Preparation method of tungsten oxide/ammonium molybdate composite film for electrochromism

A composite film and electrochromic technology, applied in the direction of coating, etc., can solve the problems of long electrochromic response time and low electrochromic efficiency, and achieve short color changing response time, low overall cost, and simple and easy-to-operate preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

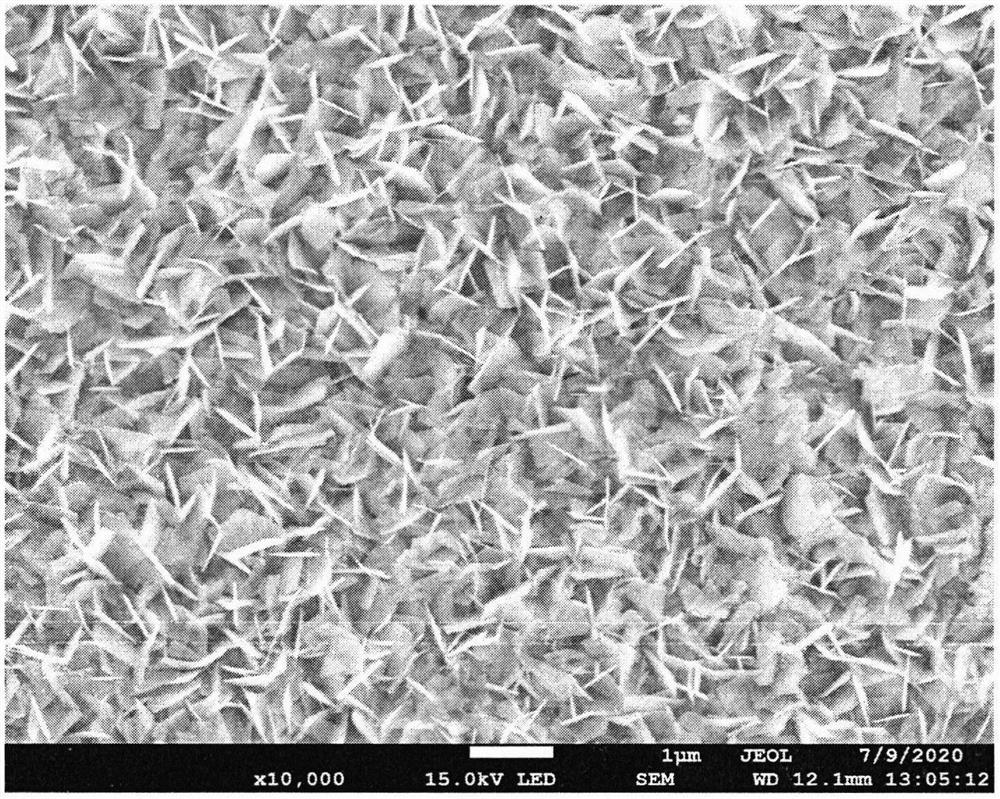

Image

Examples

Embodiment 1

[0019] A preparation method for electrochromic tungsten oxide / ammonium molybdate composite film, comprising the steps of:

[0020] (1) Add 0.6g sodium tungstate to 50mL deionized water under constant stirring, then add 0.16g potassium oxalate, adjust the pH of the solution to 1.2 by adding 3M hydrochloric acid, and stir for 40min to prepare the tungsten oxide precursor solution, The FTO glass was put into the hydrothermal kettle obliquely with the conductive side facing down, and then kept at 120 °C for 1 h through hydrothermal reaction. The prepared glass was dried in an oven for 0.5 h, and then the FTO glass was transferred to a muffle furnace for treatment, heated to 300 °C at a heating rate of 2 °C / min, kept for 1 h, and then cooled to room temperature. The tungsten oxide film attached to the FTO conductive glass can be obtained.

[0021] (2) Dissolve 0.156 g of ammonium molybdate in 100 mL of deionized water, and stir the solution for 30 min with magnetic force. 3M hydr...

Embodiment 2

[0024] A preparation method for electrochromic tungsten oxide / ammonium molybdate composite film, comprising the steps of:

[0025] (1) Add 1.2g sodium tungstate to 100mL water under constant stirring, then add 0.32g potassium oxalate, adjust the pH of the solution to 1.4 by adding 3M hydrochloric acid, and stir for 30min to obtain a tungsten oxide precursor solution. FTO The glass was put into the hydrothermal kettle obliquely with the conductive side facing down, and then kept at 140°C for 1.5h through hydrothermal reaction. The prepared glass was dried in an oven for 45 min, and then the FTO glass was transferred to a muffle furnace for processing, heated to 400 °C at a heating rate of 2 °C / min, kept for 1.5 h, and cooled to room temperature. The tungsten oxide film attached to the FTO conductive glass can be obtained.

[0026] (2) Dissolve 0.312g of ammonium molybdate in 100mL of deionized water, and magnetically stir the solution for 35min. 3M hydrochloric acid solution ...

Embodiment 3

[0029] A preparation method for electrochromic tungsten oxide / ammonium molybdate composite film, comprising the steps of:

[0030] (1) Add 1.5g sodium tungstate to 100mL water under constant stirring, then add 0.24g potassium oxalate, adjust the pH of the solution to 1.5 by adding 3M hydrochloric acid, and stir for 45min to obtain a tungsten oxide precursor solution. FTO The glass was put into the hydrothermal kettle obliquely with the conductive side facing down, and then kept at 150°C for 2h through hydrothermal reaction. The prepared glass was dried in an oven for 1 h, then the FTO glass was transferred to a muffle furnace for processing, heated to 450 °C at a heating rate of 2 °C / min, kept for 2 h, and cooled to room temperature. The tungsten oxide film attached to the FTO conductive glass can be obtained.

[0031] (2) Dissolve 0.4 g of ammonium molybdate in 100 mL of deionized water, and magnetically stir the solution for 45 min. 3M hydrochloric acid solution was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com