2D magnetic fe 3 gete 2 Nanosheet and graphene nanosheet composite material and preparation method and application thereof

A technology of graphene nanosheets and composite materials, applied in the field of wave absorbing materials, can solve the problems of low thickness, unable to meet the reflection loss value at the same time, hinder the development of wave absorbing materials, etc., and achieve high power, good dispersion effect, high power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

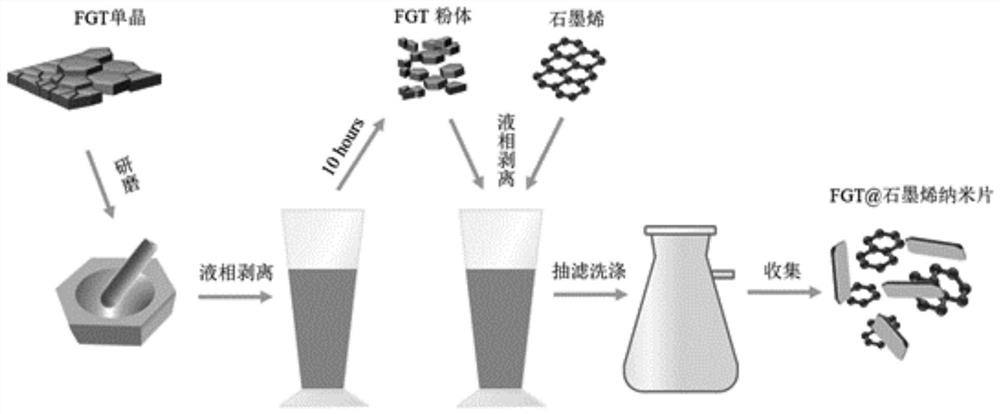

[0042] This embodiment provides a two-dimensional magnetic Fe 3 GeTe 2 Nanosheet and graphene nanosheet composite material, the process of its preparation method is as follows figure 1 It includes the following steps:

[0043] (1) Grinding Fe 3 GeTe 2 Single crystal, to obtain Fe 3 GeTe 2 powder; Fe 3 GeTe 2 The powder was added to acetone (1mg / mL), and the ultrasonic liquid phase exfoliation was carried out for 10 hours. The power of ultrasonic liquid phase exfoliation was 500W to obtain Fe. 3 GeTe 2 Nanosheet dispersion.

[0044] (2) Collect Fe by vacuum filtration and washing with deionized water 3 GeTe 2 Nanosheets, dried under vacuum to obtain Fe 3 GeTe 2 Nanosheets.

[0045] (3) Graphite and Fe 3 GeTe 2 The nanosheets were uniformly mixed in a mass ratio of 1:1 to 3, added to NMP (1-methyl-2-pyrrolidone) in a certain mass ratio (1 mg / mL), and dissociated by ultrasonic liquid phase for 2 hours, thereby obtaining Fe 3 GeTe 2 The nanosheets and graphene na...

Embodiment 2

[0051] This embodiment provides a two-dimensional magnetic Fe 3 GeTe 2 Nanosheet and graphene nanosheet composite material, the process of its preparation method is as follows figure 1 It includes the following steps:

[0052] (1) Grinding Fe 3 GeTe 2 Single crystal, to obtain Fe 3 GeTe 2 powder; Fe 3 GeTe 2 The powder was added to acetone (1.5mg / mL), and the ultrasonic liquid phase exfoliation was carried out for 15 hours. The power of ultrasonic liquid phase exfoliation was 600W to obtain Fe. 3 GeTe 2 Nanosheet dispersion.

[0053] (2) Collect Fe by vacuum filtration and washing with deionized water 3 GeTe 2 Nanosheets, dried under vacuum to obtain Fe 3 GeTe 2 Nanosheets;

[0054] (3) Graphite and Fe 3 GeTe 2 The nanosheets were uniformly mixed at a mass ratio of 1:2, added to NMP (1-methyl-2-pyrrolidone) at a certain mass-to-volume ratio (1.5 mg / mL), and dissociated by ultrasonic liquid phase for 4 hours, thereby obtaining Fe 3 GeTe 2 Nanosheets and graphe...

Embodiment 3

[0057] This embodiment provides a two-dimensional magnetic Fe 3 GeTe 2 Nanosheet and graphene nanosheet composite material, the process of its preparation method is as follows figure 1 It includes the following steps:

[0058] (1) Grinding Fe 3 GeTe 2 Single crystal, to obtain Fe 3 GeTe 2 powder; Fe 3 GeTe 2 The powder was added to acetone (0.5mg / mL), and the ultrasonic liquid phase peeling was carried out for 9 hours. The power of ultrasonic liquid phase peeling was 400W, and Fe was obtained. 3 GeTe 2 Nanosheet dispersion.

[0059] (2) Collect Fe by vacuum filtration and washing with deionized water 3 GeTe 2 Nanosheets, dried under vacuum to obtain Fe 3 GeTe 2 Nanosheets;

[0060] (3) Graphite and Fe 3 GeTe 2 The nanosheets were uniformly mixed at a mass ratio of 1:2, added to NMP (1-methyl-2-pyrrolidone) at a certain mass-to-volume ratio (0.5 mg / mL), and dissociated by ultrasonic liquid phase for 1 hour, thereby obtaining Fe 3 GeTe 2 Nanosheets and graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com