Intelligent management monitoring system and method for production of fixed spot welding machine

An intelligent management and monitoring system technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problem of not being able to check the production quantity of nuts/bolts used, etc., to avoid the risk of missing welding, avoid resource waste, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

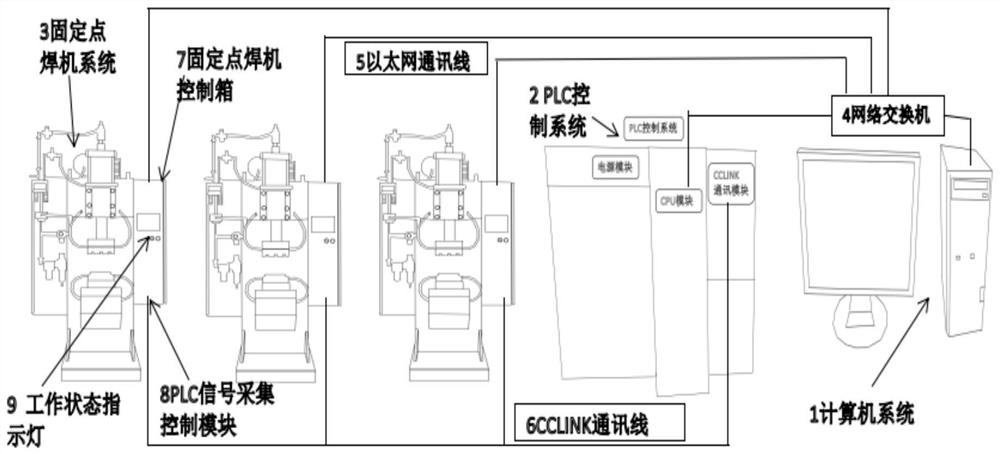

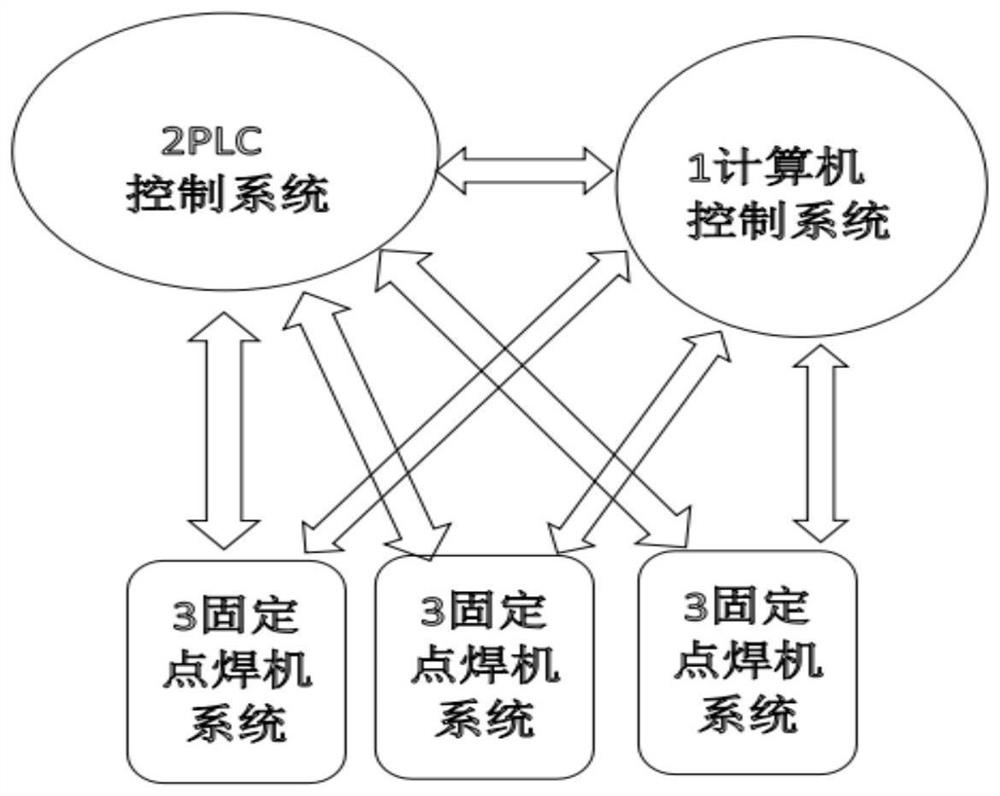

[0042] The present invention will be further described below with reference to the examples:

[0043] The present invention is further detailed in conjunction with the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are merely illustrative of the invention and are not limited thereto. It will also be noted that in order to facilitate the description, only the parts associated with the present invention are shown in the drawings rather than all structures.

[0044] It should be noted that similar reference numerals and letters represent the like items in the drawings below, and therefore, once one is defined in one bysertation, it is not necessary to further define and explain it in the following drawings. Meanwhile, in the description of the present invention, the term "first", "second", etc., only for distinguishing description, and cannot be understood as an instruction or implied relative importance.

[0045] Such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com