Production equipment and production method of sucrose-6-ester

A technology for production equipment and equipment, which is applied in the preparation of sugar derivatives, separation methods, sugar derivatives, etc., can solve the problems of increasing production cost and energy consumption, reducing production efficiency, increasing production cycle, etc., so as to shorten production cycle and improve production efficiency. The effect of production efficiency and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

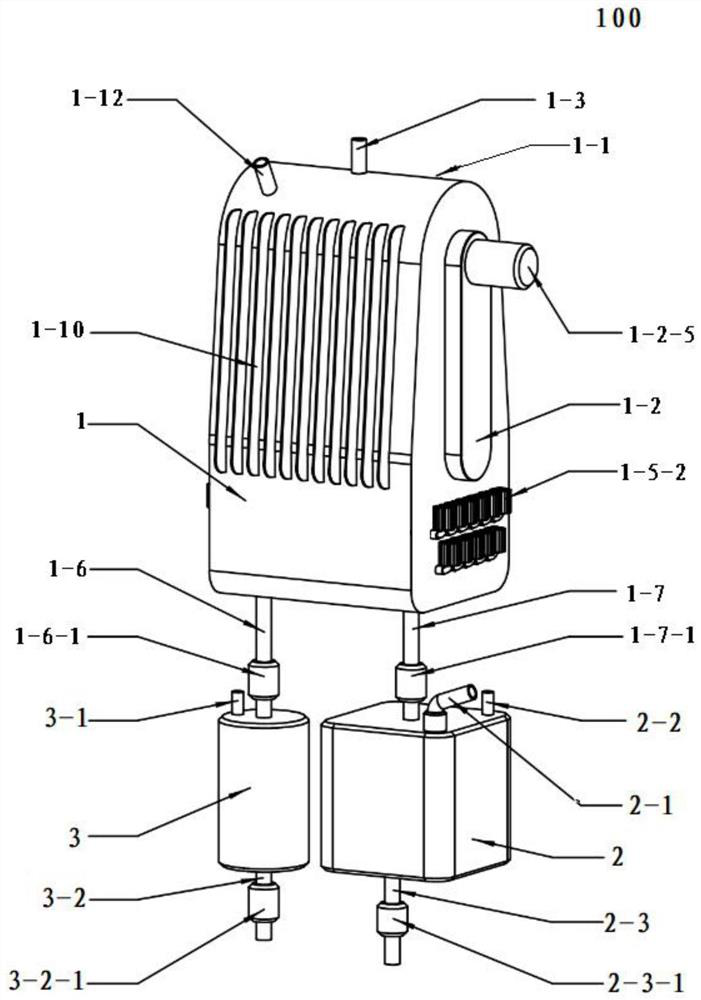

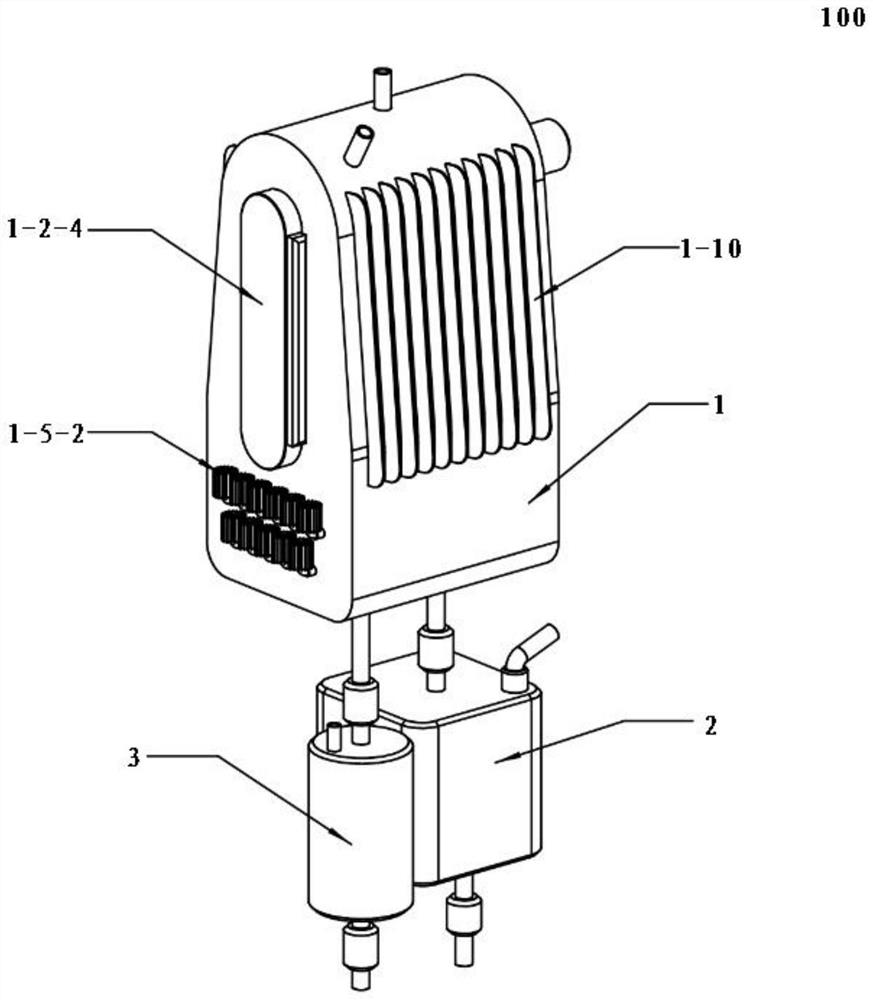

[0097] According to the mass ratio of sucrose, organotin ester accelerator (1,1,3-diacetoxy-1,1,3,3-tetrabutyldistannoxane), aprotic polar solvent (DMF) is 1 :2:10 configured into 300 kg of reaction solution.

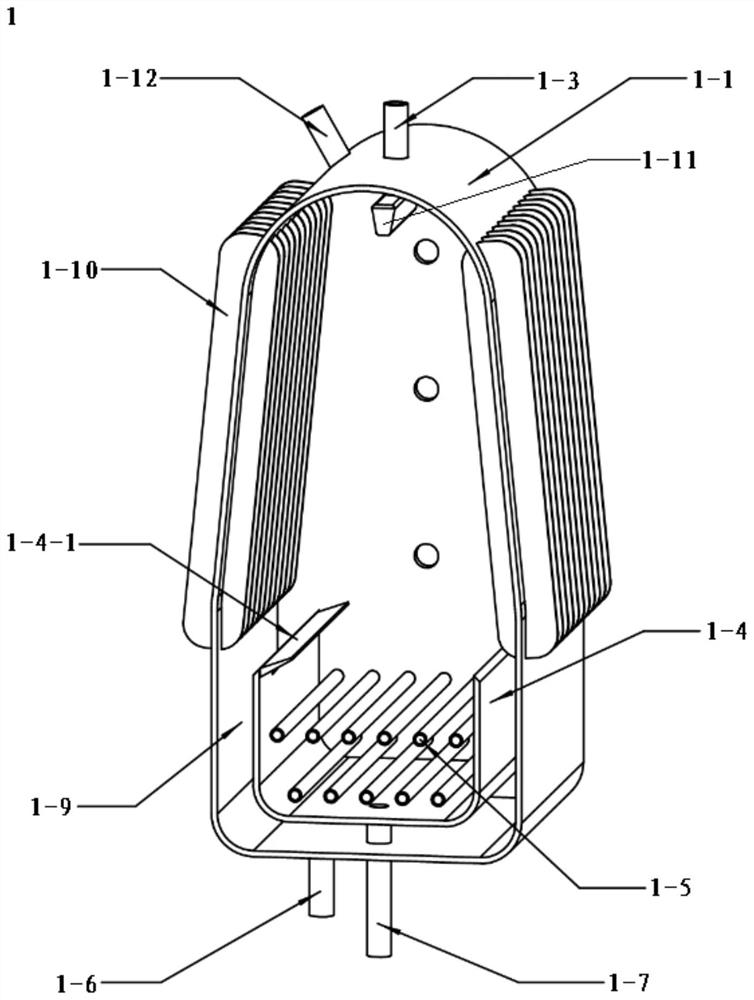

[0098] The production equipment of the sucrose-6-ester adopted by the present application generates the sucrose-6-ester, start the hot roll distillation device, set the temperature of each heating roll to 80°C, and set the speed of the heating roll to 0.1rad / s. The prepared reaction liquid was in 4m 3 The rate of / h is continuously fed into the above-mentioned production equipment, and the negative pressure of the reaction equipment is kept at 0.5kPa, and each valve is set to a corresponding state.

[0099] When the temperature of the inner chamber formed by the U-shaped plate reaches 15°C and the liquid level of the distillate reaches a preset value, the first electromagnetic valve is opened to start the esterification reaction under preset conditions.

[0100] At th...

Embodiment 2

[0106] According to the mass ratio of sucrose, organotin ester accelerator (1,1,3-diacetoxy-1,1,3,3-tetrabutyldistannoxane), aprotic polar solvent (DMF) is 1 :2:10 configured into 500 kg of reaction solution.

[0107] The sucrose-6-ester production equipment of the present application is used to generate sucrose-6-ester, start the hot roll distillation device, set the temperature of the first heating roll to 80°C, set the temperature of the second heating roll to 70°C, and set the temperature of the second heating roll to 70°C. The temperature of the three heating rollers is set to 60°C, and the speed of the heating rollers is set to 0.5rad / s. 3 The rate of / h is continuously fed into the above-mentioned production equipment, and the negative pressure of the reaction equipment is kept at 0.8kPa, and each valve is set to a corresponding state.

[0108] When the temperature of the inner cavity formed by the U-shaped plate reaches 10° C. and the liquid level of the distillate re...

Embodiment 3

[0115] According to the mass ratio of sucrose, organotin ester accelerator (1,1,3-diacetoxy-1,1,3,3-tetrabutyldistannoxane), aprotic polar solvent (DMF) is 1 :2:10 configured into 800 kg of reaction solution.

[0116] The sucrose-6-ester production equipment of the present application is used to generate sucrose-6-ester, start the hot roll distillation device, set the temperature of the first heating roll to 90°C, set the temperature of the second heating roll to 70°C, and set the temperature of the second heating roll to 70°C. The temperature of the three heating rollers is set to 60°C, and the speed of the heating rollers is set to 0.3rad / s. 3 The rate of / h is continuously fed into the above-mentioned production equipment, and the negative pressure of the reaction equipment is kept at 1.0kPa, and each valve is set to a corresponding state.

[0117] The temperature of the inner cavity formed by the U-shaped plate reaches 20° C., and the esterification reaction proceeds.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com