High-precision real-time three-dimensional measurement system and method for measuring micro defects on surface of aviation component

A real-time three-dimensional, measurement system technology, applied in the direction of optical testing flaws/defects, measuring devices, and material analysis through optical means, can solve problems such as integrability, poor portability, large number of components, and complex systems, etc., to achieve Good beam stability, good imaging effect, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

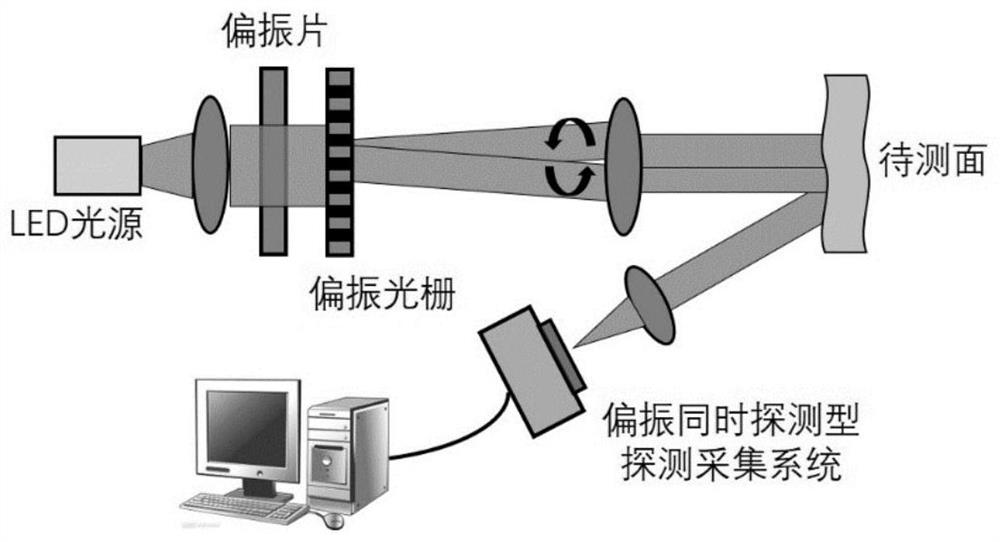

[0033] Such as figure 1 As shown, the structure schematic diagram of the high-precision real-time three-dimensional measurement system for measuring micro-defects on the surface of aerospace components of the present invention includes a light source system, a polarized light modulation subsystem, a target to be measured, a detection and acquisition system, and a computer processing system.

[0034] The light source system can select the wavelength according to the material of the detection component. The detection component is a metal material as an example, and the light source adopts a 450nm blue LED.

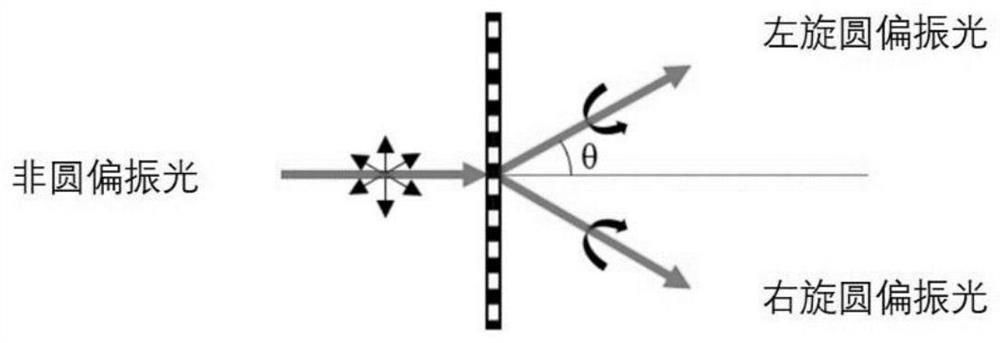

[0035] The polarization modulation subsystem includes two parts: a beam collimation component and a polarization state modulation component arranged sequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com