Mixed ionic liquid corrosion inhibitor and preparation method and application thereof

A kind of ionic liquid and mixed type technology, which is applied in the field of preparation of metal corrosion inhibitors, can solve the problems of low acid concentration of corrosive medium and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

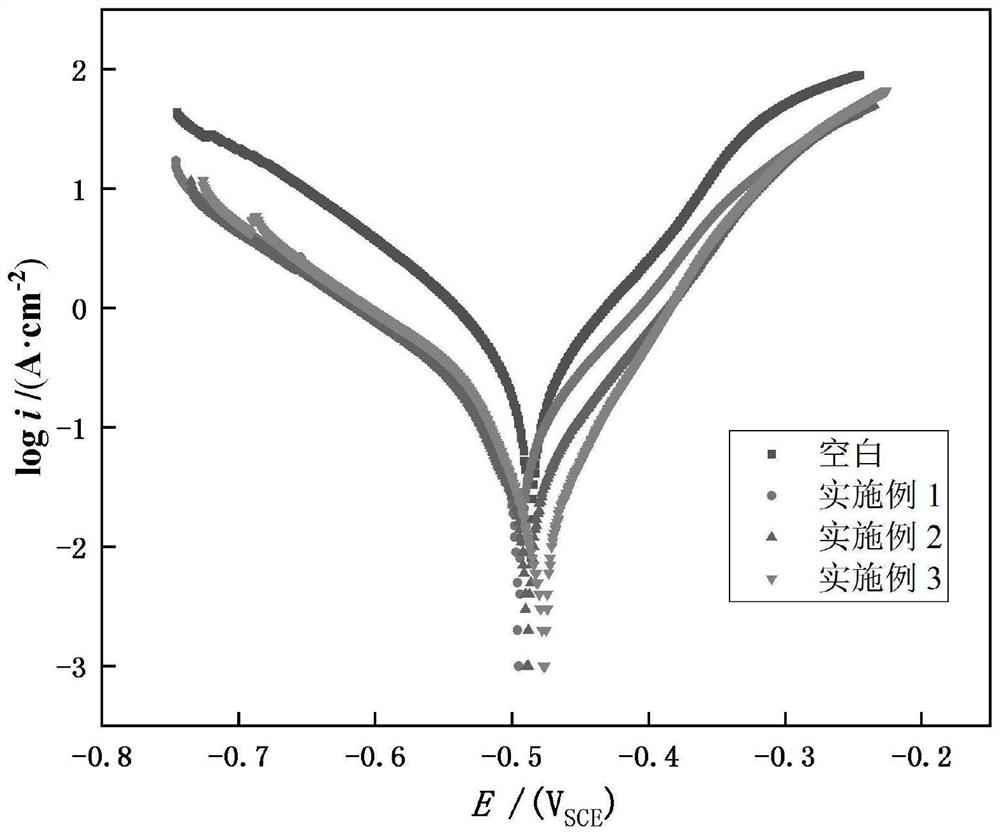

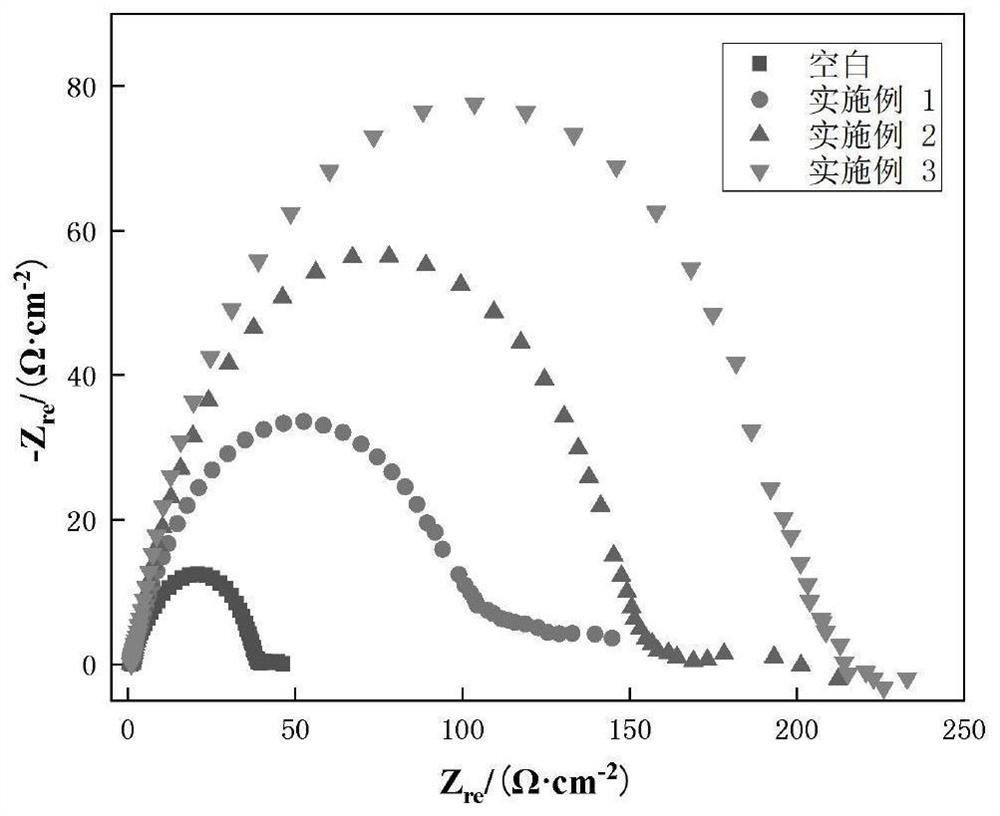

Embodiment 1

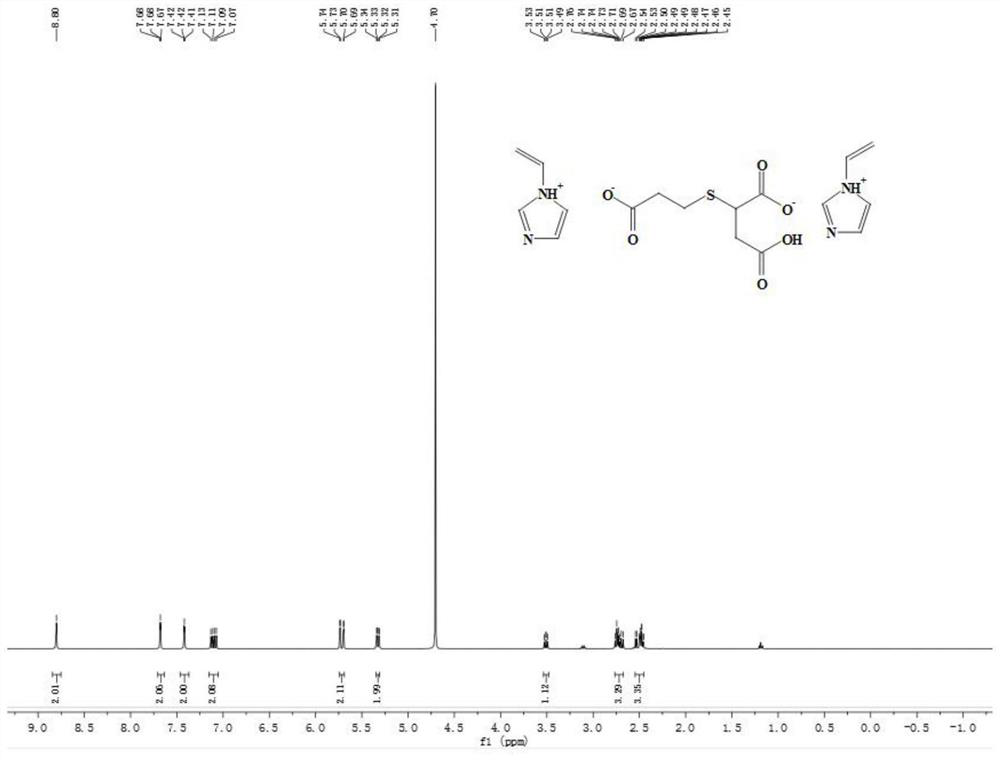

[0017] Embodiment 1: the ionic liquid synthesized by urotropine and carboxyethylthiosuccinic acid (CETSA)

[0018] Two raw materials, urotropine (28g, 0.2mol) and CETSA (88.88g, 0.4mol), and 100mL ethanol solvent were added to a four-necked flask under nitrogen protection, and a magnetic stirring rotor was installed, and the flask was placed The reaction was carried out in a magnetic stirrer heated in an oil bath at 70° C. for 24 h.

[0019] After the reaction was over, nitrogen gas was slowly released, and the reaction solution was transferred to a 200mL single-necked flask, placed on a rotary evaporator, and the temperature was set at 60°C until all the ethanol solvent was evaporated. The reaction yield was 95%.

Embodiment 2

[0020] Embodiment 2: the ionic liquid synthesized by urotropine and β-mercaptopropionic acid

[0021] Two kinds of raw materials of urotropine (28g, 0.2mol) and β-mercaptopropionic acid (106.14g, 1mol), and 150mL of acetone solvent were added to a four-necked flask under nitrogen protection, and a magnetic stirring rotor was put into it, The flask was placed in an oil bath heating magnetic stirrer at 40°C for 12 hours.

[0022] After the reaction was over, nitrogen gas was slowly released, and the reaction solution was transferred to a 200mL single-necked flask, placed on a rotary evaporator, and the temperature was set at 45°C until all the acetone solvent was evaporated. The reaction yield was 94%.

Embodiment 3

[0023] Embodiment 3: the ionic liquid synthesized by urotropine and maleic acid

[0024] Two raw materials, urotropine (28g, 0.2mol) and maleic acid (116.07g, 0.8mol), and 150mL of methanol solvent were added to a four-necked flask under nitrogen protection, and a magnetic stirring rotor was placed, The flask was placed in an oil bath heating magnetic stirrer at 60°C for 20 h.

[0025] After the reaction, nitrogen was slowly released, and the reaction liquid was transferred to a 200mL single-necked flask, placed on a rotary evaporator, and the temperature was set at 55°C until all the methanol solvent was evaporated. The reaction yield was 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com