A multi-water layer four-dispersion foaming agent for natural gas horizontal wells

A technology of foaming agent and horizontal well, applied in the direction of wellbore/well components, drilling composition, production fluid, etc. It can solve the problems of large foam drainage and gas recovery method, undiscovered sweeping range, etc., and achieve foaming ability Strong, wide-reaching, and noticeable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

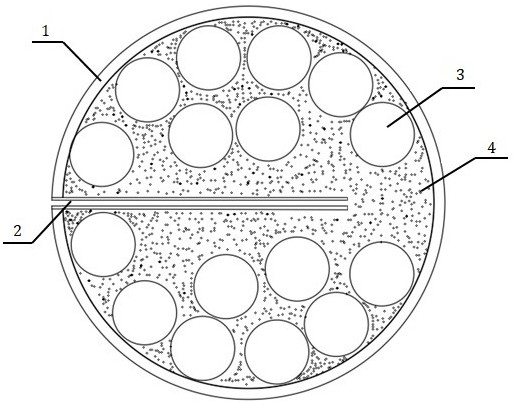

[0012] The present invention will be further described in conjunction with accompanying drawings.

[0013] refer to figure 1 . The multi-water layer scattered foam release agent for natural gas horizontal wells is composed of a foam release agent spherical shell 1, a water channel 2, an inner foam release agent ball 3, and fast foaming particles 4. The inner foam depletion agent ball 3 and the fast foaming particles 4 are filled with the foam depletion agent spherical shell 1. The foam discharge agent spherical shell 1 and the inner foam discharge small ball 3 are composed of the following components in mass percentage, 35% of sodium dodecylsulfonate, 27% of fatty alcohol polyoxyethylene ether, 10% of acrylic resin, and 8% of sodium bicarbonate %, urea 5%, citric acid 15%. The fast-foaming granule is composed of the following components in mass percentage, 35% of sodium carbonate / sodium bicarbonate (1:9), 50% of citric acid, and 15% of 5% polyethylene glycol.

[0014] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com