Oxide solid electrolyte and preparation method thereof

A technology of solid electrolyte and oxide, applied in the direction of electrolyte, non-aqueous electrolyte battery, circuit, etc., can solve the problems of high sintering temperature, increased energy consumption, reduced cost, disadvantages, etc., and achieve the effect of preventing electrolyte performance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] In the first aspect, the embodiment of the present application provides a method for preparing an oxide solid electrolyte. The oxide solid electrolyte is sintered and crystallized from a lithium salt precursor and a main material. The lithium salt precursor includes at least two kinds of lithium salts. A lithium salt eutectic system with a eutectic temperature of 100-450°C. The preparation method includes: sintering and crystallizing a mixture formed of a lithium salt precursor and a main material at a temperature of 300-750°C to obtain an oxide solid electrolyte.

[0019] The present application adopts a lithium salt eutectic system formed by at least two lithium salts with a eutectic temperature of 100-450°C as a lithium salt precursor, which can reduce the sintering temperature, sintering at a temperature of 300-750°C, and lithium salt eutectic The system and the main material are melted and reacted to form the primary oxide solid electrolyte, which crystallizes durin...

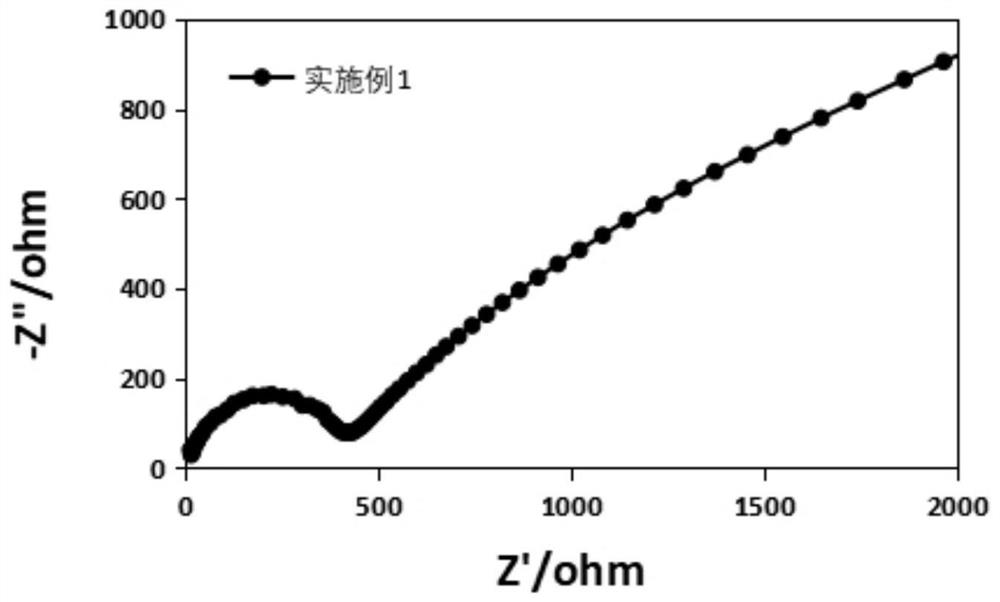

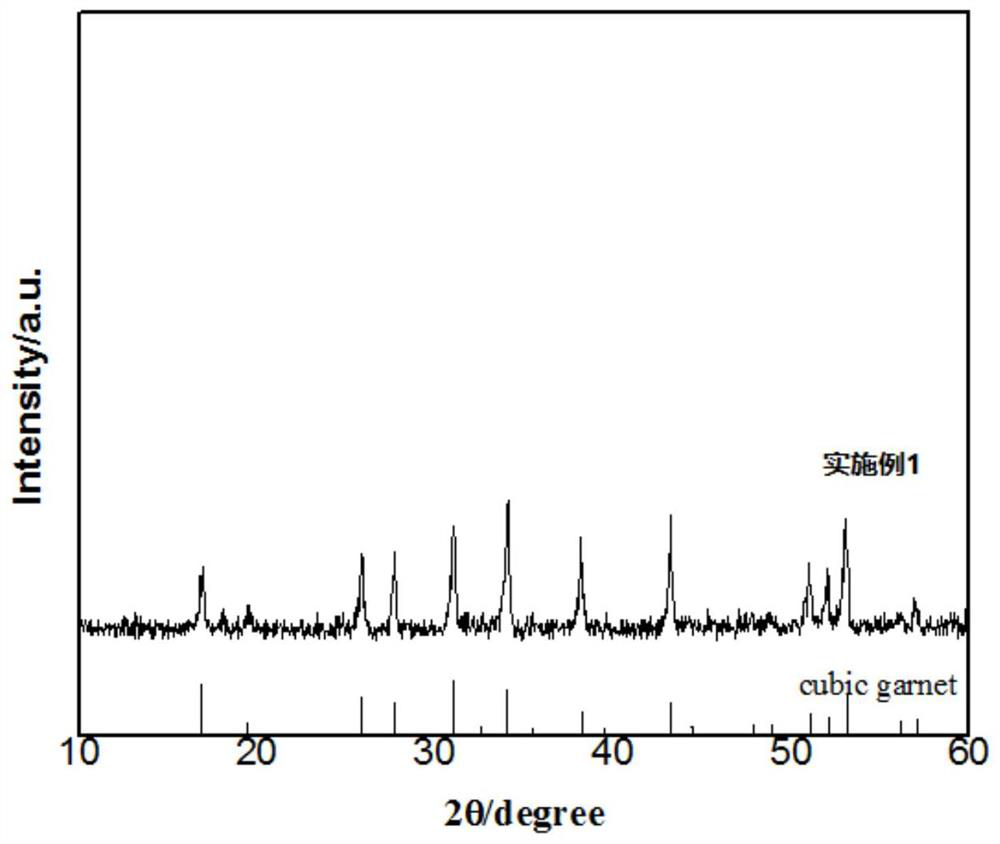

Embodiment 1

[0051] This embodiment provides a method for preparing an oxide solid electrolyte, which includes:

[0052] LiOH·H with a molar ratio of 0.38:0.62 2 O and LiNO 3 The lithium salt eutectic system is used as the lithium salt precursor, and the eutectic temperature of the lithium salt eutectic system is 175.7°C. Weigh 10.36g LiOH·H 2 O and 27.79g LiNO 3 Add in the ball mill jar, put 48.87g La 2 o 3 , 18.48g ZrO 2 and 11.05gTa 2 o 5 respectively added into the ball mill jar, and then added isopropanol for ball milling for 10 hours to obtain a mixed slurry.

[0053] Pour the mixed slurry into a beaker and blow dry at 90°C for 10 hours to obtain the mixture. Put the mixture into a sagger at a heating rate of 5°C / min to 400°C for heat treatment, and the holding time is 4 hours; after the heat treatment The temperature was raised to 750°C for sintering, and the holding time was 8h.

[0054] Annealing after sintering yields cubic Li 6.5 La 3 Zr 1.5 Ta 0.5 o 12 oxide soli...

Embodiment 2

[0056] This embodiment provides a method for preparing an oxide solid electrolyte, which includes:

[0057] LiNO with a molar ratio of 0.71:0.29 3 The lithium salt eutectic system with LiCl is used as the lithium salt precursor, and the eutectic temperature of the lithium salt eutectic system is 221.6°C. Weigh 31.8gLiNO 3 and 7.99gLiCl are added to the ball mill jar, and 48.87gLa 2 o 3 , 18.48g ZrO 2 and 11.05g Ta 2 o 5 respectively added into the ball mill jar, and then added isopropanol for ball milling for 10 hours to obtain a mixed slurry.

[0058] Pour the mixed slurry into a beaker and blow dry at 90°C for 10 hours to obtain the mixture. Put the mixture into a sagger at a heating rate of 5°C / min to 400°C for heat treatment, and the holding time is 6 hours; after the heat treatment The temperature is raised to 750°C for sintering, and the holding time is 10h.

[0059] Annealing after sintering yields cubic Li 6.5 La 3 Zr 1.5 Ta 0.5 o 12 oxide solid electrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com