A kind of high zinc layer optical cable stranded wire and its preparation process

A preparation process, high zinc technology, applied in metal material coating process, hot dip plating process, coating and other directions, can solve problems such as shortening service life, pitting corrosion and rusting, etc. The effect of enhancing the degree of substance binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a high-zinc layer optical cable stranded wire, comprising: stainless steel wire, a modification solution and a galvanized base material, the galvanized base material is arranged on the outer wall of the stainless steel wire, and the modification solution is arranged on the stainless steel wire and the galvanized base material;

[0027] The modification solution, calculated by weight percentage, includes: 1.25% silicon carbide nanowires, 0.94% single-wall carbon nanohorns, 1.96% cellulose nanowhiskers, and the rest is ethanol;

[0028] The invention also provides a preparation process of the high zinc layer optical cable stranded wire, and the specific preparation steps are as follows:

[0029] Step 1: Prepare the modification solution: weigh the above percentages of silicon carbide nanowires, single-wall carbon nanohorns, cellulose nanowhiskers and ethanol, and then mix the silicon carbide nanowires, single-walled carbon nanohorns, cellulose nanow...

Embodiment 2

[0040] The difference from Example 1 is that the modification liquid includes 1.75% of silicon carbide nanowires, 1.36% of single-walled carbon nanohorns, 2.84% of cellulose nanowhiskers, and the rest is ethanol by weight percentage.

Embodiment 3

[0042] The difference from Examples 1-2 is that the modification liquid, calculated by weight percentage, includes: 1.50% silicon carbide nanowires, 1.15% single-walled carbon nanohorns, 2.40% cellulose nanowhiskers, and the rest is ethanol .

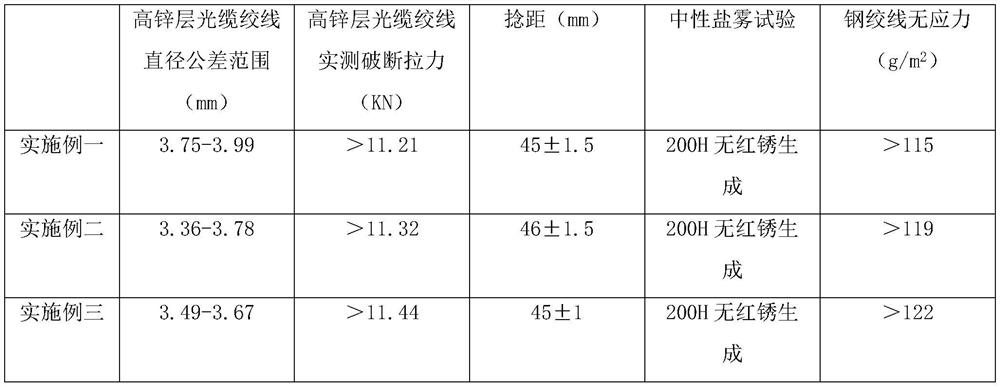

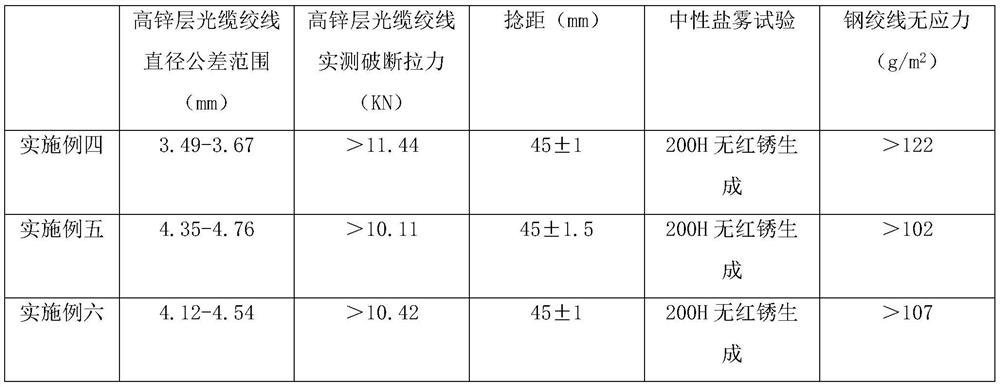

[0043] Take the high-zinc-layer optical cable stranded wires prepared in the above-mentioned examples 1-3 respectively for experiments, and test the high-zinc-layer optical cable stranded wires prepared in the three examples in three groups, and each 30 samples is a group for testing. , the test results are shown in Table 1:

[0044] Table I:

[0045]

[0046] It can be seen from Table 1 that when the raw material ratio of the modification liquid in the high-zinc layer optical cable stranded wire is: 1.50% silicon carbide nanowires, 1.15% single-wall carbon nanohorns, 2.40% cellulose nanowhiskers, and the rest is ethanol. , which can effectively ensure the high tensile and corrosion resistance performance requirements of the high-z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com