A preparation method of titanium/aluminum bimetallic composite material with curved surface self-forming characteristics

A composite material and forming feature technology, which is applied in the field of titanium/aluminum bimetallic composite materials and preparation, can solve the problems of increasing the difficulty of secondary machining, and achieve the effects of avoiding secondary machining, simple process, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

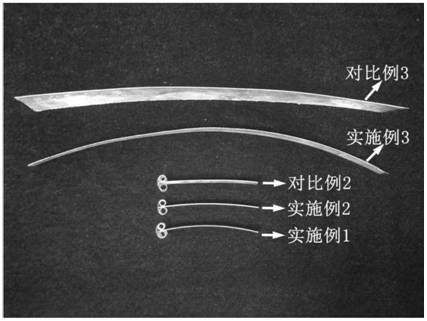

Embodiment 1

[0019] The preparation method of the surface self-forming feature of the present embodiment of the titanium / aluminum bimetallic composite is carried out in accordance with the following steps:

[0020] Step 1: Prepare TC4 titanium alloy sheets with dimensions of 0.3 (thickness) ×10 (width) ×80mm (length) and 0.3 (thickness) ×10 (width) ×80mm aluminum alloy sheets;

[0021] Step 2: The surface of the titanium alloy sheet and the aluminum alloy sheet in step 1 is polished with 200#, 400#, 600#, 800#, 1000#, 1500# water sandpaper step by step, and then the surface polishing agent with a particle size of 0.5μm is used for surface polishing, and finally ultrasonically cleaned with acetone and alcohol for 10min, blown dry.

[0022] Step 3: After the surface treatment, the two sheets of titanium and aluminum are stacked up and down and closely fitted into the vacuum hot press furnace, and the vacuum degree in the furnace is maintained at 3×10 -3 Pa, heated from room temperature at 10 °...

Embodiment 2

[0025] The preparation method of the surface self-forming feature of the present embodiment of the titanium / aluminum bimetallic composite is carried out in accordance with the following steps:

[0026] Step 1: Prepare TC4 titanium alloy sheets with dimensions of 0.3 (thickness) ×10 (width) ×80 (length) mm and 0.5 (thickness) ×10 (width) ×80 (length) mm of 2A12 aluminum alloy sheets;

[0027] Step 2: The surface of the titanium alloy sheet and the aluminum alloy sheet in step 1 is polished with 200#, 400#, 600#, 800#, 1000#, 1500# water sandpaper step by step, and then the surface polishing agent with a particle size of 0.5μm is used for surface polishing, and finally ultrasonically cleaned with acetone and alcohol for 10min, blown dry.

[0028]Step 3: After the surface treatment, the two sheets of titanium and aluminum are stacked up and down and closely fitted into the vacuum hot press furnace, and the vacuum degree in the furnace is maintained at 3×10 -3 Pa, heated from room t...

Embodiment 3

[0031] The preparation method of the surface self-forming feature of the present embodiment of the titanium / aluminum bimetallic composite is carried out in accordance with the following steps:

[0032] Step 1: Prepare TC4 titanium alloy sheets with dimensions of 0.3 (thickness) ×10 (width) ×300 mm and 2A12 aluminum alloy sheets of 0.3 (thickness) ×10 (width) ×300 (length) mm;

[0033] Step 2: The surface of the titanium alloy sheet and the aluminum alloy sheet in step 1 is polished with 200#, 400#, 600#, 800#, 1000#, 1500# water sandpaper step by step, and then the surface polishing agent with a particle size of 0.5μm is used for surface polishing, and finally ultrasonically cleaned with acetone and alcohol for 10min, blown dry.

[0034] Step 3: After the surface treatment, the two sheets of titanium and aluminum are stacked up and down and closely fitted into the vacuum hot press furnace, and the vacuum degree in the furnace is maintained at 3×10 -3 Pa, heated from room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com