Voltage-controlled magnetic impedance transformer

An impedance converter and magnetic technology, applied in waveguide devices, electrical components, connecting devices, etc., can solve the problems of difficult application, large volume of impedance adjuster, and low impedance adjustment accuracy, so as to achieve simple control algorithm and improve the overall efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

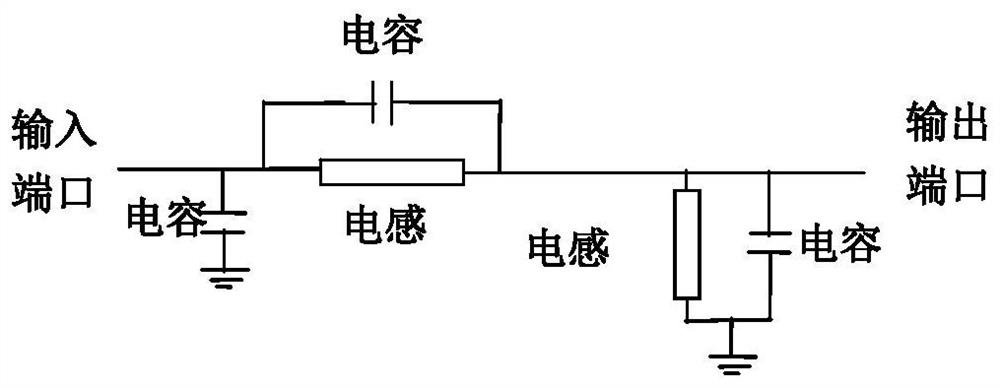

[0055] The embodiment discloses a voltage-controlled magneto-impedance converter, which includes a layer of magnetic medium layer, two sides of the magnetic medium layer are respectively connected to microwave transmission lines, and two microwaves are coupled to each other from the transmission lines. The direction of the magnetic field of the magnetic medium layer is perpendicular to the direction of the electromagnetic field of the microwave signal or rotated by an angle between 0° and 90°. The magnetic medium layer is connected to the voltage-controlled electrode through the ohmic contact layer, and the magnetic field strength or magnetic field direction of the magnetic medium layer is controlled by applying a voltage on the voltage-controlled electrode, so as to control the impedance transformation value, attenuation, phase shift, and conversion frequency point, and then realize the voltage control tuning.

[0056] The microwave transmission line is closely attached to th...

Embodiment 2

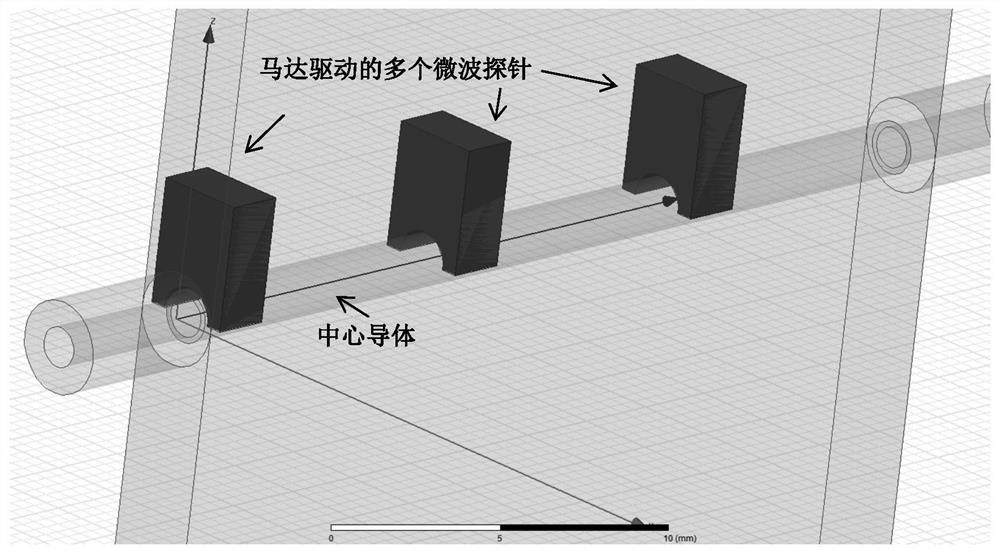

[0059] This embodiment discloses a voltage-controlled magneto-impedance transformer, which has substantially the same structure as Embodiment 1, the only difference being that the voltage-controlled magneto-impedance transformer of this embodiment is additionally designed with a metal transmission line. Metal transmission line and microwave transmission line coupling design. In some embodiments, an intermediate metal layer is designed between the magnetic medium layer and the microwave transmission line on one side, and the metal transmission line is disposed on the intermediate metal layer. In other embodiments, a groove is etched in the magnetic medium layer, and the metal transmission line is embedded in the groove. The design of the metal transmission line can further optimize the impedance transformation range, insertion loss and bandwidth.

Embodiment 3

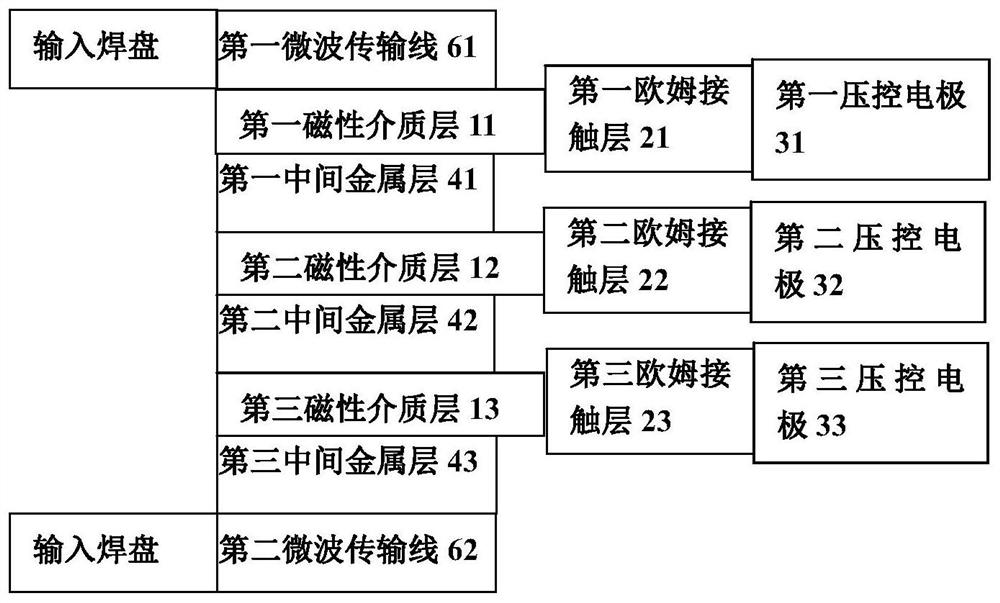

[0061] This embodiment discloses a voltage-controlled magneto-impedance converter, which includes multi-layer (at least two) magnetic medium layers and microwave transmission lines. The magnetic medium layer and the intermediate metal layer are alternately stacked layer by layer to form a multi-layer structure. Of course, it can also be Instead of alternately stacking layers one by one, for example, at least one intermediate metal layer may be provided at one or more places between the magnetic medium layer and the microwave transmission line, or between adjacent magnetic medium layers. Taking the layer-by-layer stacking structure as an example, the middle metal layer and the magnetic medium layer can be designed in equal quantities. The middle metal layer can be plate-shaped or other structures. The magnetic medium layer near the end and the metal layer of the middle piece are respectively connected to microwave transmission lines, and each microwave transmission line is resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com