Preparation of a graphene/silicon carbide three-dimensional composite aerogel and its supported molybdenum disulfide electrocatalyst

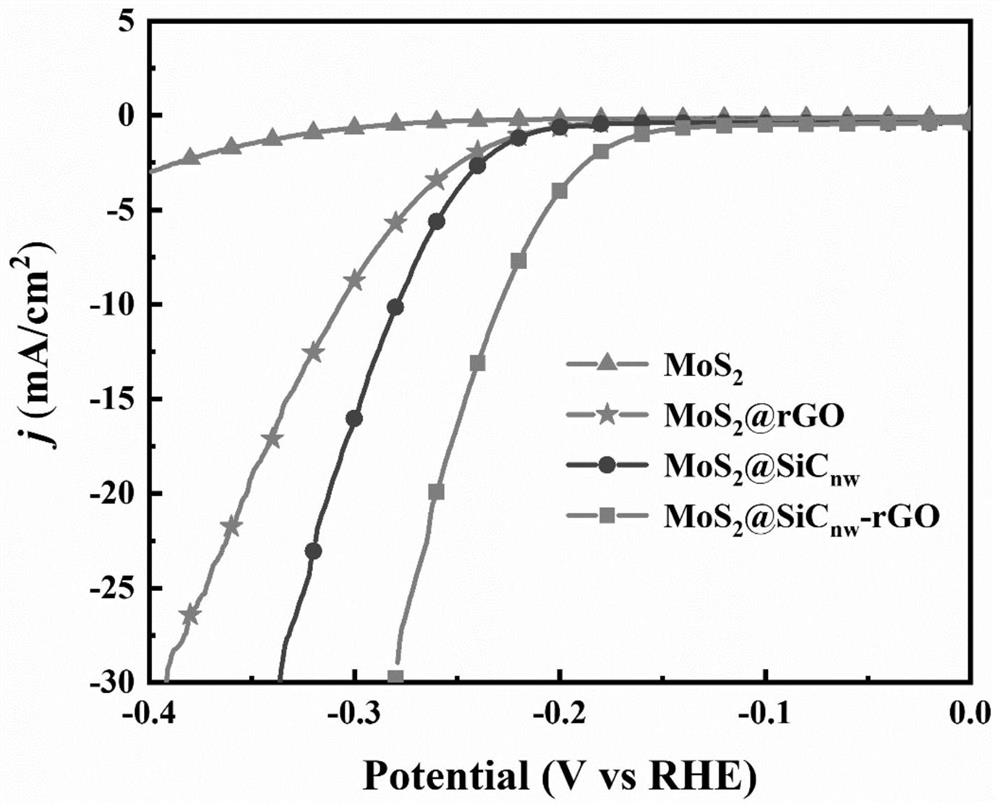

A three-dimensional composite, molybdenum disulfide technology, applied in electrodes, electrolysis components, electrolysis process, etc., to achieve the effect of reducing activation barrier, enhancing electrocatalytic hydrogen production performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

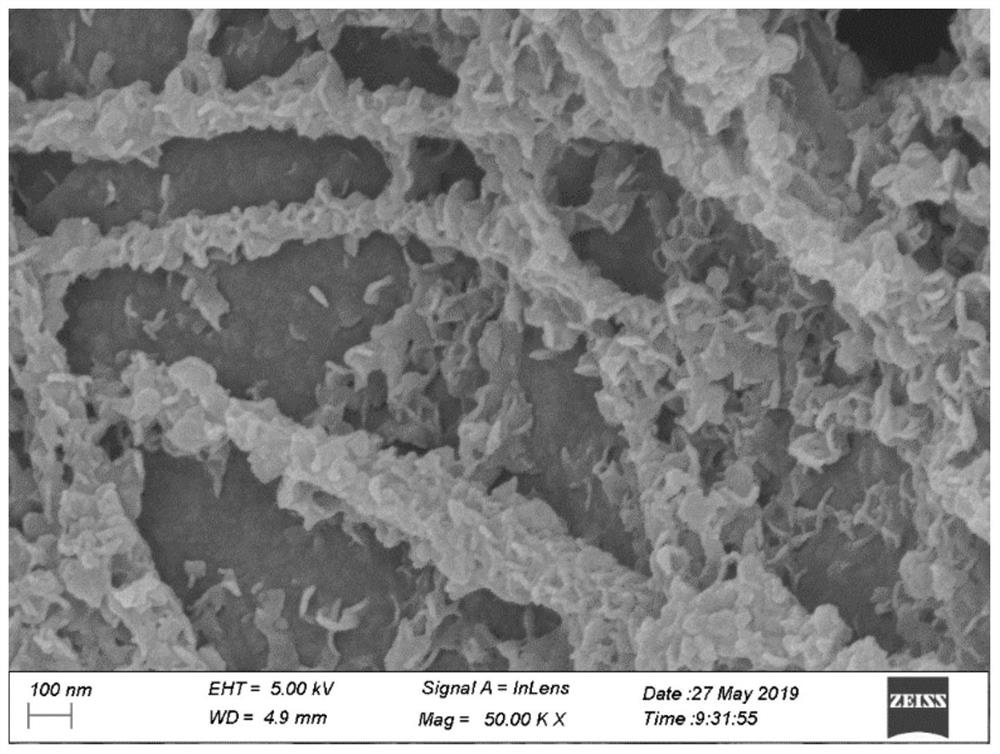

[0030] A method for preparing a graphene / silicon carbide three-dimensional composite aerogel and a method for supporting a molybdenum disulfide electrocatalyst, comprising the following steps: mixing 0.5 g of graphene and 0.86 g of silica sol in a solvent of water and ethanol, pumping Filter into a block and dry at 120 °C; mix 20 g of carbon felt with 3.7 g of silica sol in a solvent of water and ethanol, and dry at 120 °C; spread the carbon felt on the bottom of a graphite crucible, and then suction filtration to obtain The graphene block was placed on top of the carbon felt, and the crucible lid was covered; under the protection of 0.5MPa argon, it was heated to 1300°C at a heating rate of 5°C / min, and kept at 1300°C for 2 h to obtain graphene / carbonized Silicon three-dimensional composite aerogel. Take 0.6g sodium molybdate and 0.75g thioacetamide into 30mL deionized water, stir for 30 minutes, then add 0.01g graphene / silicon carbide three-dimensional composite aerogel, soa...

Embodiment 2

[0035] A method for preparing a graphene / silicon carbide three-dimensional composite aerogel and a method for supporting a molybdenum disulfide electrocatalyst, comprising the following steps: mixing 0.9 g of graphene and 1.2 g of silica sol in a solvent of water and ethanol, pumping Filter into a block and dry at 120 °C; mix 22 g of carbon felt with 4.5 g of silica sol in a solvent of water and ethanol, and dry at 120 °C; spread the carbon felt on the bottom of a graphite crucible, and then suction filtration to obtain The graphene block was placed on top of the carbon felt, and the crucible lid was covered; under the protection of 0.8MPa argon, it was heated to 1450°C at a heating rate of 8°C / min, and kept at 1450°C for 2 h to obtain graphene / carbonized Silicon three-dimensional composite aerogel. Add 0.6g sodium molybdate and 0.75g thioacetamide into 30mL deionized water, stir for 30 minutes, then add 0.01g graphene / silicon carbide three-dimensional composite aerogel, soak ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com