Preparation method of NiO/ZrO2 nano-composite photocatalyst and application of catalyst

A photocatalyst and nanocomposite technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of degradation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

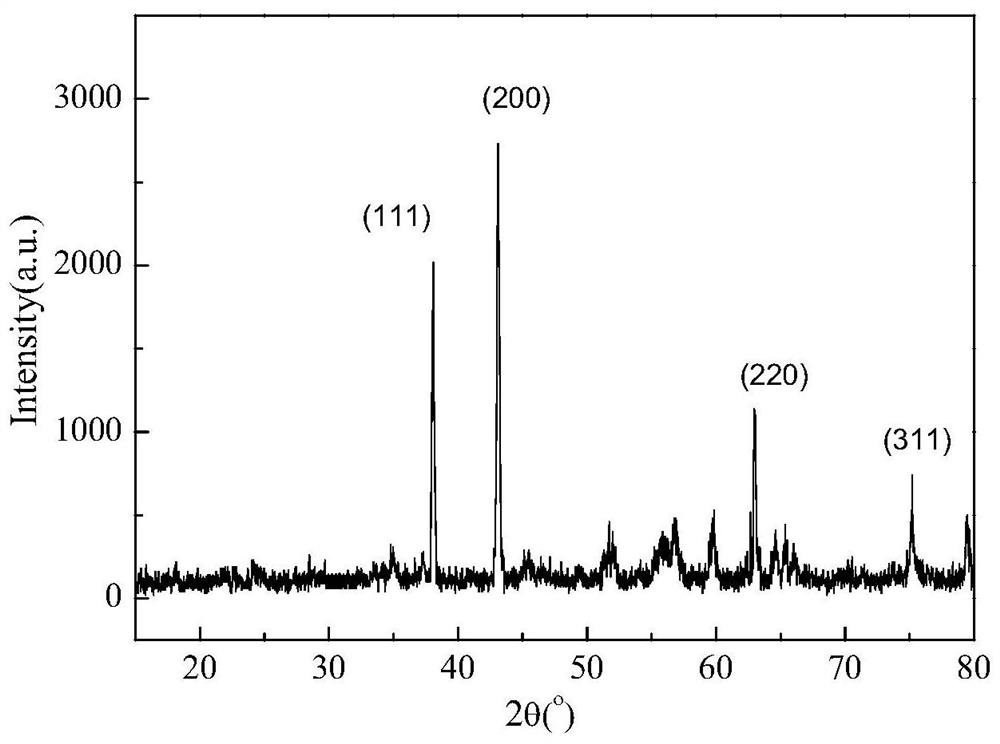

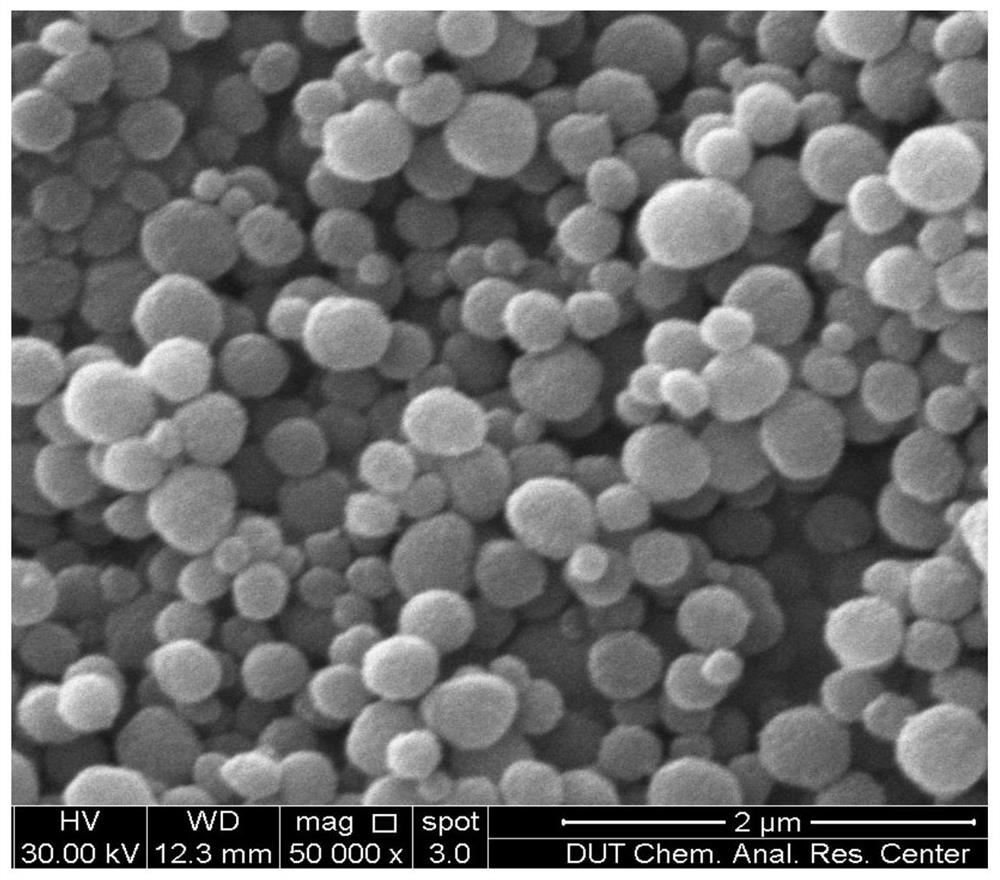

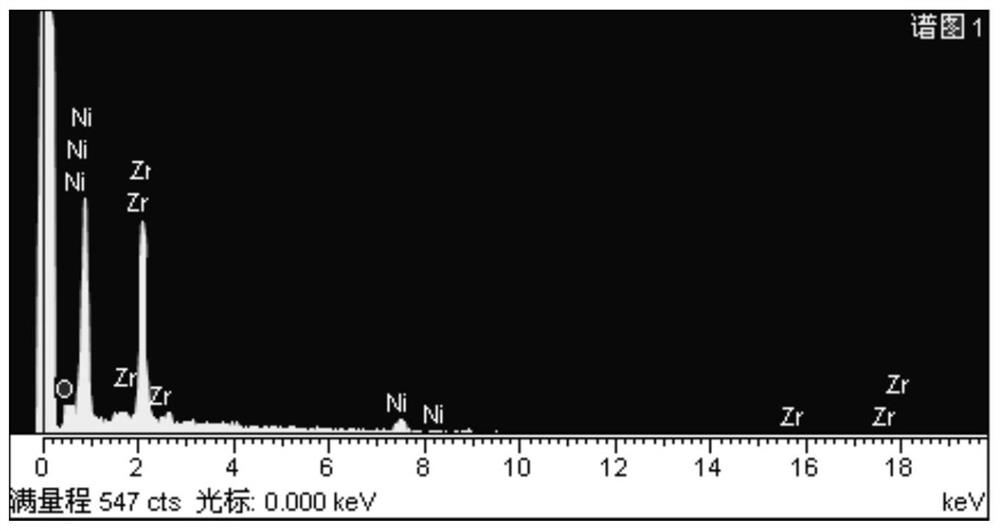

[0033] 5L 0.2mol / L NaBH 4 The solution was added dropwise to 5L of 0.1mol / L ZrOCl 2 ·8H 2 O solution forms a white sol, stir vigorously until a precipitate forms; then filter and wash until the filtrate is neutral, filter, and dry at 80°C for 6 hours; add the precipitate to 5L of 0.5mol / L (NH 4 ) 2 CO 3 solution and 0.9L 0.1mol / L Ni(NO 3 ) 2 ·6H 2 In the O solution, first stir for 20 minutes, then ultrasonically disperse for 20 minutes, let stand for 3 hours, then vacuum dry at 80°C for 8 hours, bake at 350°C for 3 hours, and grind to obtain NiO / ZrO 2 Nanocomposite photocatalysts. The mole fraction of Ni added is 15%.

[0034] The NiO / ZrO 2 Application of nanocomposite photocatalyst: prepare a p-methylene blue (MB) solution with a concentration of 60 mg / L as simulated wastewater, and mix NiO / ZrO 2 Nanocomposite photocatalyst added to MB solution, NiO / ZrO 2 The dosage of the nanocomposite photocatalyst is 0.6g / L; the degradation reaction occurs for 1.2h under the con...

Embodiment 2

[0036] 5L 0.2mol / L NaBH 4 The solution was added dropwise with 4L of 0.1mol / L ZrOCl 2 ·8H 2 O solution forms a white sol, stir vigorously until a precipitate forms; then filter and wash until the filtrate is neutral, filter, and dry at 90°C for 5 hours; add the precipitate to 2L of 0.5mol / L (NH 4 ) 2 CO 3 solution and 1L 0.1mol / L Ni(NO 3 ) 2 ·6H 2 In the O solution, first stir for 25 minutes, then ultrasonically disperse for 25 minutes, let stand for 2 hours, then vacuum dry at 85°C for 9 hours, roast at 380°C for 3 hours, and grind to obtain NiO / ZrO 2 Nanocomposite photocatalysts. Among them, the mole fraction of Ni added is 20%.

[0037] The NiO / ZrO 2 Application of nanocomposite photocatalyst: prepare a p-methylene blue (MB) solution with a concentration of 60 mg / L as simulated wastewater, and mix NiO / ZrO 2 Nanocomposite photocatalyst added to MB solution, NiO / ZrO 2 The dosage of the nanocomposite photocatalyst is 0.6g / L; the degradation reaction occurs for 1.5h ...

Embodiment 3

[0039] 6L 0.2mol / L NaBH 4 The solution was added dropwise with 4.5L of 0.2mol / L ZrOCl 2 ·8H 2 O solution forms a white sol, stir vigorously until a precipitate forms; then filter and wash until the filtrate is neutral, filter, and dry at 80°C for 6 hours; add the precipitate to 3L of 1.0mol / L (NH 4 ) 2 CO 3 solution and 1L 0.1mol / L Ni(NO 3 ) 2 ·6H 2 In the O solution, first stir for 30 minutes, then ultrasonically disperse for 20 minutes, let stand for 4 hours, then vacuum dry at 90°C for 8 hours, bake at 400°C for 2 hours, and grind to obtain NiO / ZrO 2 Nanocomposite photocatalysts. The mole fraction of Ni added is 10%.

[0040] The NiO / ZrO 2 Application of nanocomposite photocatalyst: prepare a p-methylene blue (MB) solution with a concentration of 60 mg / L as simulated wastewater, and mix NiO / ZrO 2 Nanocomposite photocatalyst added to MB solution, NiO / ZrO 2 The dosage of the nanocomposite photocatalyst is 0.6g / L; the degradation reaction occurs for 1.0h under the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com