Q550MD low-alloy high-strength steel plate and production method thereof

A high-strength steel plate and production method technology, applied in the direction of process efficiency improvement, furnace type, furnace, etc., can solve the problems of low plate shape qualification rate and yield rate, increased alloy cost, short production process, etc., to achieve guaranteed performance and plate Shape, reduce alloy cost, improve plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

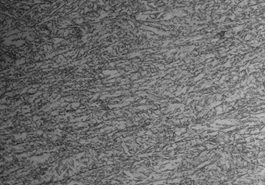

[0046] To produce Q550MD low-alloy high-strength steel plates with a thickness specification of 20mm, smelting molten steel with the following mass percentage chemical composition: C: 0.07wt%, Si: 0.10wt%, Mn: 1.60wt%, P: 0.013wt%, S: 0.005 wt%, Nb: 0.03wt%, Ti: 0.010wt%, B: 0.0012wt%, Als: 0.02wt%, the rest is Fe; the carbon equivalent is 0.34; the steel plate is LF-refined for 22 minutes by adding ferro-titanium for titanium microalloying Ferro-boron is added during soft blowing for 2 minutes to carry out boron micro-alloying. The total refining time of LF is 35 minutes, and the sum of inclusion levels is 0.5; the thickness of continuous casting slabs is 220mm, and the slabs are stacked and slowly cooled for 24 hours before being reheated in the furnace. After the slab is heated, the surface temperature is 1210°C, and the total heating time is 240 minutes; two-stage controlled rolling is adopted, the thickness to be warmed is 60mm, the final rolling temperature is 790°C, and ...

Embodiment 2

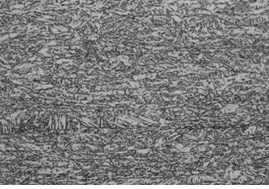

[0048] To produce Q550MD low-alloy high-strength steel plate with a thickness specification of 20mm, smelting molten steel with the following mass percentage chemical composition: C: 0.09wt%, Si: 0.20wt%, Mn: 1.70wt%, P: 0.009wt%, S: 0.003 wt%, Nb: 0.04wt%, Ti: 0.025wt%, B: 0.0016wt%, Als: 0.04wt%, and the rest is Fe. The carbon equivalent is 0.37. Ferro-titanium was added to the steel plate during LF refining for 24 minutes to carry out micro-alloying of titanium, and ferro-boron was added during soft blowing for 2.5 minutes to carry out micro-alloying of boron. The total refining time of LF was 40 minutes, and the sum of inclusion grades was 0.5; The thickness of the slab is 260mm, and the slabs are stacked and slowly cooled for 27 hours and reheated in the furnace. 840°C, the steel throwing speed of the last pass is 3.2m / s; the steel plate is cooled by DQ+air cooling+ACC three-stage cooling, the starting cooling temperature of the DQ section is 820°C, the cooling rate is 1...

Embodiment 3

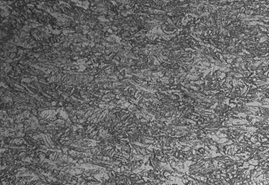

[0050] To produce Q550MD low-alloy high-strength steel plates with a thickness specification of 25mm, and to smelt molten steel with the following mass percentage chemical composition: C: 0.08wt%, Si: 0.15wt%, Mn: 1.65wt%, P: 0.01wt%, S: 0.003 wt%, Nb: 0.035wt%, Ti: 0.015wt%, B: 0.0013wt%, Als: 0.028wt%, and the rest is Fe. The carbon equivalent is 0.355. Ferro-titanium was added to the steel plate during LF refining for 23 minutes to carry out micro-alloying of titanium, and ferro-boron was added during soft blowing for 2.5 minutes to carry out micro-alloying of boron. The total refining time of LF was 42 minutes, and the sum of inclusion grades was 0.5; The thickness of the slab is 260mm, and the slabs are stacked and slowly cooled for 26 hours and reheated in the furnace. 790°C, the steel throwing speed of the last pass is 3.0m / s; the steel plate is cooled by DQ+air cooling+ACC three-stage cooling, the starting cooling temperature of the DQ section is 766°C, the cooling sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com