Preparation of an odorless amido dithiocarbonate compound and its application in flotation

An amido dithiocarbonate compound and the technology of amido dithiocarbonate, which are applied in the field of odorless xanthate and its preparation, can solve the problems of environmental pollution in xanthate production plants and mineral processing plants, and achieve The effect of shortening the production cycle, high product yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

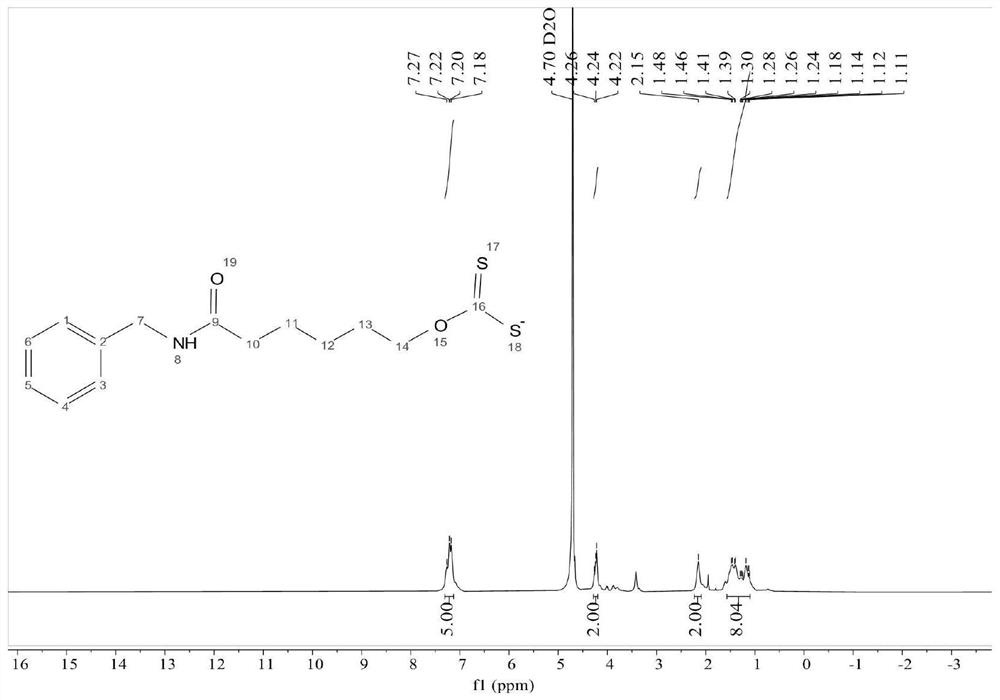

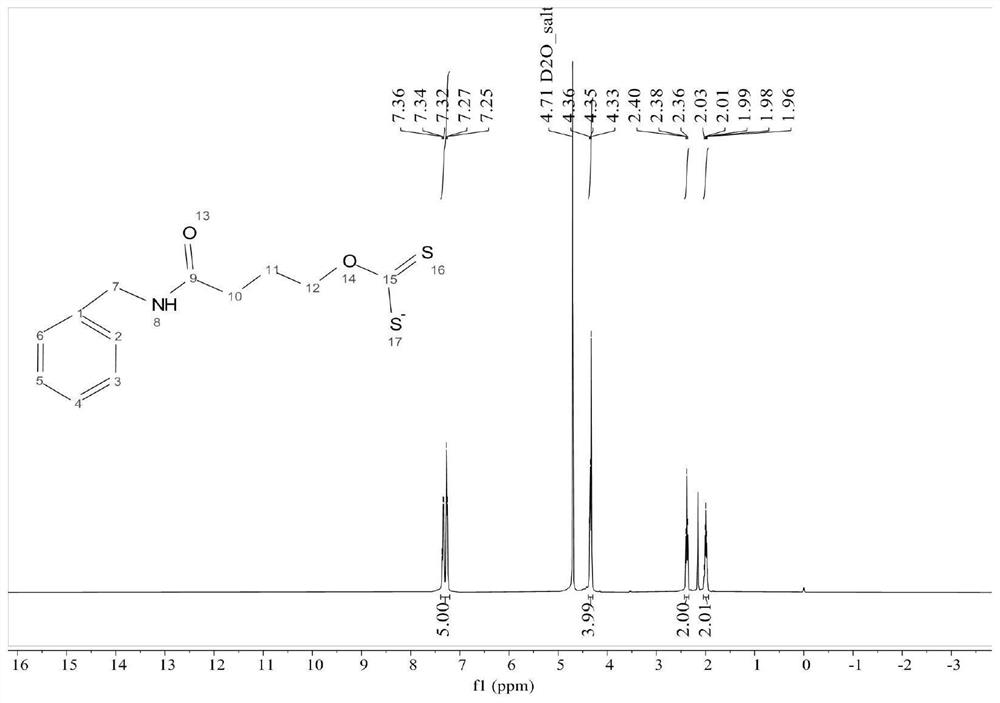

[0060] Embodiment 1: O-(2-benzamidoethyl)potassium dithiocarbonate preparation of

[0061] Add 17.21 parts of N-hydroxyethylbenzamide and 9.43 parts of distilled water into a three-necked flask, stir to dissolve the alcohol, then add 7.99 parts of carbon disulfide, and add a total of 6.60 parts of flake potassium hydroxide (85 %), after all was added, the stirring was continued for 30 minutes below 20°C, and then the temperature was raised to 30°C for 2.5h. 7.12 parts of solid xanthate with a purity of 98.30% and 34.11 parts of liquid xanthate with a purity of 59.2% were obtained. The total yield is 97.5%.

[0062] Note: The solid or liquid state of the product is caused by the amount of water content. When the water content is large, the product is a liquid aqueous solution; when the water content is slightly small, some products crystallize and can be separated by filtration to obtain solid products and liquid products; when the water content is further reduced, The xant...

Embodiment 2

[0063] Embodiment 2: Mother liquor circulation method prepares O-(2-benzamidoethyl) potassium dithiocarbonate

[0064] The first cycle: add 34.11 parts of liquid xanthate obtained in Example 1 into the reaction vessel, and simultaneously add 17.21 parts of N-hydroxyethylbenzamide, stir to dissolve the alcohol, then add 7.99 parts of carbon disulfide, and add in three batches 6. 60 parts (85%) of KOH in flake form. After the addition was complete, the mixture was stirred at a temperature below 20°C for 30 minutes, and then the temperature was raised to 30°C for 2.5 hours. 24.45 parts of solid xanthate with a purity of 96.00% and 41.46 parts of liquid xanthate with a purity of 55.8% were obtained, with a total yield of 94.7%.

[0065] The second circulation: 41.46 parts of liquid xanthates obtained in the previous step are added in the reaction vessel, then add 0.56 parts of distilled water and 17.21 parts of N-hydroxyethyl benzamide, stir to make it dissolve, then add 7.99 par...

Embodiment 3

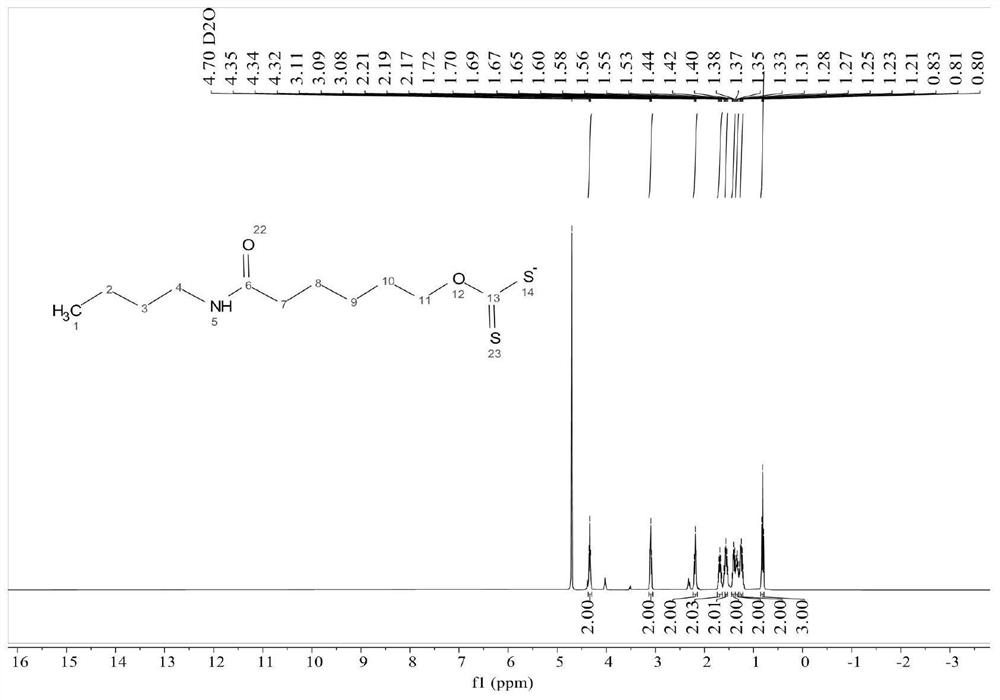

[0067] Embodiment 3: O-(2-acetamidoethyl)potassium dithiocarbonate preparation of

[0068] Add 10.74 parts of N-hydroxyethylacetamide and 15.45 parts of distilled water into a three-necked flask, then add 7.99 parts of carbon disulfide, and add a total of 6.60 parts of flaky potassium hydroxide (85%) in three batches below 20°C. , Stirring was continued below 20°C for 30 minutes, and then the temperature was raised to 30°C for 2.5h. 40.76 parts of liquid xanthate with a purity of 50.58% were obtained, and the yield was 94.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com