Method for pre-judging gelatin viscosity in gelatin production and application thereof

A production method and technology of gelatin, which is applied in the field of gelatin enzymatic production of gelatin, can solve the problems of uncontrollable viscosity, uncontrollable viscosity, and inability to improve product grades, etc., and achieve the effects of convenient analysis of viscosity, protection of viscosity, and reduction of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for measuring the viscosity in the method for rapidly predicting gelatin viscosity in advance of the present invention in gelatin production is as follows:

[0030] The viscosity of the glue solution in the gelatin production process is detected, and concrete operation is to get the dilute glue solution 80ml in the gelatin production process with conical flask, add purified water and be mixed with the dilute glue solution that concentration is 2% (through analysis, production link glue The liquid concentration is basically in the range of 2%-5%, and most of the glue concentration is close to 2%. In order to detect all links, the preparation concentration is set to 2% for research), and the Erlenmeyer flask is placed at 60°C Heat it in a constant temperature water bath to raise the temperature of the glue to 60°C. Start the Blaine viscometer, raise the temperature of the water in the glass water bath to 60±0.1°C, take out the conical flask, pour the glue solut...

Embodiment 2

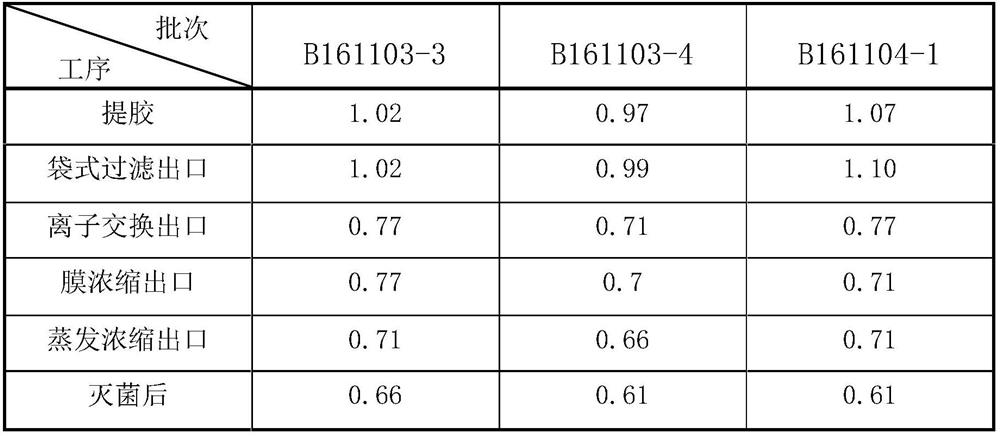

[0035] Application of the method according to Example 1 in actual production: In 2016, the applicant built a new gelatin production line. Its production process is as follows:

[0036] (1) Raw material processing: transport the qualified bone grains to the pulverizer, grind the bone grains into powder, and then sieve the powder from the pulverizer to obtain bone meal;

[0037] (2) Pickling: Add the bone powder prepared in step (1) into a pickling tank for pickling to obtain bone bone. The more specific pickling process is as follows: first add water to the pickling tank, then stir while adding bone meal, after fully stirring, add the prepared acid solution and continue stirring fully, and finally perform centrifugation to obtain bone bone;

[0038] (3) Gel extraction: after the osteoin prepared in step (2) is washed with water, the osteoin is transported to a gel extraction pot for gel extraction to obtain a primary glue solution. Its specific operation is to control the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com