Industrial monitoring control system based on industrial internet platform

A control system and industrial technology, which is applied in the direction of combustion method, indirect carbon dioxide emission reduction, non-rotating equipment cleaning, etc., can solve problems such as clogging, corrosion, and real-time monitoring of non-blocking status, so as to achieve fast operation speed, ensure real-time performance, The effect of convenient and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

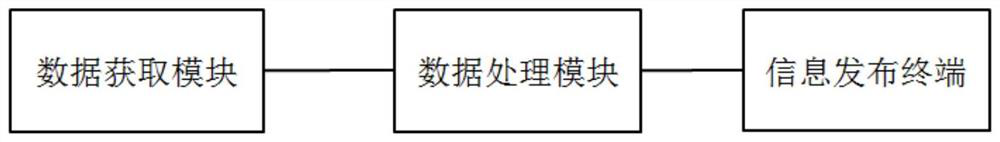

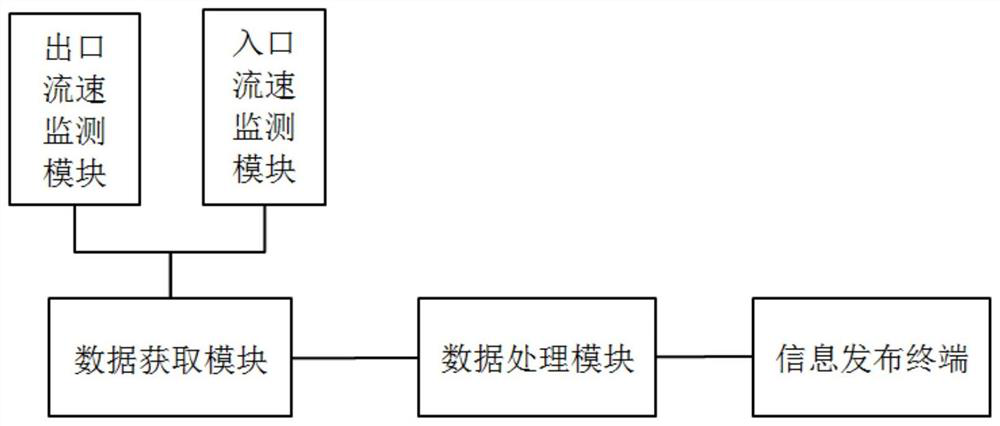

[0032] like Figure 1-2 , the present invention provides an industrial monitoring and control system, the system includes a data acquisition module and an information release terminal that are both signal-connected to the data processing module;

[0033] The data acquisition module is used to acquire blockage-related status information of at least one of the sub-bins of the rotary air preheater;

[0034] The data processing module is used to determine the clogging level of the rotary air preheater according to the status information related to the clogging; the clogging level is used to characterize the clogging degree of the entire rotary air preheater, and according to the The level of clogging determines whether cleaning measures are required;

[0035] The information release terminal is used to release the processing information of the data processing module, so that users can learn specific monitoring information, early warning information, and processing suggestions;

...

Embodiment 2

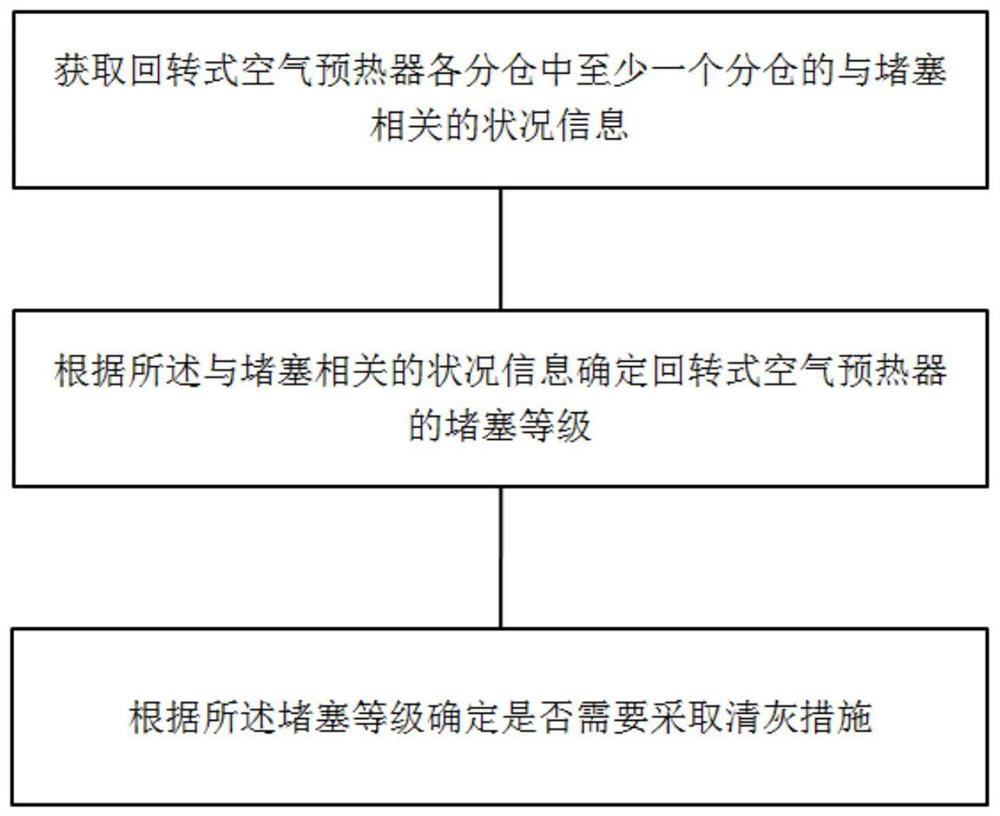

[0060] like image 3 As shown, the present invention provides a kind of industrial monitoring control method, and described method comprises:

[0061] Obtaining blockage-related status information of at least one of the sub-chambers of the rotary air preheater;

[0062] Determine the clogging level of the rotary air preheater according to the status information related to the clogging, and the clogging level is used to characterize the clogging degree of the entire rotary air preheater;

[0063] Determine whether to take dust removal measures according to the clogging level;

[0064] Wherein, the congestion level requiring measures to be taken is greater than the level of congestion requiring no measures to be taken.

[0065] Further, the acquisition of blockage-related status information of at least one of the sub-bins of the rotary air preheater at least includes the outlet flow rate and inlet flow rate of the sub-bins currently monitored by the rotary air preheater;

[0...

Embodiment 3

[0084] like Figure 4 As shown, the present invention provides an industrial monitoring device, including a memory and a processor; the memory is used to store a computer program; and the processor is used to execute the computer program to realize the above-mentioned embodiment 2. Industrial monitoring and control methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com