Low-loss low-temperature co-fired ceramic green tape and preparation method thereof

A low-temperature co-fired ceramic, low-loss technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problem of yellowing on the edge of Ag conductors, poor control of sintering temperature, and mismatch between LTCC materials and sintered conductors Good and other problems, to achieve the effect of easy sintering matching, control of silver diffusion, and wide sintering window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

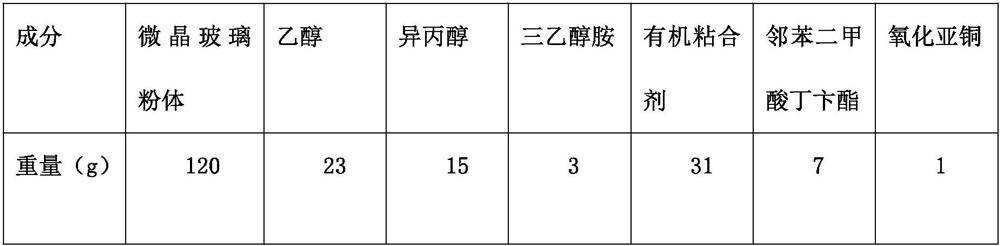

Embodiment 1

[0035] A low-loss low-temperature co-fired ceramic green belt of the present invention is composed of glass-ceramic powder, subvalent oxide, solvent, organic resin, dispersant and plasticizer.

[0036] Further, the glass-ceramic powder is composed of glass-ceramic powder A and glass-ceramic powder B;

[0037] Further the massfraction of each component of glass-ceramic powder A is:

[0038] 42wt% CaO, 30wt% B2O3, 25wt% SiO2, 1.5wt% P205, 1.0wt% K20, 0.5wt% Na20

[0039] The mass fraction of each component of glass-ceramic powder B is:

[0040] 36wt% CaO, 12wt% B2O3, 50wt% SiO2, 1.5wt% Al2O3, 0.5wt% MgO

[0041] Glass-ceramic powder A and B preparation method are as follows:

[0042] Glass-ceramic powder A, weigh the components in proportion and mix them evenly, place them in a platinum crucible, put the platinum crucible in a high-temperature glass melting furnace, keep it warm at 1400°C for 1 hour, then pour the molten glass into Quenching in deionized water to form glass ...

Embodiment 2

[0049] The present embodiment glass-ceramic powder A and B are identical with embodiment 1, but the glass-ceramic powder body is mixed by 35wt% A and 65wt% 55B, other composition is by the same ratio of embodiment 1.

Embodiment 3

[0051] The low-loss low-temperature co-fired ceramic green tape of this embodiment is composed of glass-ceramic powder, subvalent oxide, solvent, organic resin, dispersant, and plasticizer.

[0052] Further, the glass-ceramic powder is composed of glass-ceramic powder A and glass-ceramic powder B;

[0053] Further the massfraction of each component of glass-ceramic powder A is:

[0054] 40wt% CaO, 36wt% B2O3, 22wt% SiO2, 1.0wt% P2O5, 0.5wt% K2O, 0.5wt% Na2O

[0055] The mass fraction of each component of glass-ceramic powder B is:

[0056] 40wt% CaO, 15wt% B2O3, 43wt% SiO2, 1.5wt% Al2O3, 0.5wt% MgO

[0057] Glass-ceramic powder A and B preparation method are as follows:

[0058] Glass-ceramic powder A, weigh the components in proportion and mix them evenly, place them in a platinum crucible, put the platinum crucible in a high-temperature glass melting furnace, keep it warm at 1400°C for 1 hour, then pour the molten glass into Quenching in deionized water to form glass sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com