Composite heat preservation outer wall system and construction method

A composite thermal insulation and exterior wall technology, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems that the waterproof layer cannot meet the moisture-proof requirements of rock wool boards, the tensile strength of rock wool boards is low, and the rock wool boards are damaged by moisture. Achieve the effect of improving convenience, improving energy saving, and reducing wind and rain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

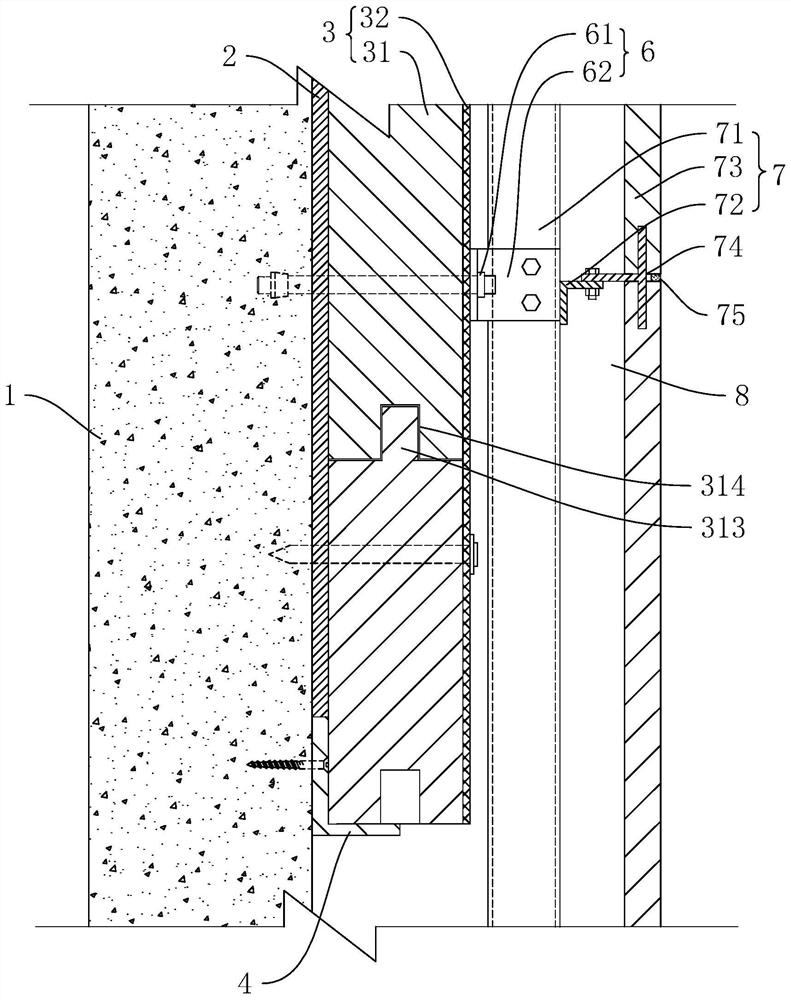

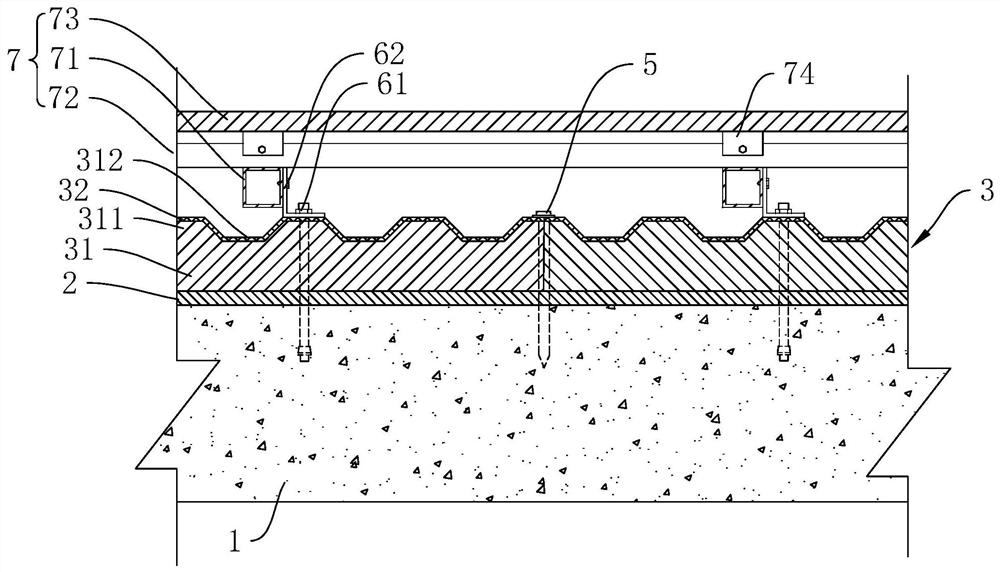

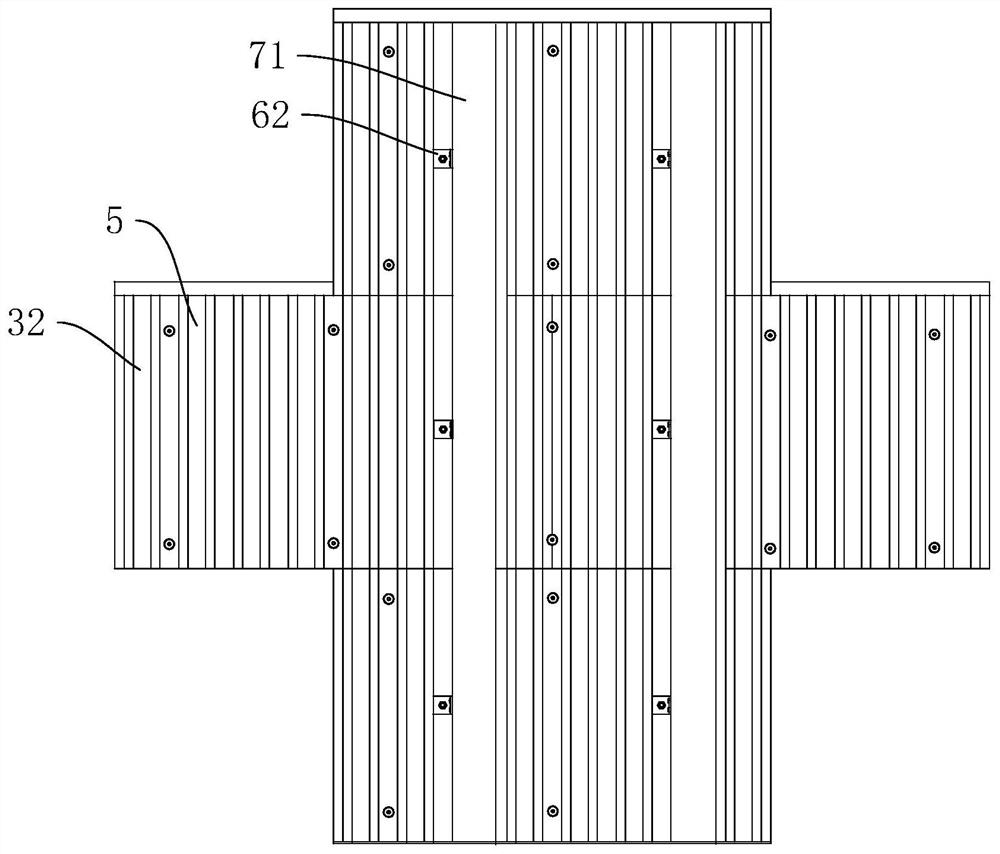

[0035] The following is attached Figure 1-3 The application is described in further detail.

[0036] In the first aspect, the embodiment of the present application discloses a composite thermal insulation exterior wall system.

[0037] refer to figure 1 , the exterior wall system includes a building wall 1, and the outer side of the building wall 1 is provided with a thermal insulation structure 3, a connecting component 6 and a curtain wall structure 7 in sequence from the inside to the outside. The thermal insulation structure 3 is used to improve the thermal insulation performance of the building wall 1, and the connecting component 6 is used to connect the thermal insulation structure 3 and the curtain wall structure 7, and the curtain wall structure 7 is used to protect the thermal insulation structure 3.

[0038] Among them, the outside of the building wall 1 is coated with polymer mortar 2, and the polymer mortar 2 is 1:3 waterproof and anti-cracking mortar with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com