Calcium carbonate filled composite material design method based on BP neural network

A BP neural network and composite material technology, which is applied in neural learning methods, biological neural network models, computer-aided design, etc. Composite material structure and performance design and other issues, to achieve the effect of improving R&D efficiency and shortening the R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

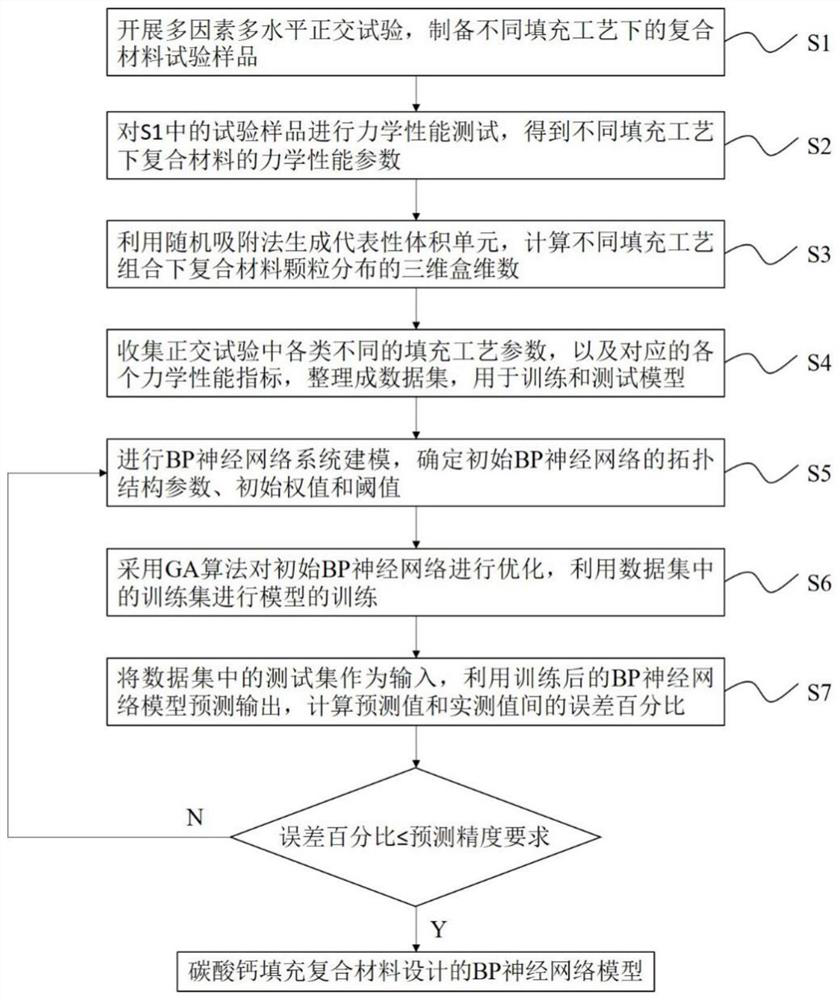

[0049] like figure 1 As shown, the design method of calcium carbonate filled composite material based on BP neural network in this embodiment includes the following steps:

[0050] Step S1: Design a multi-factor and multi-level orthogonal test, and prepare test samples

[0051] Table 1 Orthogonal test factor and level table

[0052]

[0053] Table 2 L9(3 3 ) test plan

[0054]

[0055] Operate according to the orthogonal test design scheme in Table 1 and Table 2. First, weigh 10kg of calcium carbonate with different particle sizes, then add an equal amount of surface modifier and mix thoroughly to form a layer of wrapping on the surface of the calcium carbonate particles. Then, the surface-modified calcium carbonate particles are added to the PVC matrix for mixing, placed in an ultrasonic oscillator or a high-speed mixer with a speed of not less than 3000 rpm, and stirred at a temperature of 100 ° C for 50 minutes to make Disperse uniformly, then cool down to below 4...

Embodiment 2

[0083] like figure 1 As shown, the method for predicting the mechanical properties of calcium carbonate filled composite materials based on reverse modeling in this embodiment includes the following steps:

[0084] Step S1: Design a multi-factor and multi-level orthogonal test, and prepare test samples

[0085] Operate according to the orthogonal test design scheme in Table 1 and Table 2. First, weigh 10kg of calcium carbonate with different particle sizes, then add an equal amount of surface modifier and mix thoroughly to form a layer of wrapping on the surface of the calcium carbonate particles. Then, the surface-modified calcium carbonate particles are added to the PP matrix for mixing, placed in an ultrasonic oscillator or a high-speed mixer with a speed of not less than 3000 rpm, and stirred at 120 ° C for 30 minutes to make Disperse uniformly, then cool down to below 40°C and discharge for later use; then add the above-mentioned ready-to-use mixture into the co-rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com