Electricity meter detection assembly line

An assembly line and electric meter technology, applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of difficult connection and transition of the assembly line, large space occupied by the assembly line, and labor-intensive testing time, so as to solve errors and improve production. Efficiency and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

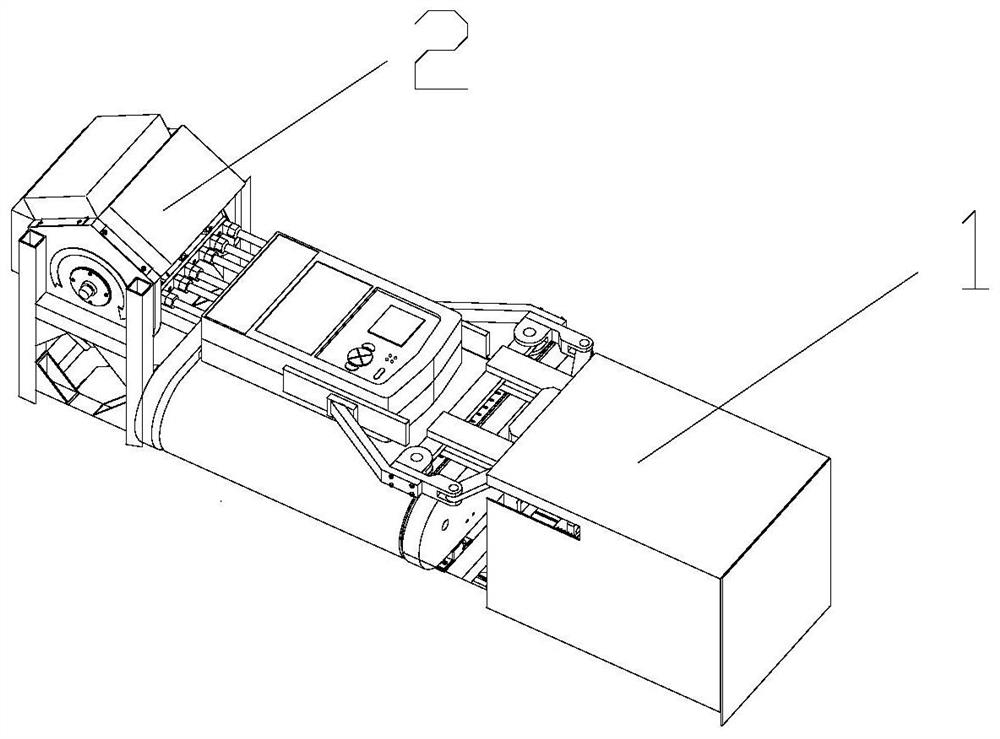

[0080] Such as figure 2 The detection unit of the automatic detection electric meter shown includes a clamp-type manipulator 1 for adjusting the position of the electric meter to realize electric meter detection, and an automatic detection mechanism 2 for realizing detection of different standard electric meters. The automatic detection mechanism 2 is set on the clamp-type manipulator 1 The opposite side of the electric meter is ensured that the automatic detection mechanism 2 can detect the electric meter after the clamp-type manipulator 1 clamps the electric meter. Moreover, the clamp-type manipulator 1 and the automatic detection mechanism 2 are associated and work together through the control system.

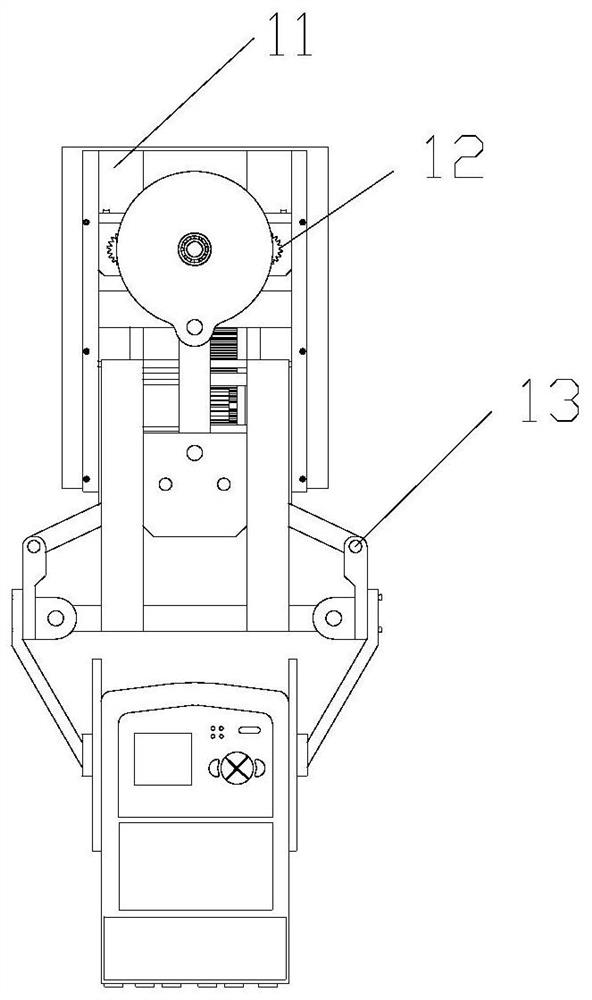

[0081] Such as image 3 As shown, the clamp-type manipulator 1 includes a base 11 for adjusting the position of the manipulator, a clamp arm driving mechanism 12 for reducing the clamping accuracy, and a clamp arm mechanism 13 for clamping the electric meter. The clamping...

Embodiment 2

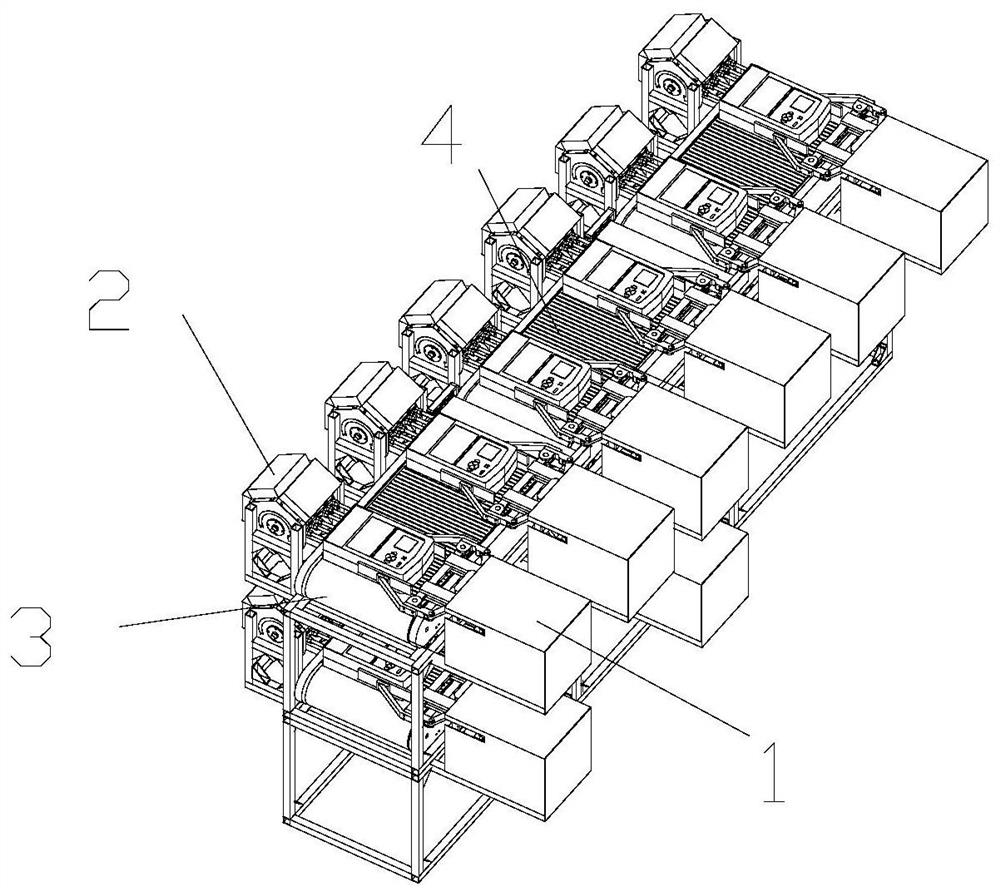

[0093] A kind of ammeter detection assembly line as shown in embodiment 1, its difference is only, as figure 1 As shown, the electric meter detection pipeline includes multiple sets of detection units, transmission mechanism 3, and transmission transition device 4, and the detection units, transmission mechanism 3, and transmission transition device 4 are all controlled by the control system and sensors. Wherein the clamp-type manipulator 1 and the automatic detection mechanism 2 are arranged on both sides of the transmission mechanism 3 respectively, and the transmission transition device 4 is arranged between the two transmission mechanisms 3 connected end to end. In the electric meter detection pipeline, each group of detection units is responsible for detecting one index of the electric meter. After the detection of one index is completed, the electric meter is sent to the next detection unit by the transmission mechanism 3 for detection, thereby realizing pipeline detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com