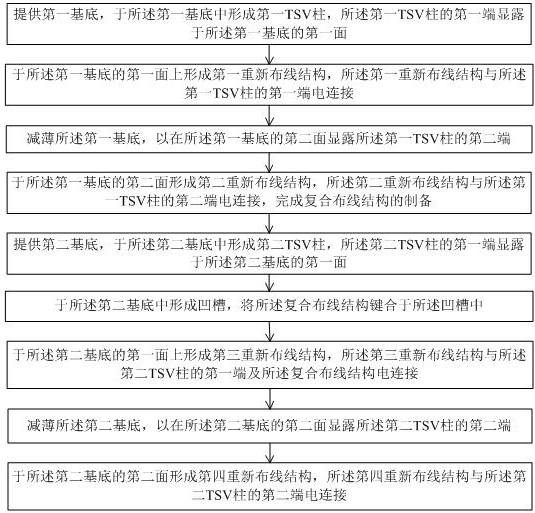

Adapter plate and preparation method thereof

An adapter board and electrical connection technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of inability to reduce the number of layers, delamination of wiring layers, and challenging wiring. Achieve the effect of facilitating circuit connection, reducing production time, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

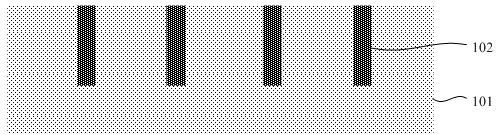

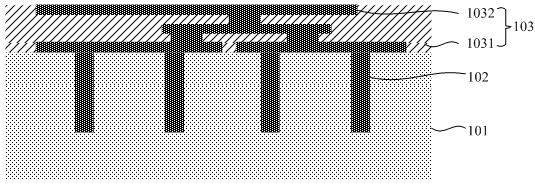

[0070] refer to Figure 2~Figure 12 , this embodiment provides an adapter board, the adapter board includes:

[0071] Composite wiring structure 100, said composite wiring structure 100 includes:

[0072] A first base 101, wherein the first base 101 has a first TSV column 102, and the first TSV column 102 runs through the first base 101;

[0073] A first rewiring structure 103, the first rewiring structure 103 is located on the first surface of the first substrate 101, and is electrically connected to the first end of the first TSV column 102;

[0074] A second rewiring structure 104, the second rewiring structure 104 is located on the second surface of the first substrate 101, and is electrically connected to the second end of the first TSV column 102;

[0075] The adapter board also includes:

[0076] The second substrate 201, the second substrate 201 has a second TSV column 202 and a groove 203, the second TSV column 202 penetrates the second substrate 201, and the compo...

Embodiment 2

[0115] refer to Figure 14~Figure 19 , this embodiment also provides an adapter board, the difference between the adapter board and the adapter board in Embodiment 1 is that the second base 301 further includes a third TSV column 303, wherein the groove 305 exposes the first end of the third TSV column 303, the second surface of the second substrate 301 exposes the second end of the third TSV column 303, and the third TSV column 303 is respectively combined with the The wiring structure 100 and the fourth rewiring structure 304 are electrically connected, so that in this embodiment, compared with the first embodiment, the double-sided electrical extraction of the composite wiring structure 100 can be further realized through the third TSV column 303 , so that the transmission path can be reduced, the transmission efficiency can be improved, and the loss can be reduced.

[0116] For the structure of the adapter plate, please refer to Embodiment 1, which will not be introduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com