Unconventional metasurface sparse aperture lens

A sparse aperture and metasurface technology, applied in lenses, instruments, optics, etc., can solve the problems of processing difficulty, increased processing time and material cost, and the inability of metasurface lenses to make large-aperture equipment, achieving small errors and phase differences. Accurate modulation, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

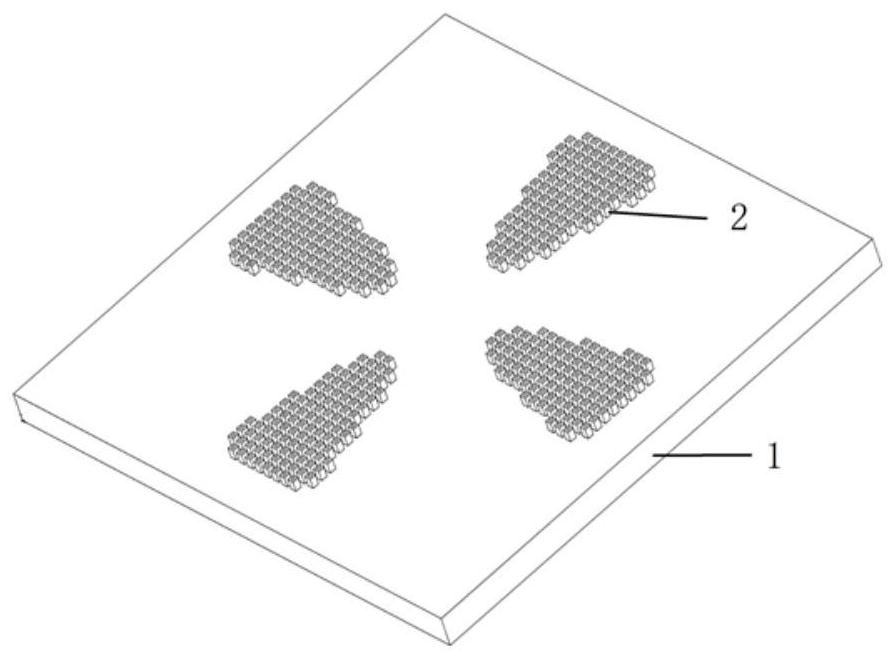

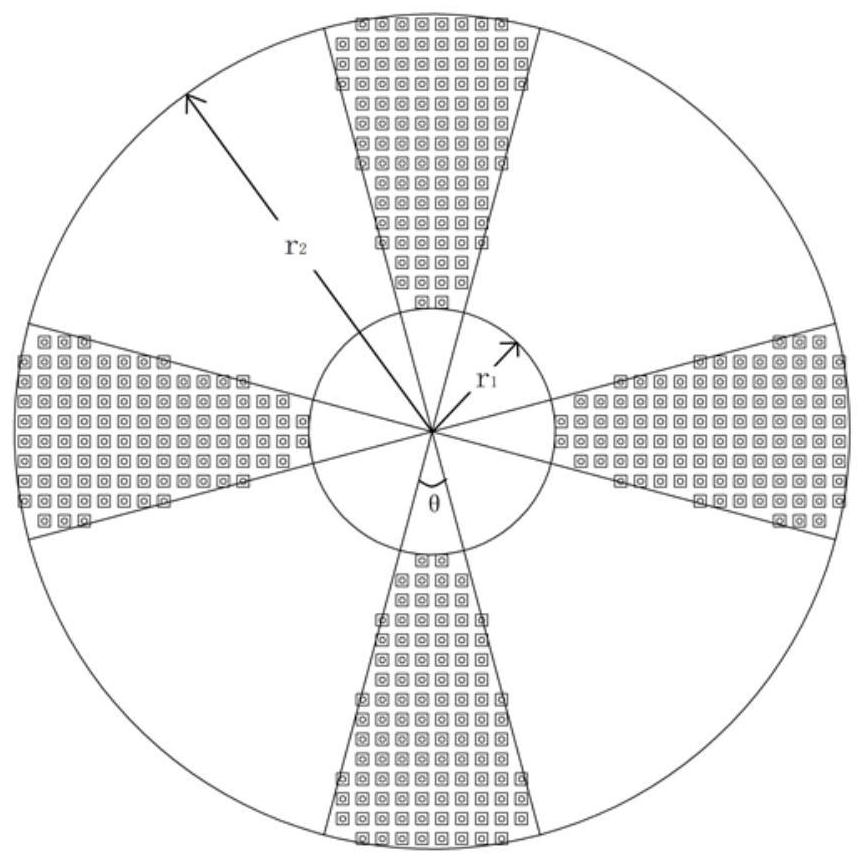

[0025] See figure 1 As shown, the metasurface circular sparse aperture of the present invention is composed of a light-transmitting substrate and a metasurface microstructure unit. The light-transmitting base material is silicon dioxide, and the structural unit material of the metasurface is silicon. The metasurface microstructure units constitute sub-apertures of sparse apertures in four concentric sector ring regions. The four fan rings are located in the same circle, and the radians and generatrices are equal, and the polar coordinate azimuth intervals are equal. They are respectively located in the directions of 0°, 90°, 180° and 270° of the center. The inner radius r1 of the fan ring is 50um, the outer radius r2 is 250um, and the opening angle is θ=30°.

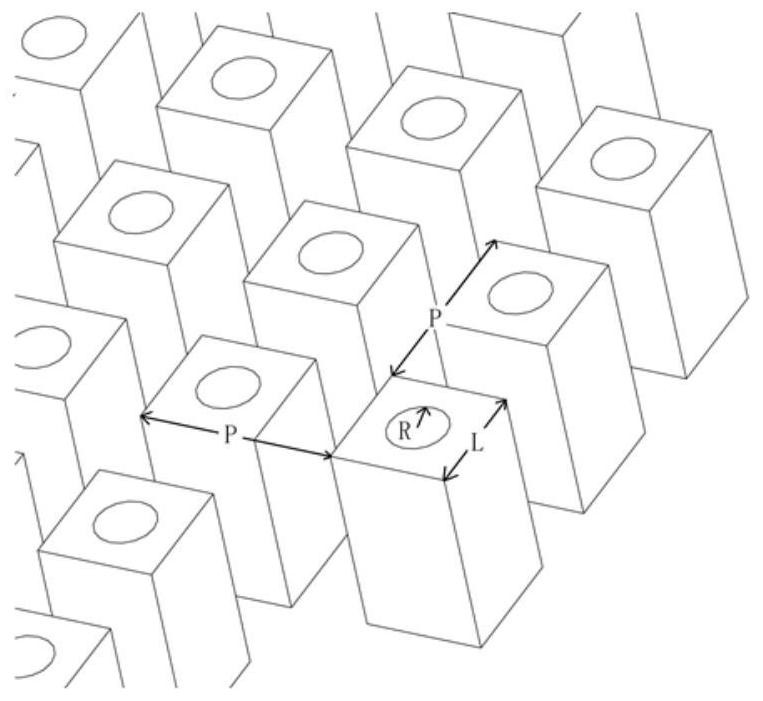

[0026] The metasurface microstructure unit is a hollow rectangular array, the side length of the rectangular array is L=0.3 μm, the period P=0.4 μm, and the height of the rectangle is H=0.7 μm. The hollow figure in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com