A method for preparing diamond-reinforced metal matrix composites with high surface precision and high reliability

A diamond reinforced and composite material technology is applied in the field of metal matrix composite materials and its preparation, which can solve the problems of low surface precision and poor reliability, and achieve the effects of high surface precision and thermal conductivity, improved thermal conductivity and simple process method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

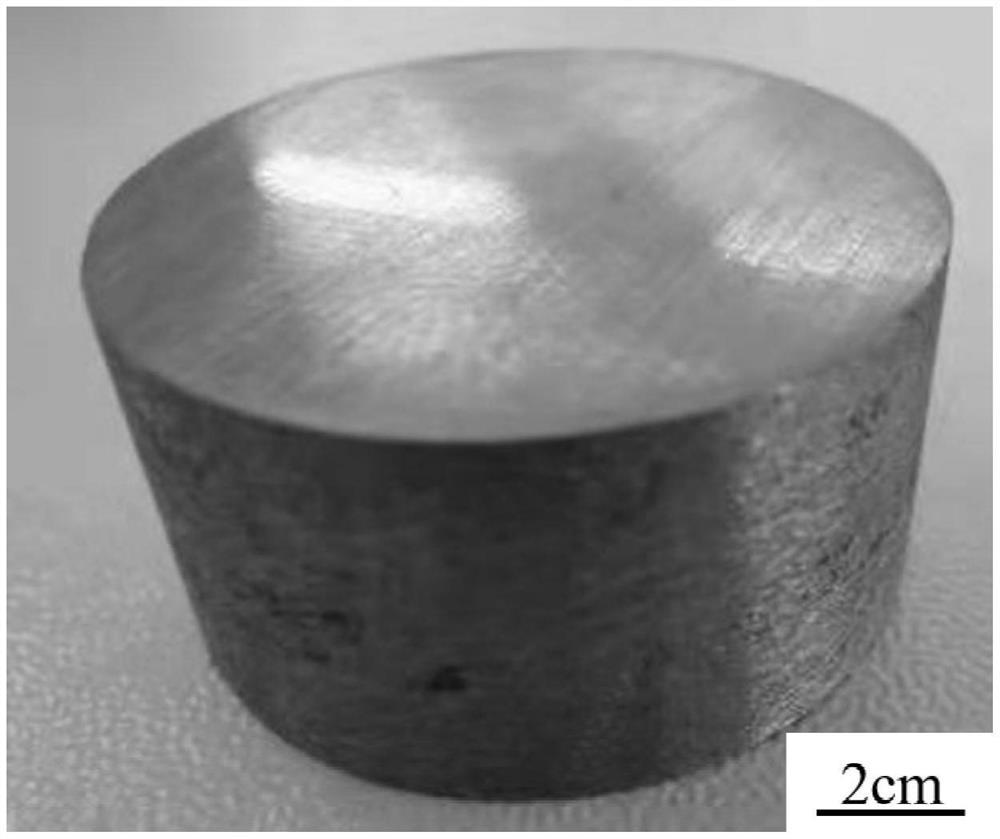

Image

Examples

specific Embodiment approach 1

[0021] Specific implementation mode 1: The preparation method of diamond-reinforced metal matrix composite material with high surface precision and high reliability in this implementation mode is carried out according to the following steps:

[0022] 1. Weighing: Weigh 5% to 8% of diamond powder with an average particle size of 5 to 20 μm, 45% to 72% of diamond powder with an average particle size of 20 to 300 μm, and the rest of the metal matrix by volume fraction;

[0023] The diamond powder with an average particle size of 5-20 μm and the diamond powder with an average particle size of 20-300 μm have a coating on the surface; the coating material is W, Mo, Cr, Ti, etc.;

[0024] W, Mo, Cr, and Ti are easy to react with diamond at high temperature to form carbides, and the formed carbides are stable, and will not cause significant changes in thermal conductivity after wet heat treatment.

[0025] 2. Preparation of diamond preform:

[0026] Take 50% of the diamond powder wit...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that: the metal substrate in Step 1 is pure aluminum, aluminum alloy, pure copper or copper alloy.

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the aluminum alloy is Al-Si alloy, Al-Si-Cu alloy, Al-Cu-Mg alloy, Al-Zn-Cu alloy, Al- One or a combination of Zn-Mg-Cu alloys, Al-Si-Cu-Mg alloys; the copper alloy is one or several of Cu-Zn, Cu-Sn, Cu-Ni alloys combination of species.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com