Photovoltaic power generation physical reference control method

A technology for photovoltaic power generation and photovoltaic cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

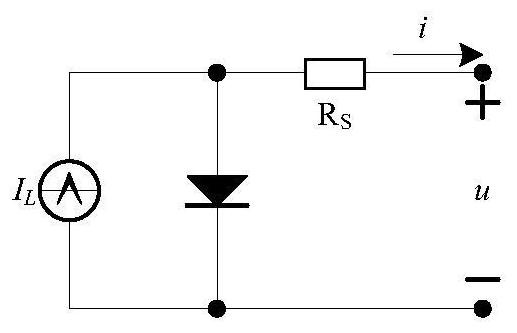

[0056] Photovoltaic power generation system with simple physical reference control

[0057] The photovoltaic power generation system with simple physical reference control is mainly composed of a working photovoltaic cell, two reference photovoltaic cells, a controller and a load, such as Figure 4 As shown, the working photovoltaic cell is connected to the energy input port of the controller, and the energy output port of the controller is connected to the load.

[0058] The reference photovoltaic cell adopts A and B two monolithic objects of the same quality as the working photovoltaic cell. Block A is used to measure the open circuit voltage, and block B is used to measure the short-circuit current. The reference photovoltaic cell is placed near the working photovoltaic cell. The reference photovoltaic cell Connect with the signal input port of the controller through the controlled source.

[0059] Measurement of the open circuit voltage of the reference photovoltaic cell ...

Embodiment 2

[0064] Photovoltaic power generation system with mean value physical reference control

[0065] The photovoltaic power generation system with reference to the fixed average measurement algorithm in kind is mainly composed of working photovoltaic cells, reference photovoltaic cells, controllers and loads, such as Figure 6 As shown, the working photovoltaic cell is connected to the energy input port of the controller, and the energy output port of the controller is connected to the load.

[0066] The reference photovoltaic cell adopts A, B, C, and D four pieces of monolithic objects of the same quality as the working photovoltaic cell. A block is used to measure the open circuit voltage, B block is used to measure the short circuit current, and C block is used to measure α = 80% open circuit The current at voltage and block D are used to measure the voltage at the time of β=80% short-circuit current. The reference photovoltaic cell is placed near the working photovoltaic cell, ...

Embodiment 3

[0074] Photovoltaic power generation system with scanning object reference control

[0075] The photovoltaic power generation system with scanning physical reference control is composed of working photovoltaic cells, reference photovoltaic cells, controllers and loads. The voltage scanning method is as follows: Figure 9a As shown, the current sweep method is as Figure 9b As shown, the working photovoltaic cell is connected to the energy input port of the controller, and the energy output port of the controller is connected to the load.

[0076] Voltage scanning method: the reference photovoltaic cell adopts A and C two single-chip objects of the same quality as the working photovoltaic cell, A block is used to measure the open circuit voltage, and C block is used to measure the current during voltage scanning, and the reference photovoltaic cell is placed on the working photovoltaic cell Nearby, the reference photovoltaic cell is connected to the signal input port of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com