Interconnected radial phase change micro-channel radiator

A micro-channel and radial technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of reducing the cooling efficiency and thermal uniformity of radiators, and the decline of fluid convective heat transfer, etc., to achieve Delayed boiling flow instability phenomenon, simple and clear micromachining and packaging process, and improved cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

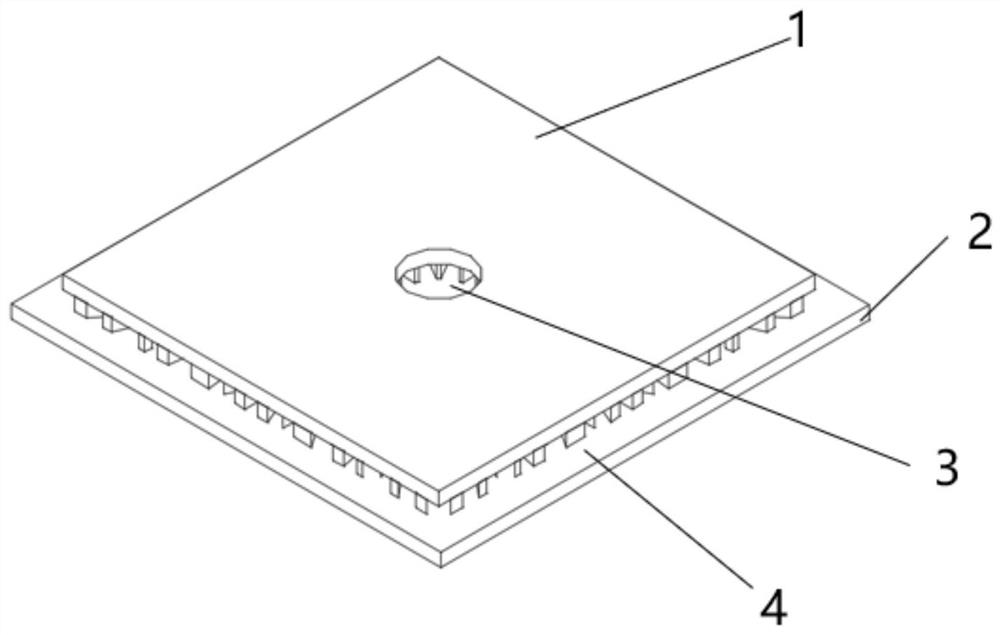

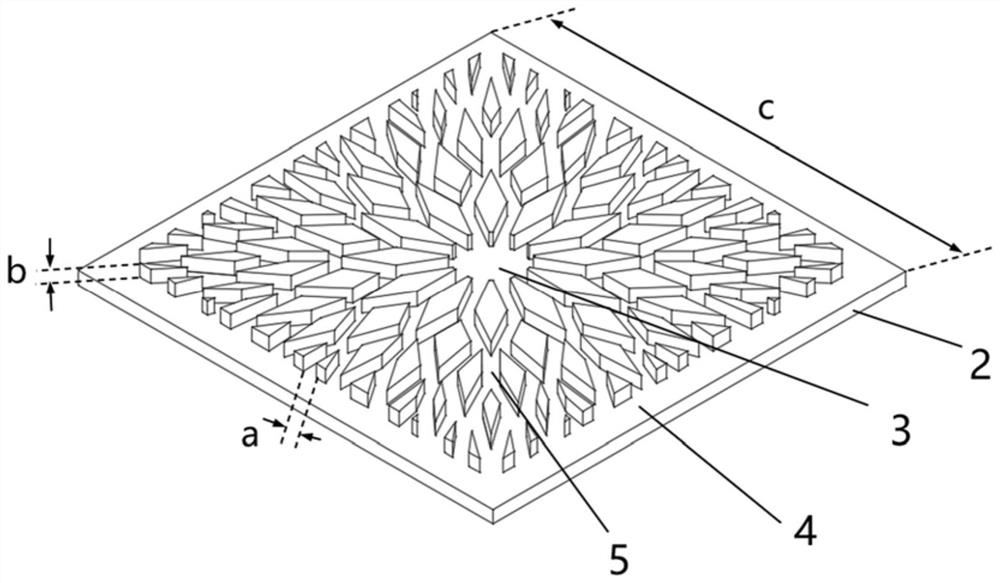

[0031] Such as figure 1 and figure 2 As shown, an interconnected radial phase-change microchannel radiator includes a chassis 2 and a cover plate 1 oppositely arranged. The cover plate 1 serves as a flow guide for the inlet and outlet of the cooling working fluid, and as a microchannel upper surface;

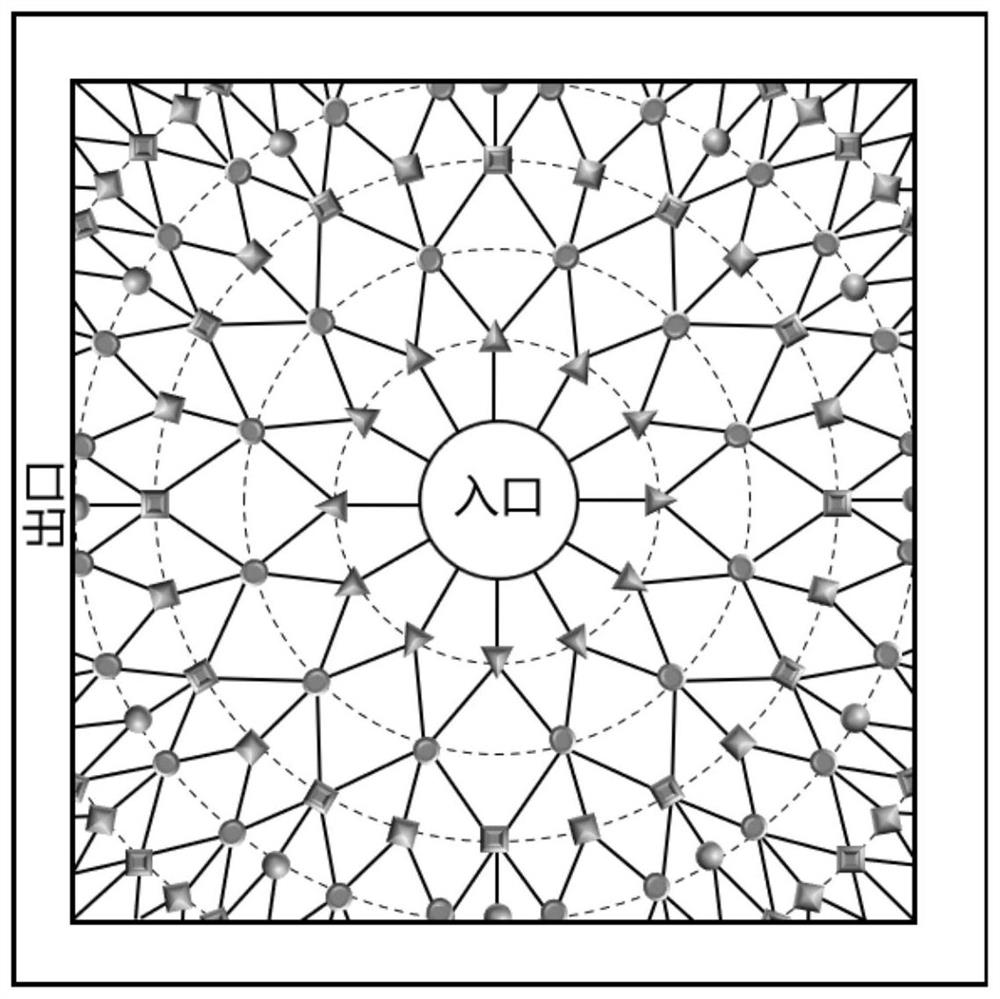

[0032] The chassis 2 is provided with a microchannel 5, and the microchannel 5 develops from the center of the chassis 2 to the periphery of the chassis 2 in an interconnected radial manner. The center of the cover plate 1 and the chassis 2 is provided with a cooling medium inlet 3, and the cover plate 1 and the chassis 2 The cooling medium outlet 4 is arranged at the edge of the chassis 2, and the chassis 2 transfers the heat of the cooling equipment to the cooling fluid, and the cooling fluid flows from the center of the chassis 2 to the surrounding edges of the chassis 2 along the direction of the microchannel 5, thereby taking away the heat.

[0033] Wherein, the cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com