Rapid gelation method of polyvinyl alcohol and preparation method of polyvinyl alcohol with low alcoholysis degree

A technology of polyvinyl alcohol gel and polyvinyl alcohol, which is applied in the field of rapid gelation of polyvinyl alcohol and the preparation of polyvinyl alcohol with low degree of alcoholysis, can solve the problems of slow gelation and difficult gelation, and achieve phase transition Short time, shorter phase change gel time, phase change time and easy continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

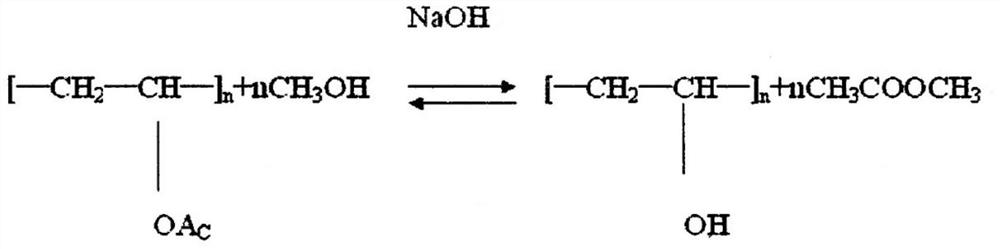

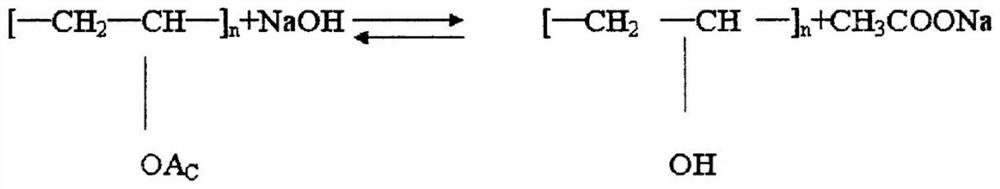

[0034] The invention provides a method for preparing polyvinyl alcohol with low degree of alcoholysis. The method for preparing polyvinyl alcohol with low degree of alcoholysis comprises the steps of quickly gelling polyvinyl alcohol to obtain polyvinyl alcohol gel, pulverizing and drying to obtain polyethylene with low degree of alcoholysis. alcohol. According to this method, when preparing polyvinyl alcohol with an alcoholysis degree of 60mol%-80mol%, the phase change gel reaction in the alcoholysis stage of PVAc can be accelerated, the gelation time can be shortened, and the finally obtained PVA product has a phase change time The characteristics of short and easy continuous production.

[0035] Specifically, the polyvinyl alcohol rapid gelation method has the following steps:

[0036] (1) Component A and Component B are mixed together to form a mixed solution, Component A is a methanol solution of polyvinyl acetate, and Component B is a non-polar organic solvent;

[0037...

Embodiment approach

[0039] In the step (1), the above-mentioned non-polar organic solvent is mixed according to the mass ratio of 10%-35% with the polyvinyl acetate. According to one embodiment of the present invention, one or more non-polar organic solvents can be added into a storage tank with a stirring device, and the stirring is turned on. After the stirring is uniform, the solvent is added to the polyacetic acid through a metering pump. in vinyl esters.

[0040] In order to further enhance the reaction effect, water can also be added to the methanol solution of polyvinyl acetate, and the water is added in a metered manner. According to a trial implementation of the present invention, the added water is added using a metering pump. Preferably, 0.3%-1% of metered water (measured according to the mass ratio to the polyvinyl acetate) is added after adding the non-polar organic solvent and mixing in the step (1).

[0041] In the method of the present invention, the process of forming polyvinyl...

Embodiment 1

[0046] Embodiment 1: alcoholysis degree is the alcoholysis reaction of polyvinyl alcohol of 78mol%

[0047] Component A is the product of vinyl acetate monomer polymerized in methanol solution, and component B is methyl acetate. Components A and B were mixed evenly in a mixer, and the mixed solution was subjected to alcoholysis reaction to form polyvinyl alcohol gel. Alkaline methanol solution was selected as the catalyst for the alcoholysis reaction. In this example, four groups were divided into four groups for simultaneous research.

[0048] (1) Group: direct alcoholysis of polyvinyl acetate (i.e. without adding any non-polar organic solvents, such as methyl acetate), the catalyst base molar ratio is: 2.86*10 -3 , the gelation time of the resin (ie, polyvinyl alcohol) was 42.7 minutes.

[0049] (2) Group: According to the mass ratio of methyl acetate and polyvinyl acetate is 10%, methyl acetate is added to the methanol solution of polyvinyl acetate, and the catalyst base m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com