Holographic grating preparation system and method

A preparation system, holographic grating technology, applied in the direction of diffraction grating, optics, optical components, etc., can solve the problems of affecting the efficiency of holographic grating, low flexibility, complex design of holographic waveguide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

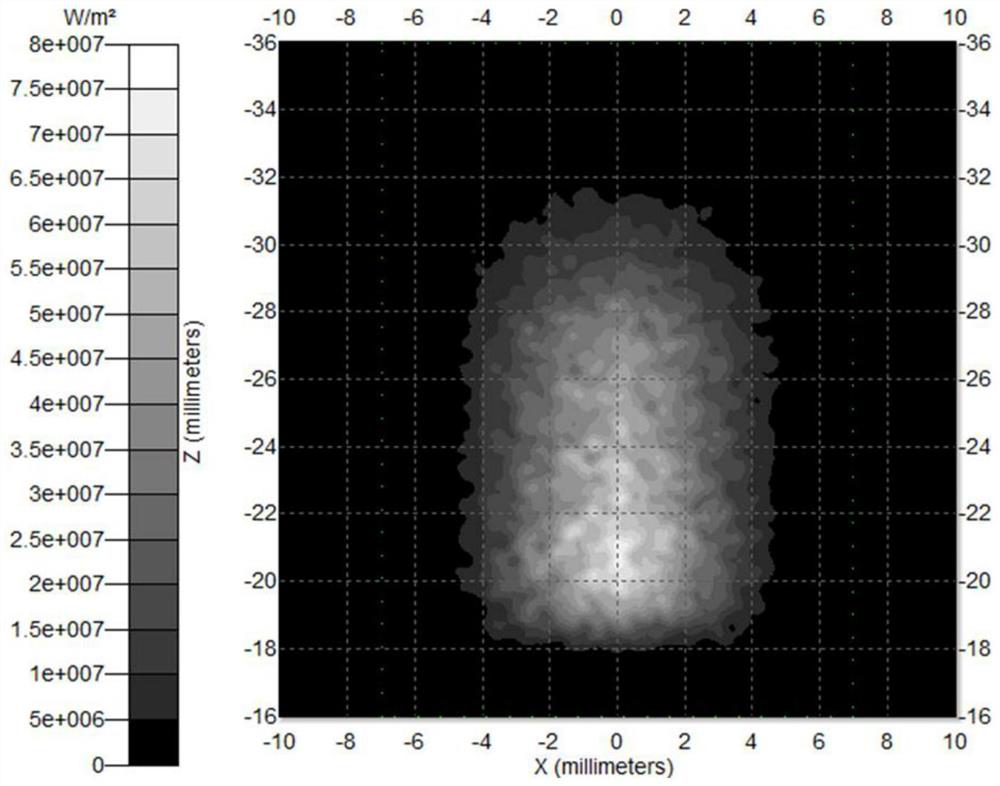

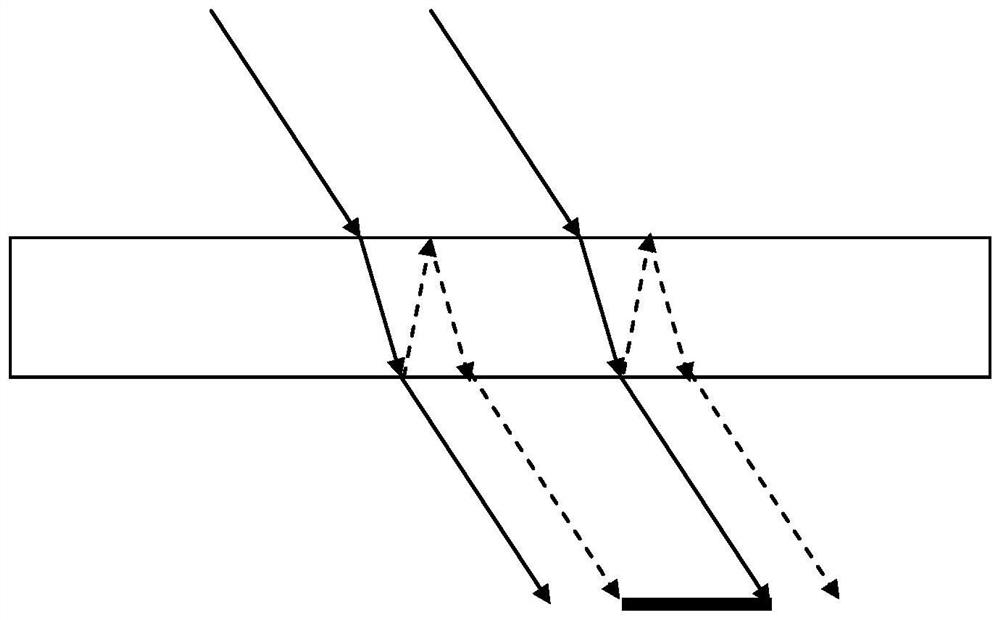

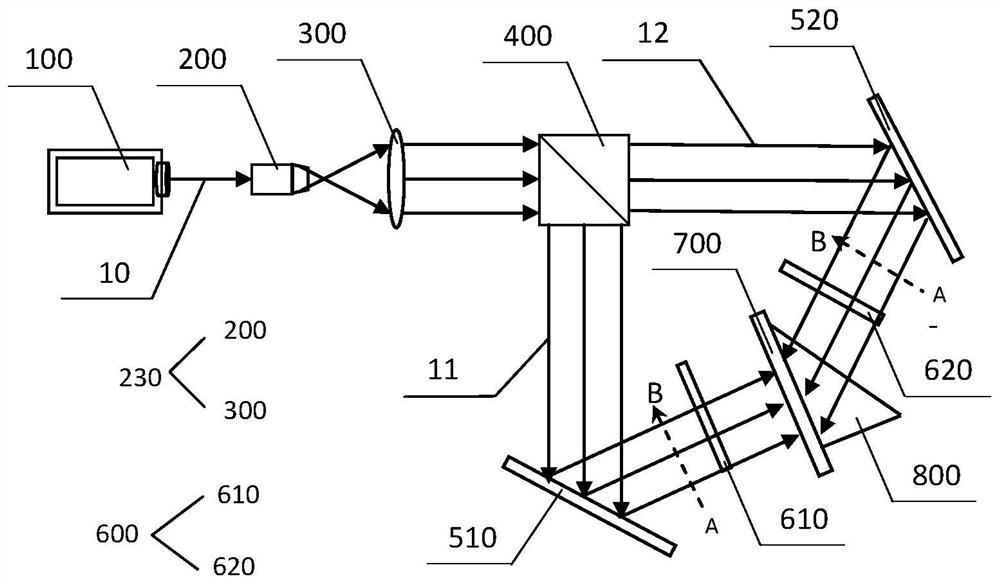

[0027] This embodiment provides a preparation system for a holographic grating, such as Figure 3-4 As shown, it includes: a light source 100 for emitting a source beam 10, a beam expander 230 arranged between the light source and the holographic material for expanding the passing beam, and used for splitting the source beam 10 into first split beams The spectroscopic device 400 for the beam 11 and the second split beam 12 is used to respectively reflect the first split beam 11 and the second split beam 12 to the first reflective device 510 and the second reflective device 520 of the holographic material 700 for The second split beam 520 is coupled into the light guide prism 800 in the holographic material 700, the holographic material 700 for receiving the first split beam 11 and the second split beam 12, the first split beam 11 and the second split beam The light beam 12 forms interference fringes on the holographic material 700 to expose the holographic material 700 to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com