Electroless nickel plating solution

An electroless nickel and solution technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as high resistance, reduced conductivity, and non-conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

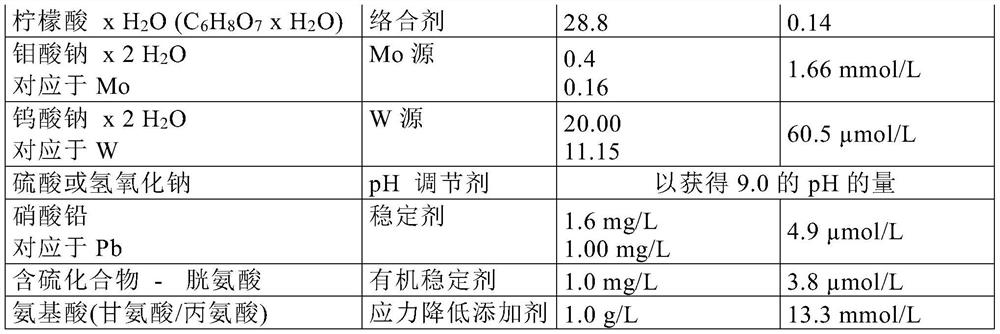

[0040] The electroless nickel plating solution of the present invention is also referred to as an electroless nickel bath or an electroless nickel plating bath. The term solution does not exclude that one or more components may be present partly in an undissolved state.

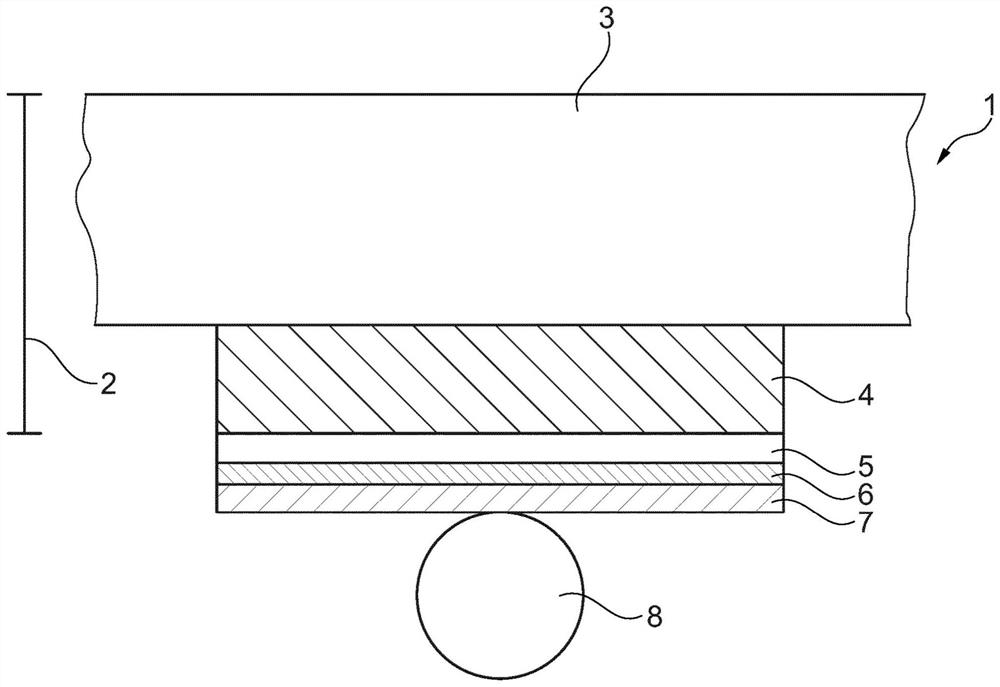

[0041] Nickel alloy layers are also referred to as quaternary nickel layers or quaternary nickel deposits, the quaternary layers comprising nickel, molybdenum, tungsten and phosphorus.

[0042] If in this description a layer is named after a metal, such as "Pd layer" or "Au layer", this term also covers alloys comprising the respective metal as a main component, if not mentioned otherwise. A major component means that the component constitutes at least 50% by weight.

[0043] When the term "comprising" is used in the present description and claims, it does not exclude other elements. For the purposes of the present invention, the term "consisting of" is considered to be a preferred embodiment of the term "c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com