FRP membrane shell for reinforcing bridge pier and pile foundation and underwater structure reinforcing construction method

A technology of underwater structure and construction method, which is applied in the direction of basic structure engineering, bridge reinforcement, and basic structure repair, etc. It can solve problems such as endangering the safety of use, difficult to find, and damage, and achieve the effect of improving bearing capacity and easy forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

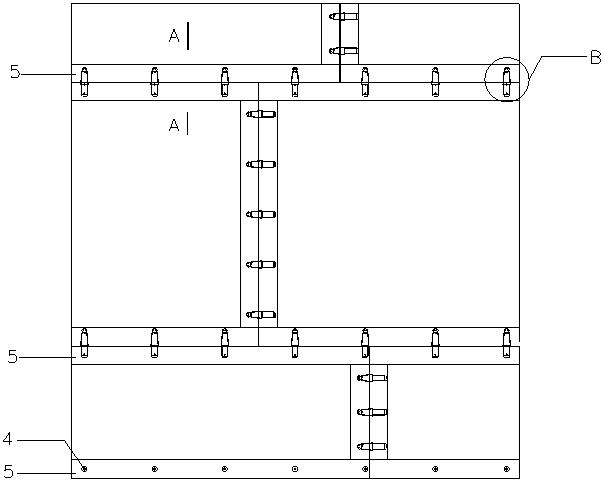

[0035] The FRP membrane shell of this implementation is as follows figure 1 As shown, it is a cylindrical structure composed of several prefabricated FRP segments 1 spliced by connecting buckles 6 on aluminum alloy hoops 5 at the edges of the segments. Resin in fiber cloth and mesh.

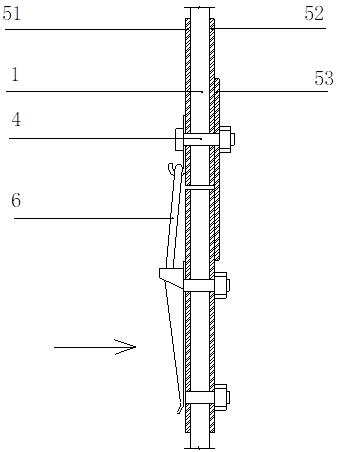

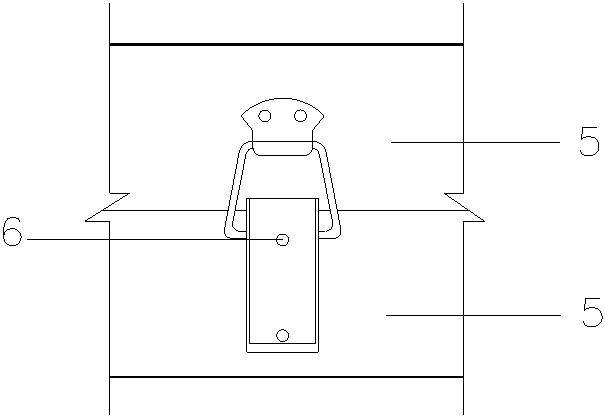

[0036] Structures at Connected Nodes figure 2 As shown, the bolts 4 are arranged on the edge of the FRP segment to sequentially connect the outer reinforcement plate 51, the inner reinforcement plate 52 and the inserting plate 53. When the connecting buckle 6 connects the adjacent segment from the outside, the inserting plate 53 is provided internally. Guidance and restraint. The structure of the quick connect buckle 6 is as follows image 3 As shown, direct purchase of existing clamp hasp / self-locking latch.

[0037] Such as Figure 4 As shown, the limit device includes a steel hoop 7 and a limit steel bar 8. The hoop 7 can be a Huff structure connected by bolts 4, or a buckle connection...

Embodiment 2

[0040] The FRP membrane shell of this implementation is as follows figure 1 and figure 2 As shown, it includes several semicircular FRP segments 1, with embedded metal interlayers on the edge of the FRP segments, and arranges longitudinal bolt holes and circumferential bolt holes that run through the FRP segments and metal interlayers; a pair of semicircular The FRP segment is connected end to end through the longitudinal connecting plate 2 to form an annular reinforced shell, and the bottom and top of several annular reinforced shells are fixedly connected and extended through the annular connecting plate 2;

[0041] There are two groups of longitudinal connection holes on the longitudinal connection plate 2, and each group of longitudinal connection holes corresponds to a longitudinal bolt hole on a semicircular FRP segment;

[0042] There are two sets of circumferential connecting holes on the circumferential connecting plate 3 , and each set of circumferential connecting...

Embodiment 3

[0046] The FRP membrane shell is made of mesh and fiber cloth. The type of fiber cloth can be glass fiber, carbon fiber or basalt fiber, etc. Taking basalt fiber cloth as an example, the tensile strength of basalt fiber cloth is 2300MPa, the modulus of elasticity is 80GPa, and the elongation is 2.7%. Define a section of BFRP membrane shell as a unit, the diameter can be designed according to the needs, and it is made of BFRP cloth and epoxy resin. The skeleton inside the membrane shell adopts BFRP fiber mesh. Bolt connection is used in the longitudinal direction. In order to avoid damage to the BFRP where the bolts are tightened, local reinforcement is required. During the manufacturing process of the membrane shell, a stainless steel sheet of the same size as the external metal plate is pre-embedded at the joint where it is required (the membrane shell is embedded in the membrane shell. Stainless steel interlayer), and the external metal plate and stainless steel sheet are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com