Method for improving quality of frozen and thawed fish meat based on high-voltage electric field

A high-voltage electric field and fish meat technology, which is applied to the preservation of meat/fish, meat/fish preservation through freezing/cooling, meat/fish preservation through radiation/electrical treatment, etc., can solve the problems of reducing product quality and achieve less water loss , enhanced safety, less damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

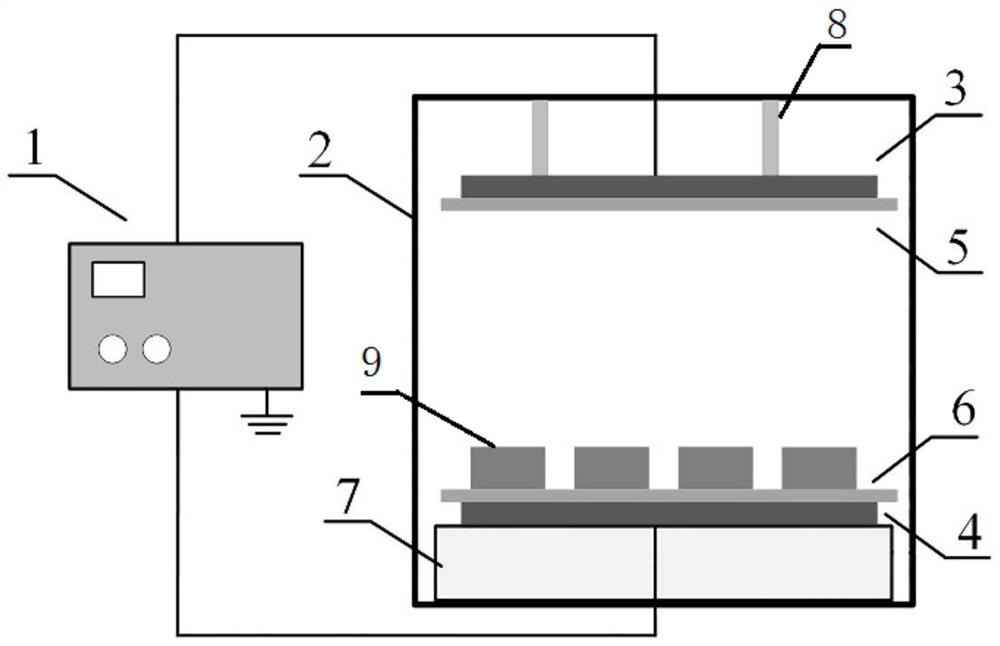

[0030] Such as figure 1 As shown, a high-voltage electric field assisted freezing device includes: a high-voltage output power supply 1 , a freezer 2 , a positive plate 3 , a negative plate 4 , a barrier plate 1 , a barrier plate 2 6 , a sample stage 7 and a telescopic rod 8 .

[0031] The high-voltage output power supply 1 is installed outside the freezer 2, and its output terminal and ground terminal are respectively connected to the positive plate 3 and the negative plate 4; the positive plate 3 and the negative plate 4 are respectively installed on both sides of the freezer, and the materials used are Food grade stainless steel.

[0032] The surface corresponding to the positive plate 3 and the negative plate 4 is also provided with a blocking separator, and the material is polytetrafluoroethylene with excellent insulation; the blocking separator is closely attached to the surface of the positive plate and the negative plate, and the length It is longer than the length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com