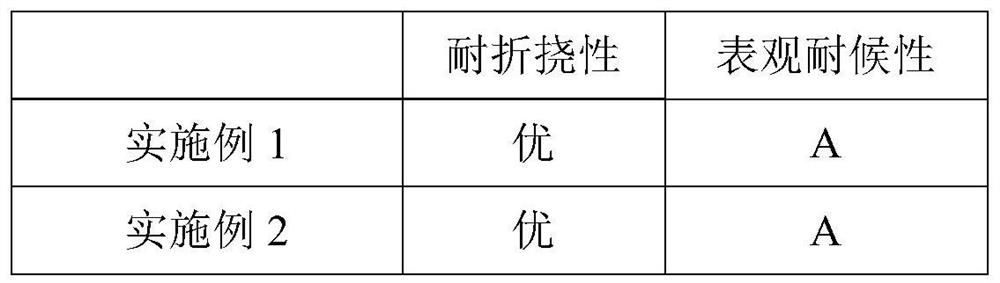

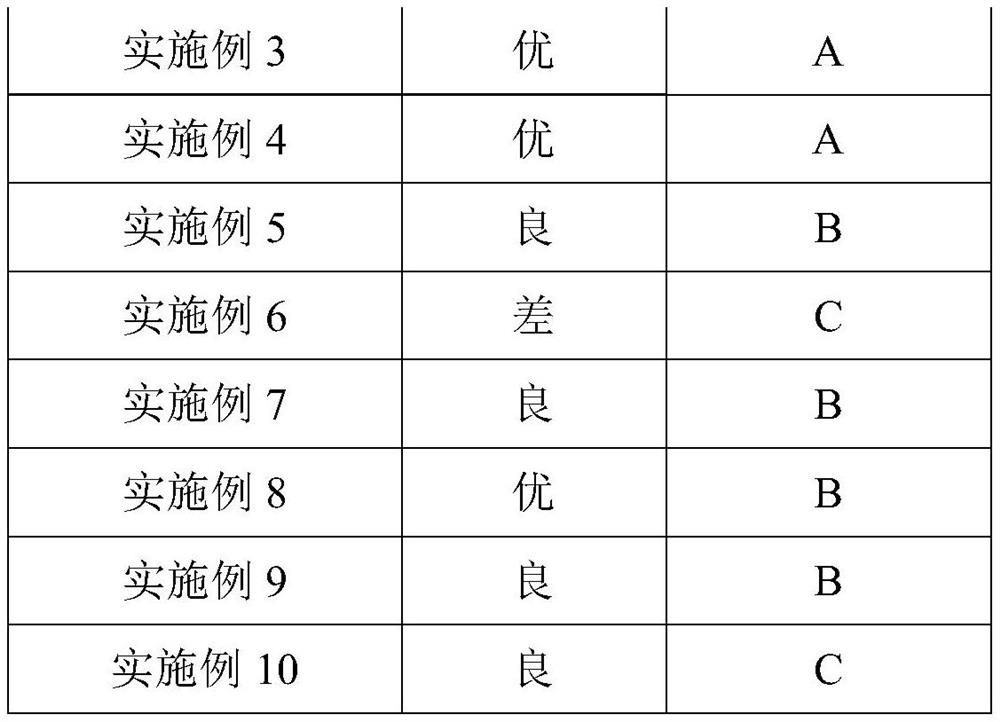

Examples

Embodiment 1

[0046] This embodiment provides a low-temperature leather ink, according to weight percent, its raw material includes 76% acrylate, 5% pyrrolidone, 4% photoinitiator, 0.5% of the leveling agent, 0.3% dispersant, coupling 0.5% of the agent, an antioxidant 0.3%, and the slurry replenishing margin.

[0047] The acrylate is an isothersteric, tetrahydrofuranacrylate, and polyethylene glycol 600 diacrylate.

[0048] The weight ratio of lysate of acrylate, tetrahydrofuranacrylate, and polyethylene glycol 600 diacrylate is 3.6: 12.5: 2.5.

[0049] The pyrrolidone is a vinylpyrrolidone, and the unsaturation of vinylpyrrolidone is 3, and the CAS number is 88-12-0.

[0050] The photoinitiator is 2,4,6-trimethylbenzoyl-diphenyl phosphine, CAS number 75980-60-8.

[0051] The level of the leveling agent is BYK-333. [Not retrieved to BASF 333, please check if BASF 3033 or byk (Bik) 333; if it is determined to be BASF 333, please provide a purchase manufacturer】

[0052] The amine value of the di...

Embodiment 2

[0058] This example provides a low-temperature leather ink, according to weight percent, its raw material includes 78% acrylate, 6% pyrrolidone, 4% photoinitiator, 0.6%, dispersant 0.3%, coupling 0.5% of the agent, an antioxidant 0.3%, and the slurry replenishing margin.

[0059] The acrylate is an isothersteric, tetrahydrofuranacrylate, and polyethylene glycol 600 diacrylate.

[0060] The weight ratio of lysate of acrylate, tetrahydrofuranacrylate, and polyethylene glycol 600 diacrylate is 3.6: 12.5: 2.5.

[0061] The pyrrolidone is a vinylpyrrolidone, and the unsaturation of vinylpyrrolidone is 3, and the CAS number is 88-12-0.

[0062] The photoinitiator is 2,4,6-trimethylbenzoyl-diphenyl phosphine, CAS number 75980-60-8.

[0063] The level of the leveling agent is BYK-333.

[0064] The amine value of the dispersant is 17 mg kOH / g, purchases from Shanghai Guangye Chemical Co., Ltd., model is the UK Ka Card Uniqchem Uniqjet9510.

[0065] The antioxidant is a terzphenol, and th...

Embodiment 3

[0070] This example provides a low-temperature leather ink, according to the weight percentage, the raw material includes 72% acrylate, 4% pyrrolidone, 4% photoinitiator, 0.3% of the leveling agent, 0.3% dispersant, coupling 0.5% of the agent, an antioxidant 0.3%, and the slurry replenishing margin.

[0071] The acrylate is an isothersteric, tetrahydrofuranacrylate, and polyethylene glycol 600 diacrylate.

[0072] The weight ratio of lysate of acrylate, tetrahydrofuranacrylate, and polyethylene glycol 600 diacrylate is 3.6: 12.5: 2.5.

[0073] The pyrrolidone is a vinylpyrrolidone, and the unsaturation of vinylpyrrolidone is 3, and the CAS number is 88-12-0.

[0074] The photoinitiator is 2,4,6-trimethylbenzoyl-diphenyl phosphine, CAS number 75980-60-8.

[0075] The level of the leveling agent is BYK-333.

[0076] The amine value of the dispersant is 17 mg kOH / g, purchases from Shanghai Guangye Chemical Co., Ltd., model is the UK Ka Card Uniqchem Uniqjet9510.

[0077] The antiox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com