Corrosion protection method for movable guide vane of seawater pump turbine

A technology of water pump turbine and movable guide vane, which is applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of galvanic corrosion, crevice corrosion, short service time of movable guide vane, etc., and achieve high wear resistance. The effect of damage and erosion resistance, good shielding effect, uniform and dense organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode 1: In this implementation mode, a corrosion protection method for movable guide vanes of seawater pump turbines is completed according to the following steps:

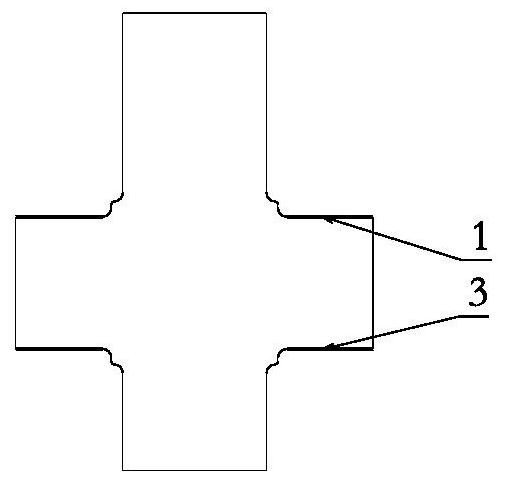

[0016] 1. Clean the surfaces of the upper shoulder 1 and the lower shoulder 3 of the movable guide vane: polish the surfaces of the upper shoulder 1 and the lower shoulder 3 of the movable guide vane, then use an organic solvent to clean and dry to obtain the The treated active guide vane;

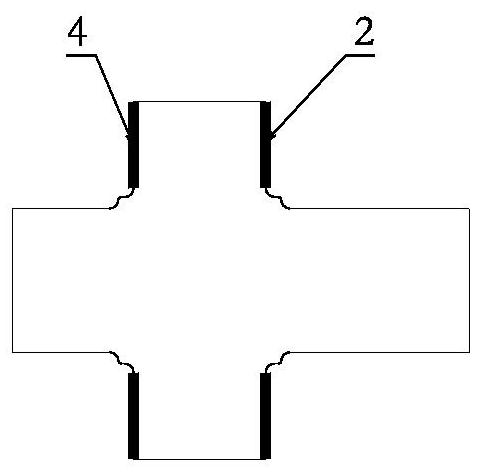

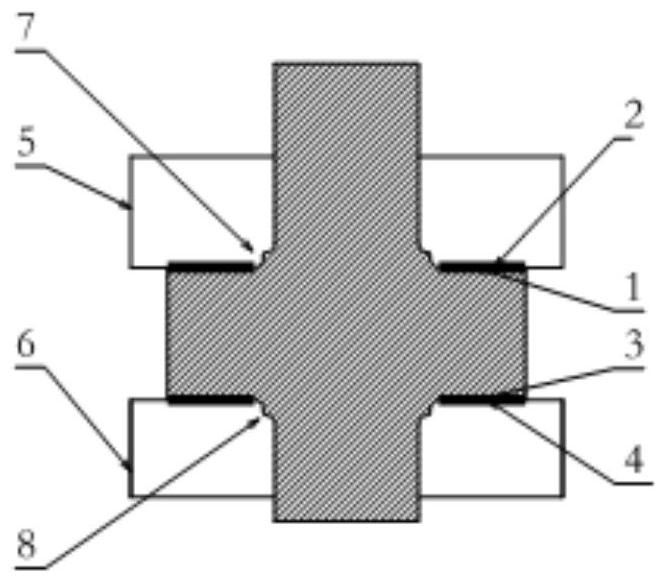

[0017] 2. Arc spraying of upper shoulder 1 and supersonic flame spraying of lower shoulder 3: Spray the surface of upper shoulder 1 of the pretreated movable guide vane with arc spraying equipment to form NiCr coating 2 and NiCr coating 2 The thickness is less than the distance between the upper shoulder 1 and the top cover 5; the surface of the lower shoulder 3 is sprayed with supersonic flame spraying equipment to form Cr 2 C 3 -25% NiCr coating 4, Cr 2 C 3 The thickness of the -25% NiCr co...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the surface roughness of the upper shoulder of the movable guide vane is polished to 3.2-6.3.

[0022] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the surface roughness of the lower shoulder of the movable guide vane is polished to 1.6-3.2.

[0024] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com