Method for evaluating blackening tendency of zinc-aluminum-magnesium coated steel plate

A coated steel plate and evaluation method technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of unsatisfactory appearance of the car body, black reference basis of difficult-to-zinc-aluminum-magnesium-coated steel plates, etc., so as to avoid making the car body and ensure the surface Quality, accurate evaluation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044]As an implementation manner of the embodiment of the present invention, the non-oxidizing acidic solution is any one of the following: dilute hydrochloric acid, phosphoric acid, glycine acid solution, and ammonium chloride solution. Because some dilute acids are oxidizing, they will seriously interfere with the removal effect of the surface oxide film. Therefore, the present invention uses a non-oxidizing acidic solution. This acidic solution can be an acid solution or a salt, including but not limited to any of the following: One: dilute hydrochloric acid, phosphoric acid, glycine solution, ammonium chloride solution, citric acid.

[0045] As an implementation manner of the embodiment of the present invention, the drying is carried out by blowing the rinsed zinc-aluminum-magnesium-coated steel sheet with an airflow at a temperature of 30-40° C. at a rate of ≥0.1 m / s.

[0046] The drying air flow is to speed up the evaporation of deionized water and eliminate residual mo...

Embodiment 1-6 and comparative example 1-6

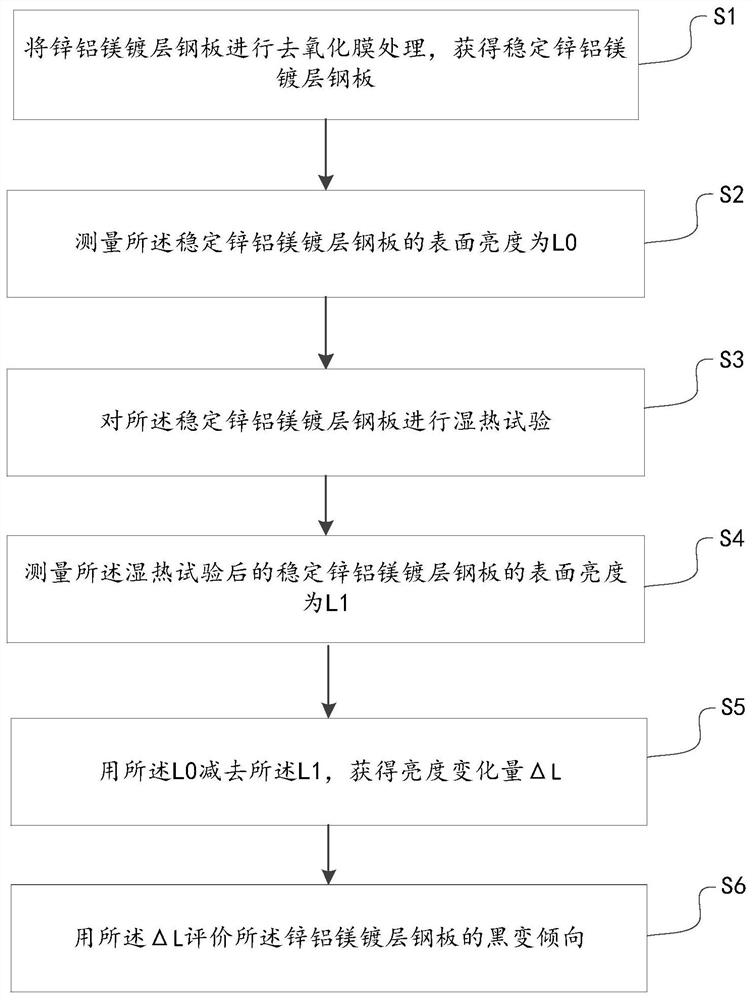

[0057] Embodiment 1-6 and comparative example 1-6 provide a kind of blackening tendency evaluation method of zinc-aluminum-magnesium coated steel plate, comprising the following steps:

[0058] (1) Soak the zinc-aluminum-magnesium-coated steel sheet in an acidic solution for a period of time, then rinse it with deionization, and then dry it with a dry air flow; the contents of magnesium and aluminum in the coating of the zinc-aluminum-magnesium-coated steel sheet are shown in the table , and the rest are Zn and unavoidable impurities;

[0059] (2) The surface brightness of the zinc-aluminum-magnesium-coated steel plate after the measurement step (1) is L0;

[0060] (3) Laminating the zinc-aluminum-magnesium-coated steel sheets treated in step (1), and placing them in a hot and humid environment under a constant pressure perpendicular to the steel sheets for storage for a period of time;

[0061] (4) the surface brightness of the zinc-aluminum-magnesium-coated steel plate afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com