Method for deburring and polishing precision part through low-pressure beam spraying

A technology for precision parts and deburring, which is applied in the field of machining of precision parts to achieve the effect of improving roughness and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

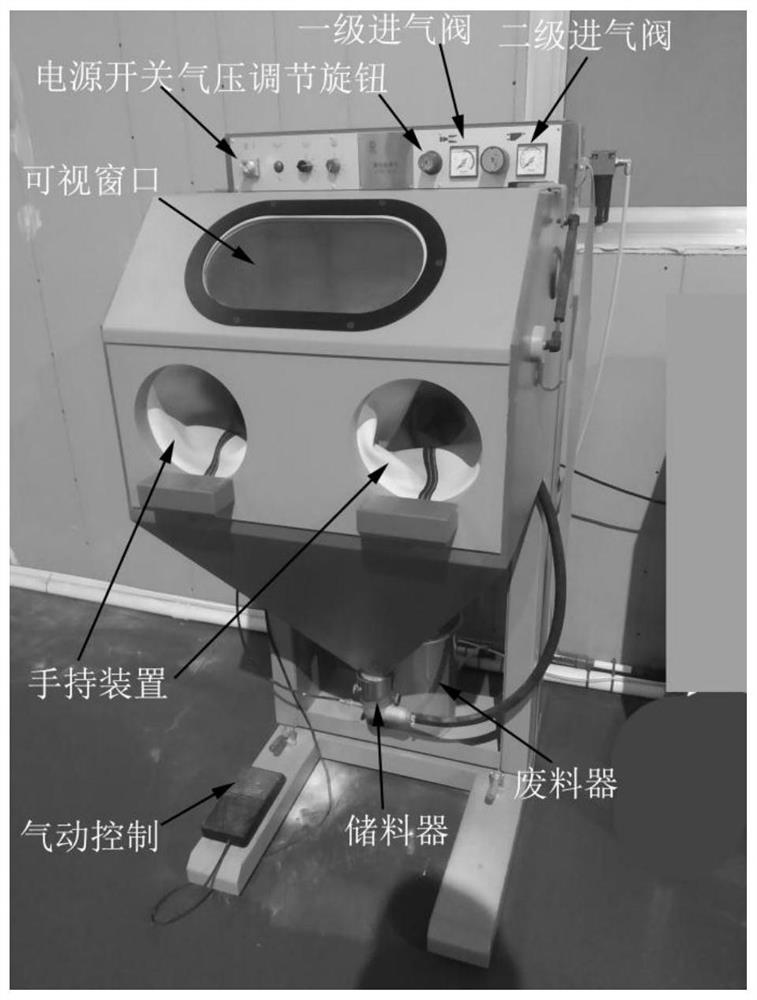

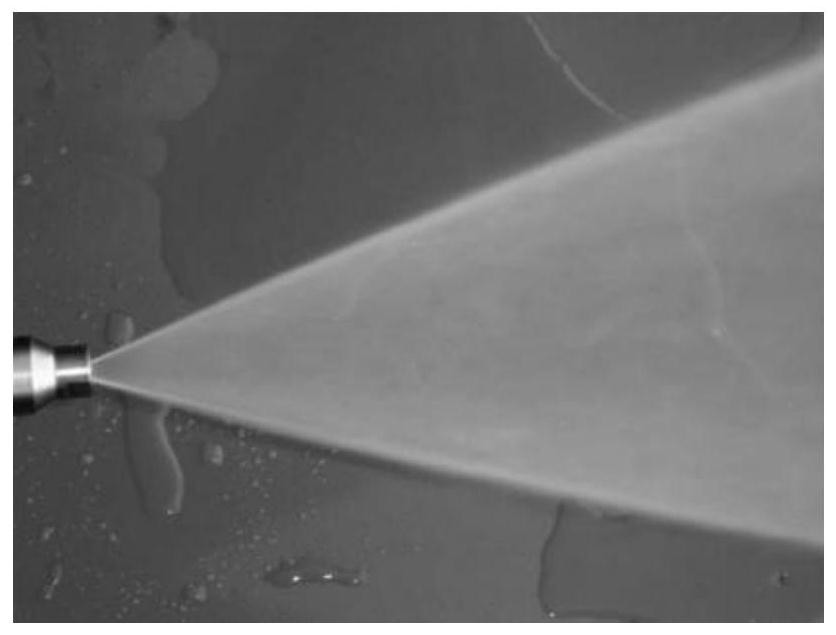

Method used

Image

Examples

Embodiment 1

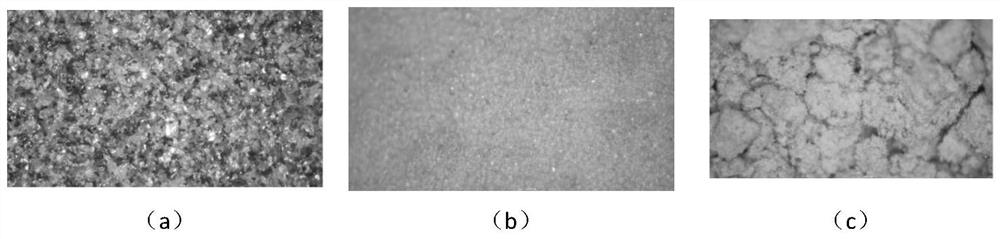

[0046] For precision bolts, surface burrs are removed, and the surface roughness Ra reaches below 3.2μm.

[0047] The method for deburring and polishing precision parts using low-pressure jets described in this embodiment includes the following steps: first, evaluate the size of the burrs on the original surface of the precision parts to be within 1-10 mm, and pick out the burrs within 1-10 mm by means of tweezers, etc. Make the burrs ≤ 1mm; secondly, select A abrasive grains according to the burr size and adjust the spray pressure to 0.2~0.3MPa; finally, use A abrasive grains and spray pressure to remove the burrs on the surface of precision parts at one time to achieve the surface roughness of precision parts Ra is 1.2 ~ 1.6μm processing requirements, to meet the requirements of 3.2μm or less. See Figure 5 , After the bolt is finished, not only the surface burr is removed, but also the surface roughness meets the requirements.

[0048] In this embodiment, the mass ratio o...

Embodiment 2

[0052] Stainless steel mesh screen, remove the burr on the surface hole to achieve a smooth transition, and its surface roughness Ra must reach 1.0μm.

[0053] The method for deburring and polishing a precision part by using a low-pressure spray jet described in this embodiment includes the following steps: first, evaluate the size of the burr on the original surface of the precision part to be 0.05-0.1 mm. Secondly, select B abrasive grains and adjust the spray pressure to 0.05-0.2MPa. Finally, use B abrasive grains and spray pressure to remove the burrs on the surface of precision parts twice to achieve a surface roughness Ra of 0.8-1.0μm. Processing requirements, there is a thin oxide scale. See Figure 6 , Before finishing, there are many burrs on the edge of the hole on the surface of the stainless steel mesh screen. In order to achieve a circular arc transition, the burr on the edge of the hole is removed after finishing, and the surface roughness meets the requirement ...

Embodiment 3

[0058] For radar antennas, the surface needs to be free of burrs, and the surface roughness Ra needs to be below 0.8 μm.

[0059] The method for deburring and polishing a precision part by using a low-pressure jet described in this embodiment includes the following steps: first, evaluate the size of the burr on the original surface of the precision part to be Figure 7 , before finishing, the burr on the original surface of the radar antenna is <0.1mm, and there are knife lines; after finishing, the burrs in the slot are completely removed and the surface knife lines disappear, and the surface roughness meets the requirements.

[0060]In this embodiment, the mass ratios of the components of C abrasive grains: cerium oxide powder: boron carbide: artificial diamond powder: chromium oxide are (0.25-0.4): (0.2-0.4): (0.3-0.5): (0.01-0.1) ; Can be arbitrarily selected within the above-mentioned component mass ratio range.

[0061] The best choice is the components of C abrasive gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com