Preparation method of bimetallic organic framework derived magnetic carbon composite wave-absorbing material

A technology of composite absorbing materials and organic frameworks, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of easy regulation of absorption performance, high absorption intensity, and optimized impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

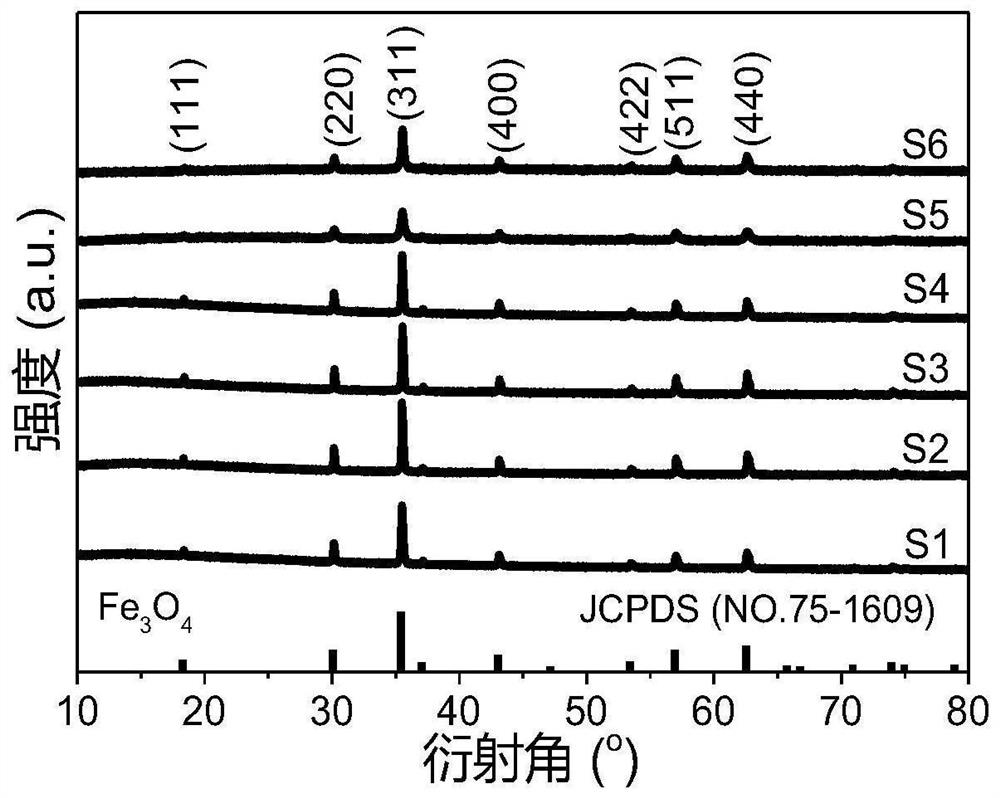

Examples

Embodiment 1

[0045] (1) Take a 150mL beaker, add 80mL DMF, add 80mg graphite oxide while stirring, and stir for 0.5h after ultrasonication for 1.5h to make a GO dispersion with a concentration of 1mg / mL;

[0046] (2) Add 1.989g FeCl to the GO dispersion obtained above 3 ·6H 2 O stir vigorously until completely dissolved;

[0047] (3) Add 1.2227g H to the mixed dispersion obtained above 2 BDC was stirred vigorously until it was completely dissolved, and finally stirred vigorously for 0.5h;

[0048] (4) Transfer the mixed dispersion liquid to a polytetrafluoroethylene-lined autoclave with a volume of 100 mL, and conduct a solvothermal reaction at 110° C. for 24 h;

[0049] (5) After the reaction is finished, cool to room temperature, repeatedly use DMF and absolute ethanol to centrifuge and wash several times, and collect the precipitate;

[0050] (6) The precipitate after washing is transferred to a vacuum freeze dryer, and dried for 24 hours to constant weight;

[0051](7) Perform hig...

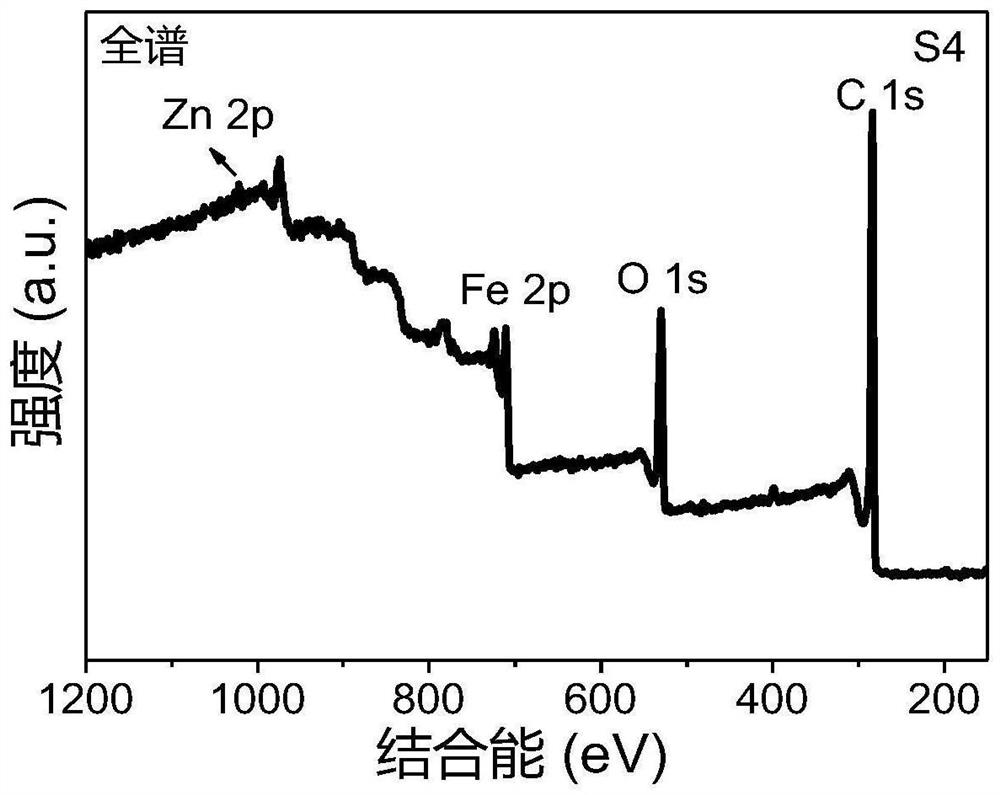

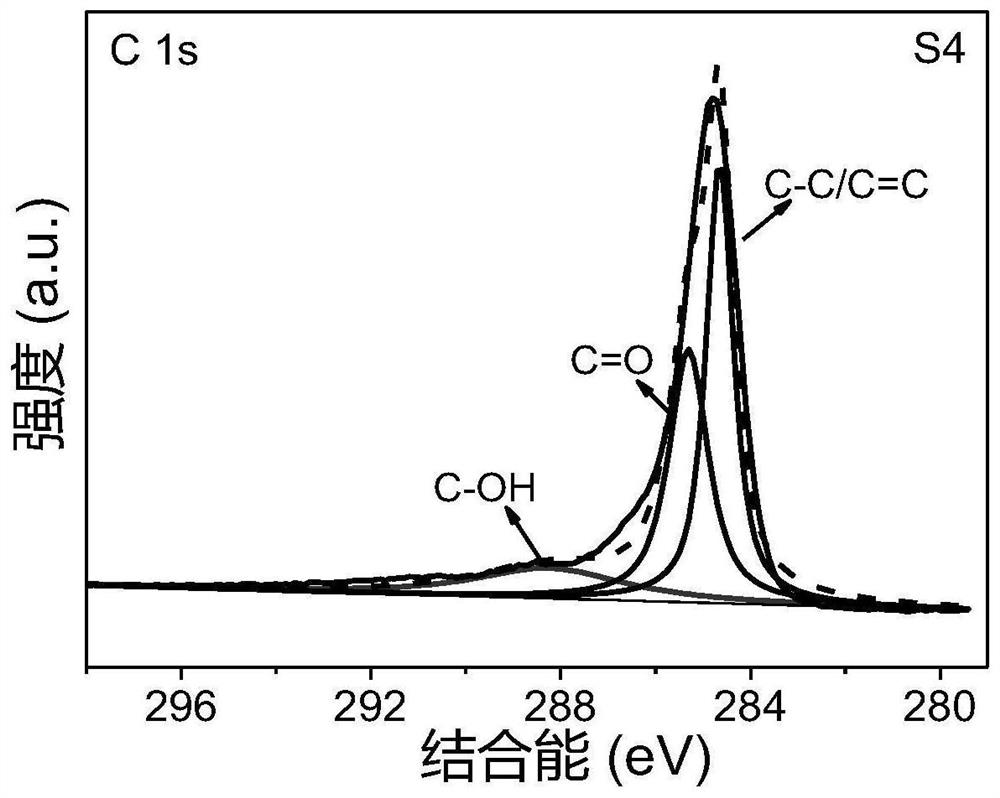

Embodiment 2

[0054] (1) Take a 150mL beaker, add 80mL DMF, add 80mg graphite oxide while stirring, and stir for 0.5h after ultrasonication for 1.5h to make a GO dispersion with a concentration of 1mg / mL;

[0055] (2) Add 1.3271g FeCl to the GO dispersion obtained above 3 ·6H 2 O and 0.3339g ZnCl 2 Stir vigorously until completely dissolved;

[0056] (3) Add 1.2227g H to the mixed dispersion obtained above 2 BDC was stirred vigorously until it was completely dissolved, and finally stirred vigorously for 0.5h;

[0057] (4) Transfer the mixed dispersion liquid to a polytetrafluoroethylene-lined autoclave with a volume of 100 mL, and conduct a solvothermal reaction at 110° C. for 24 h;

[0058] (5) After the reaction is finished, cool to room temperature, repeatedly use DMF and absolute ethanol to centrifuge and wash several times, and collect the precipitate;

[0059] (6) The precipitate after washing is transferred to a vacuum freeze dryer, and dried for 24 hours to constant weight;

...

Embodiment 3

[0063] (1) Take a 150mL beaker, add 80mL DMF, add 80mg graphite oxide while stirring, and stir for 0.5h after ultrasonication for 1.5h to make a GO dispersion with a concentration of 1mg / mL;

[0064] (2) Add 0.9947g FeCl to the GO dispersion obtained above 3 ·6H 2 O and 0.5016g ZnCl 2 Stir vigorously until completely dissolved;

[0065] (3) Add 1.2227g H to the mixed dispersion obtained above 2 BDC was stirred vigorously until it was completely dissolved, and finally stirred vigorously for 0.5h;

[0066] (4) Transfer the mixed dispersion liquid to a polytetrafluoroethylene-lined autoclave with a volume of 100 mL, and conduct a solvothermal reaction at 110° C. for 24 h;

[0067] (5) After the reaction is finished, cool to room temperature, repeatedly use DMF and absolute ethanol to centrifuge and wash several times, and collect the precipitate;

[0068] (6) The precipitate after washing is transferred to a vacuum freeze dryer, and dried for 24 hours to constant weight;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com