Method, device and system for predicting, evaluating and optimizing cement clinker performance

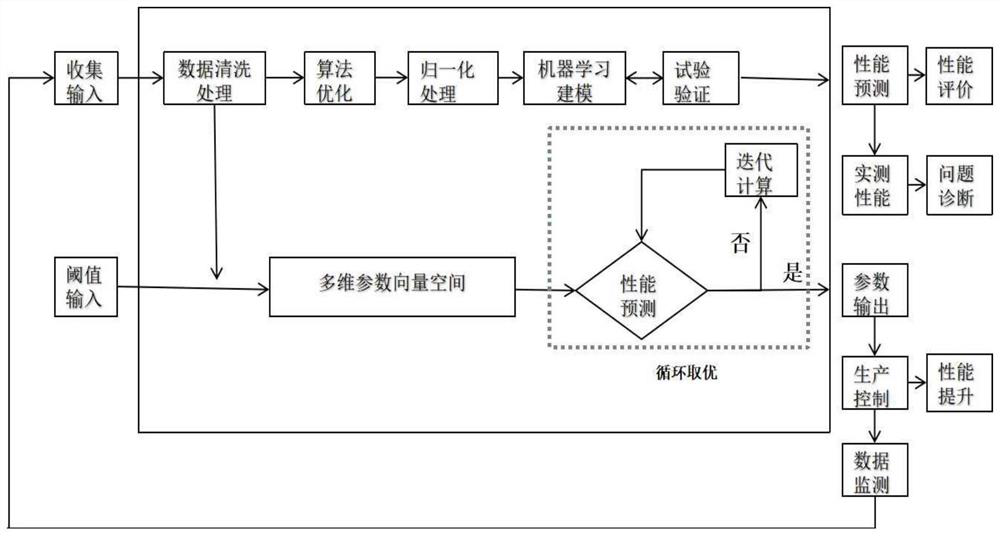

A cement clinker and performance prediction technology, applied in prediction, neural learning methods, character and pattern recognition, etc., can solve problems such as limited quality control, lack of reliability and accuracy, and failure to achieve stable optimization and improvement, and achieve Reduce cement production cost and production energy consumption, enhance product market competitiveness, and reduce the effect of optimization cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

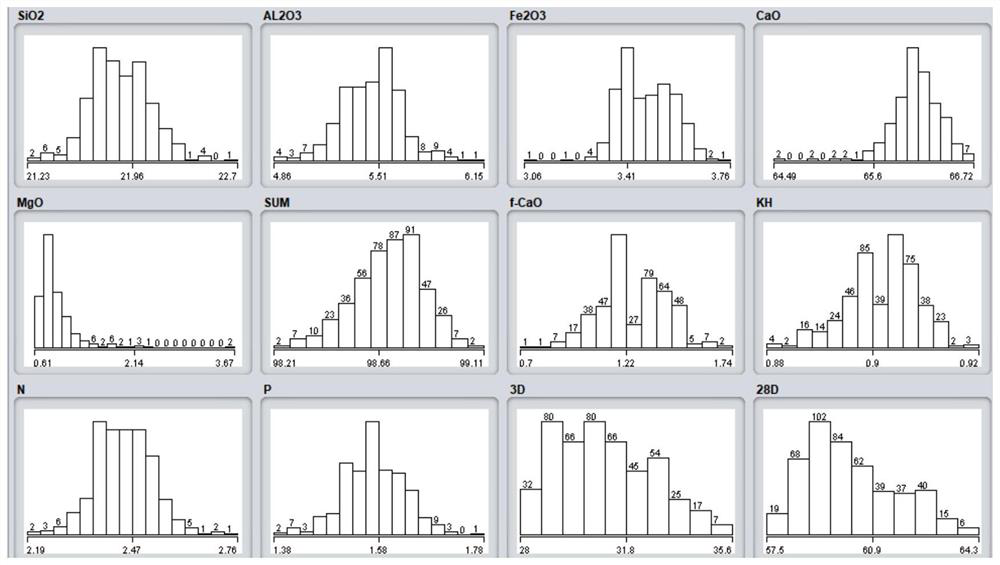

[0136] 500 sets of production data were collected in A cement plant, including chemical composition, free calcium oxide f-CaO content, clinker three-rate value, 3-day and 28-day strength and other complete sets of data information. Clean the data, remove the data with missing experimental values, discard the data that cannot be perfected, and sort out and obtain 472 sets of effective cement clinker production data samples. See figure 2 . According to the calculation relationship between the rate value and the chemical composition, data dimensionality reduction is carried out. After selecting the clinker rate value and CaO, SiO 2 、Al 2 o 3 and Fe 2 o 3 Only one of the four main components needs to be determined, and the other three can be determined, so three of the chemical composition variables can be deleted.

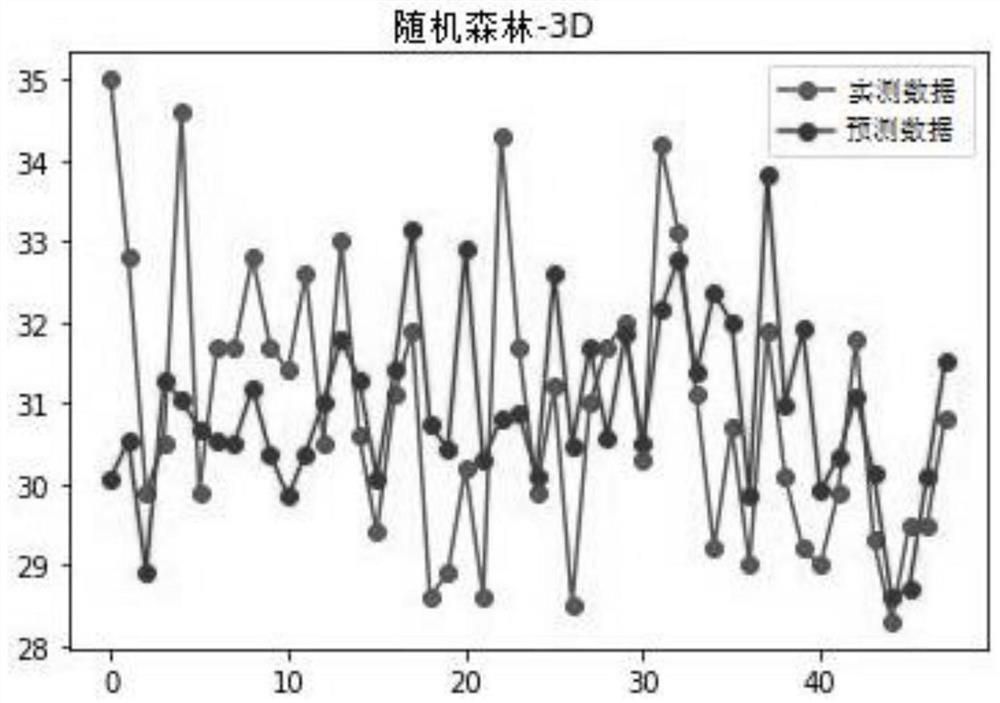

[0137] In this embodiment, the clinker rate value and CaO are selected as characteristic variables, and SiO is deleted. 2 、Al 2 o 3 and Fe 2 o 3 Compositi...

Embodiment 2

[0143] The performance prediction model formed by using the cement production process data obtained in Example 1 above can not only predict the strength performance of clinker, but also can be used to guide and optimize the production process and improve the clinker firing quality. The unsupervised learning method was used to analyze the distribution relationship and characteristics of the 3-day and 28-day strength, chemical composition and rate value of 472 groups of clinker samples, and the structure-activity relationship between each parameter variable and performance was obtained. According to the analysis results, for the data of the cement plant, the cement clinker with excellent 3-day and 28-day strength properties can be prepared by appropriately reducing the silicon rate N and increasing the aluminum rate P, such as Figure 5 to Figure 9 As shown, the relationship diagram of silicon rate and 3-day strength, the relationship diagram of silicon rate and 28-day strength, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com